Create and Update Modes of the Command

The Create Manufacturing Assembly command is enabled

when the selected item is a leaf node. The Update Item

Structure command is enabled when the selected item is a nonleaf

node.

A leaf node is a tree node with no children and a nonleaf node is

a tree node with children.

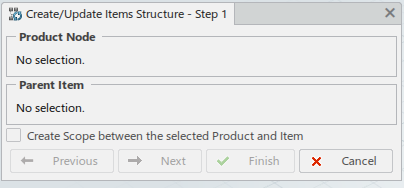

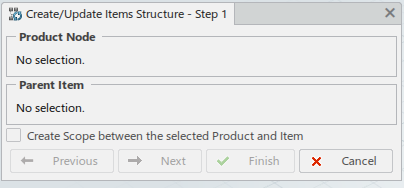

The first step in the procedure is to associate a product with the selected item. If the

selected item has a context link to a product, then that product is taken into

account by the Create Manufacturing Assembly command.

Otherwise you must select a product to create a context link between the product and

the item.

If the Create Scope between the selected Product and Item option is

selected, the scope is created between the selected product and item. Notes:

- If the selected item has an already existing "First Upper Scope" with a

product, the user can use this option to edit the value of the

setting.

- If the selected item does not have a "First Upper Scope" with a product,

this option is selected by default and disabled for the user.

The Update Item Structure command creates additional items

according to the current product structure and selected options. Any already

existing manufacturing subassembly that corresponds to the current product structure

is not modified.

Command Options

A number of options are taken into account during the command

execution. These options may be fixed and cannot be modified depending on the

selected industry mode.

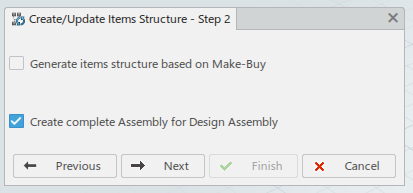

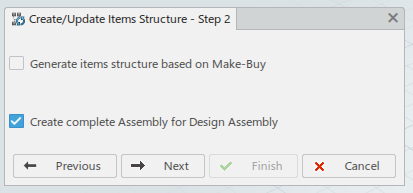

The second step in the procedure is to specify how the Manufacturing Assembly is to be generated.

When selecting the Advanced user (all options) mode in

, the options are presented in the following dialog box:

- Generate Items structure based on Make-Buy

- If this option is selected, extra analysis is carried out and Manufacturing Assembly generation is determined depending on:

- Create complete Assembly for Design Assembly

- If this option is selected, nonleaf product nodes are processed recursively.

- The product leaf nodes have a corresponding Provided Parts

or Fasten steps when conditions are met.

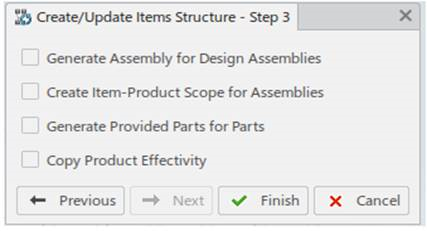

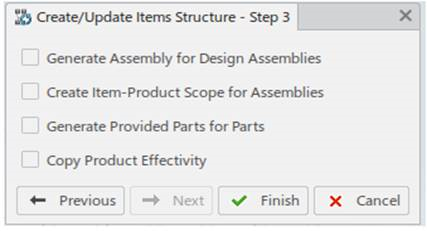

The third and final step in the procedure is to specify how the various items are to be

generated.

When selecting the Advanced user (all options) mode in

, the options are presented in the following dialog box:

- Generate Assembly for Design Assemblies

- If this option is selected, a Manufacturing Assembly is created for the corresponding product node if this node is a

nonleaf node.

- Create Item-Product Scope for Assemblies

- If this option is selected, a scope is created between the product and

the item for each Manufacturing Assembly that is created.

- Generate Provided Parts for Parts

- If this option is selected, Provided Parts are generated for parts.

- Copy Product Effectivity

- If this option is selected, the product's effectivity is copied onto its

implementing items on the leaf nodes.

Notes:

If the product is not declared as

Manufacturable/Procurable, the system does not take into

account the product:

- For a leaf product, no implementing item (generally a provided part) is

created.

- For an intermediate node, the system does not take into account the node

and continues deeper in the structure.

Industry Modes

The selected industry mode has a great influence on how the Manufacturing Assembly is generated. The industry modes are Aerospace,

Administrator, or Advanced user (all

options).

Definition of the Industry Mode

You can specify the Generation mode for

industry in

.

- Working under the authority of an action

- If this option is selected, it lets you manage a single level of the

structure and define effectivities.

- A single level of the structure is a reference with a variability

space and its child instances only.

Advanced User Mode

In Advanced user (all options) mode, the options of the

Create/Update Item Structure command are proposed in

dialog boxes.

If the Generate Items structure based on Make-Buy option (step 2) is

selected, item generation is as follows.

- If the product is considered as Make:

For non-leaf nodes, a Manufacturing Assembly is created and the scope creation is customizable based on the

sCreateScope attribute value:

- If the

sCreateScope attribute value is set

to Yes, the scope is created on the Manufacturing Assembly.

- If the

sCreateScope attribute value is set

to No, the scope is not created.

The non-leaf node's children are processed only if the

Working under the authority of an action

option is cleared.

- If the product is considered as Buy:

A Provided Part is created if the Generate Provided Parts for

Parts option (step 3) is selected. The children of

the product node are ignored.

- If the product is considered as Undefined:

For non-leaf nodes, nothing is created and

the nonleaf node's children are processed only if the

Create complete Assembly for Design

Assembly option (step 2) is selected.

If the Generate Items structure based on Make-Buy option (step 2) is

cleared, item generation is as follows.

Administrator Mode

In Administrator mode, the Generate Items structure based

on Make-Buy option is selected.

- If the product is considered as Make:

For non-leaf nodes, a Manufacturing Assembly is created and the scope creation is customizabled based on the

sCreateScope attribute value:

- If the

sCreateScope attribute value is set

to Yes, the scope is created on the Manufacturing Assembly.

- If the

sCreateScope attribute value is set

to No, the scope is not created.

The non-leaf node's children are processed only if the

Working under the authority of an action

option is cleared.

- If the product is considered as Buy:

No item is created and all the

children of the product node are ignored.

- If the product is considered as Undefined:

No item is created. The

non-leaf node's children are processed.

Note:

The following options are overridden by the rules of the Administrator industry mode: Generate Assemblies for Design

Assemblies, Generate Provided Parts for

Parts, Create Item-Product Scope for

Assemblies, and Create complete Assembly for Design

Assembly.

Aerospace Mode

In Aerospace mode, the Generate Items structure

based on Make-Buy option is selected by default.

- If the product is considered as Make:

For non-leaf nodes, a Manufacturing Assembly is created and the scope creation is customizable based on the

sCreateScope attribute value:

- If the

sCreateScope attribute value is set to

Yes, the scope is created on the Manufacturing Assembly.

- If the

sCreateScope attribute value is set to

No, the scope is not created.

Provided Parts are created for leaf nodes. The nonleaf

node's children are processed only if the Working under the

authority of an action option is cleared.

- If the product is considered as Buy:

A Provided Part is created and all the children of the product node are

ignored.

- If the product is considered as Undefined:

No item is created for nonleaf

nodes and no items are created for leaf nodes. The children are

processed only in nonleaf nodes.

The Generate Single Provided Part Reference for Multiple Instantiated

Parts option is active in Aerospace mode,

so a Provided Part reference is created for multiple instantiated parts.

Note:

The following options are overridden by the rules of the Aerospace industry

mode: Generate Assemblies for Design Assemblies,

Generate Provided Parts for Parts, Create

Item-Product Scope for Assemblies, and Create

complete Assembly for Design Assembly.

Make/Buy Management Using Business Logic

When a product or part is considered as either Make or Buy, the program can determine

the item creation characteristics. The Make or Buy characteristics can be determined

thanks to the dedicated DELMA_MakeOrBuyTesting business logic.

A MakeOrBuyTesting parameter is available in DELMA_MakeOrBuyTesting

for Make or Buy processing. Processing can be applied on a product or part and the

business rule looks for the required Make, Buy, or Undefined information located in

the object. This information can be used when creating and updating Manufacturing

Assemblies.

Parent Customization Using Business Logic

By default, the Create/Update Item Structure command assigns all

products and parts under the selected product to its implementing item. The

DELMA_ChooseParentInCUPS business logic enables you to choose the

parent item based on attribute value.

The

product

instance to assign and the

item instance you want to choose as parent must both have the same value

for the

Description attribute.

When you use the Create/Update Item Structure command, the DELMA_ChooseParentInCUPS

business logic is executed with the following steps:

- The business logic retrieves the implementing item of the selected product.

- From the implementing item, the business logic moves upward in the PPR tree,

while remaining under the first upper-scoped item, until it encounters an

item with the same attribute value as the product.

- This item is chosen as parent, under which the Create/Update Item

Structure command creates, or repositions items.

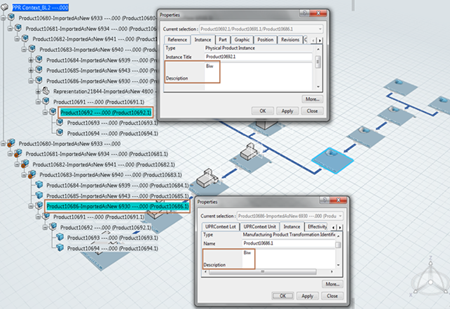

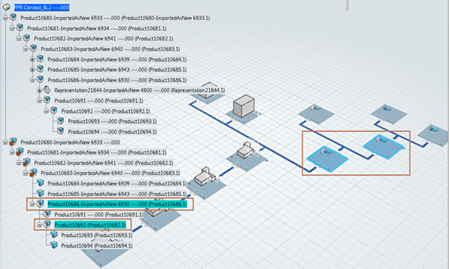

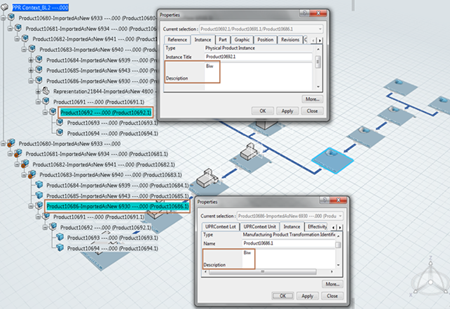

In the example below:

- The selected product Product10692 is implemented by the item

Product10692.

- From the implementing item Product10692, the first

upper-scoped item is Product10683-ImportedAsNew

6930.

- The item Product10686-ImportedAsNew 6930 is under the first

upper-scoped item, and has the same value for the

Definition attribute as the selected product

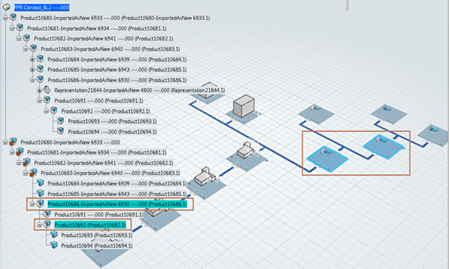

The Create/Update Item Structure executes the business logic. It moves

upward the tree from the implementing item

Product10692, while remaining under the first

upper-scoped item. The item Product10686-ImportedAsNew

6930 is the first encountered object with the same attribute

value as the selected product.

As a result, Product10686-ImportedAsNew 6930 is chosen as parent

for the implementing item Product10692. The MBOM structure is

updated.

|