It is possible to assign fasteners between subassemblies even if some parts

of a given subassembly are not yet planned or are not loaded in session.

In the scenarios below, the subassemblies are not yet planned or loaded in the

session. The Automatically

Assign and Reassign Fasteners option is selected in

.

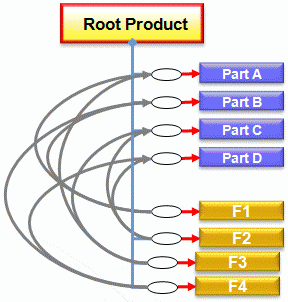

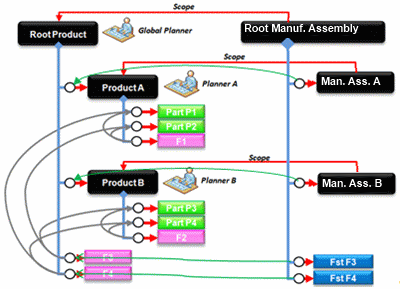

In the following product structure, the root product consists of two subassemblies

(Product A and Product B) that have some

parts and fasteners and are joined together with the fastener F3

(Parts P2 and P3) and the fastener

F4 (Parts P1 and P4).

When launching the fasteners assignment command, only external fasteners are taken

into account, ignoring internal fasteners.

An external fastener is a fastener joining two parts included in two different

subassemblies (fasteners F3 and F4 in the

above structure).

An internal fastener is a fastener joining two parts included in the same subassembly

(fastener F1 inside Product A subassembly or

fastener F2 inside Product B subassembly).

Internal fasteners can be assigned when the local planner starts the command to

assign fasteners for parts within the local area of responsibility.

Subassembly with Scope Link to a Manufacturing Assembly

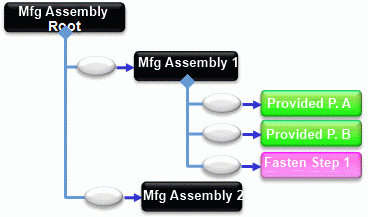

In the following Product/Item structure, the root product was assigned to the

global planner and each subassembly is assigned to a different planner under the

responsibility of the local planner.

Scope links are created between:

- Root Manuf. Assembly and Root

Product

- Man. Ass. A and Product A

- Man. Ass. B and Product B

The local planners A and B must completely

consume the Product node under their responsibility (Product

A and Product B respectively). For the global

planner, once a scope is defined on a product node, it is considered as assigned

and all its products are seen as implemented. When the global planner wants to

assign fasteners for the whole structure, the fasteners joining the

subassemblies must be assigned to the manufacturing item where these

subassemblies are assembled, even if these subassemblies are not yet planned

(planners A and B have not finished their

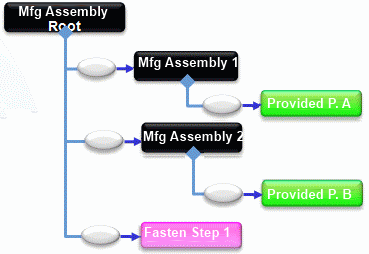

work yet). After launching the fasteners assignment command, the following

structure is created:

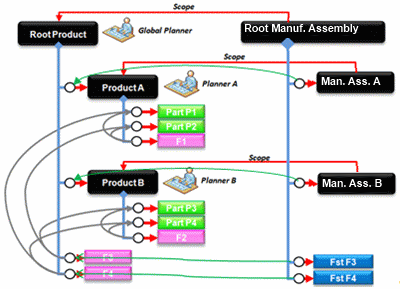

For the global planner, only Fasteners F3 and

F4 are assignable, product nodes A and

B are considered as consumed since a scope link exists.

Fastener F3 joins P2 (under

Product A) and P3 (under

Product B): Fastener F3 joins

Product A and Product B together under

Root Manuf. Assembly. A Fasten step (Fst F3) is created under Root Manuf.

Assembly to implement Fastener F3.

Fastener F4 joins P1 (under

Product A) and P4 (under

Product B): Fastener F4 also joins

Product A and Product B together under

Root Manuf. Assembly. A Fasten step (Fst F4) is created under Root Manuf.

Assembly to implement Fastener F4.

Fastener F1 joins part P1 and

P2 under the same subassembly Product

A: F1 is an internal fastener and it is

ignored.

Fastener F2 joins part P3 and

P4 under the same subassembly Product

B: F2 is an internal fastener and it is

ignored.

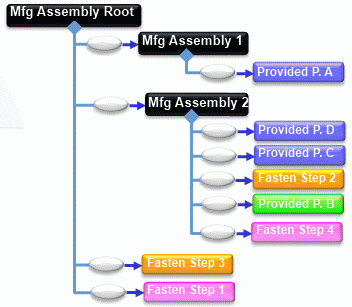

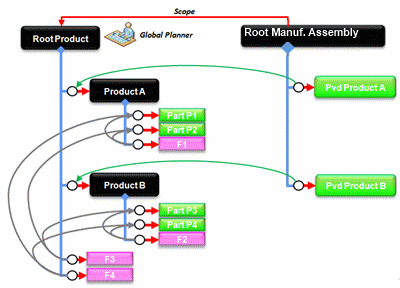

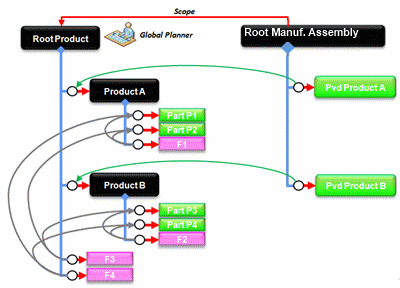

Subassembly Implemented by a Provided Part

In the following Product/Item structure, the Product A and

Product B nodes are assigned directly to the

Root Manuf. Assembly with a Provided Part.

In this case, under the root scope, the Product A and

Product B nodes are seen as completely assigned (all

their internal parts and fasteners are seen as assigned).

When launching the fasteners assignment command on the Root Manuf.

Assembly, these nodes are considered leaf nodes and seen as

assigned. Fasteners F3 and F4 join these

two nodes as they join respectively two parts, each one included in a

subassembly.

Internal fasteners are ignored as they are seen as assigned (parent product is

assigned).

The resulting structure is as follows: