Strategy Parameters | ||

| ||

![]()

Strategy Parameters

- Tool Axis

The Tool Axis command in the Turning Operations dialog box is represented by an arrow when creating a part operation.

See Defining the Tool Axis

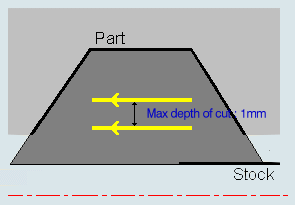

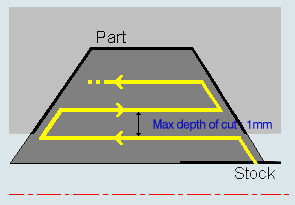

- Max Depth of Cut

- Specifies the maximum distance between passes.

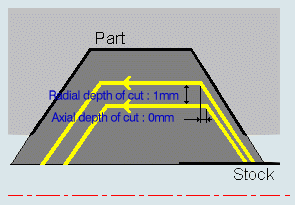

- Axial and Radial Depth of Cut

- Specifies the maximum axial and radial distances between passes for

Parallel Contour mode.

This is available when Recessing Mode is Parallel Contour.

- Recessing Mode

- Specifies the recessing mode.

You can specify:

- Orientation

- Specifies orientation.

The selected orientation defines the type of geometric relimitation to be done between the rough stock and part geometry in order to determine the area to machine. The following Orientations are proposed:

- Machining Direction

- Specifies the machining direction.

For Zig Zag mode, you must specify a first cutting direction as follows:

- To Head rough stock or From Head rough stock for Internal and External orientation.

- To Spindle or From Spindle for Frontal orientation.

- Right of Groove or Left of Groove for Other orientation.

When a part profile has multiple recesses (that is, a non-convex profile along the cutting direction), only the first recess along the specified direction is machined.

- Under Spindle Axis Machining

- Select this check box to request machining under the spindle axis.

This option is available for Frontal or Other orientation.

- Part Contouring

- Select this check box if contouring is required.

The part profile is followed at the end of Recess Turning. This is done by machining down the sides of the recess in order to clear the profile.

- Lift-off distance

- Part Clearance

- Part Geometry

- Tool Compensation

- Select a tool compensation number corresponding

to the desired tool output point.

The usable compensation numbers are defined on the tool assembly linked to the machining operation.

By default, the output point corresponding to type P9 is used, if you do not select a tool compensation number.

- Change Output

- Select the Change Output Point check box to

automatically manage the change of output point. .

If the output point is consistent with the flank of the recess to be machined, the output point is changed when the other flank of the recess is machined.

At the end of the Machining Operation, the output point is the same as it was at the start of the Machining Operation. See Tool Output Point Change.

Options

- Lead-in Distance

- Specifies lead-in distance with respect to the cutting direction.

It takes the rough stock profile and rough stock clearance into account. The tool is in RAPID mode before this distance.

- Attack Distance

- Specifies attach distance with respect to the cutting direction and the rough stock profile with a rough stock clearance.

- Angle and Distance before Plunge

- Specifies the plunge vector before each new pass with respect to the cutting direction.

- Lift-off Distance and Lift-off Angle

- Specifies the lift-off vector with respect to the cutting direction.

- at the end of Each pass

- or When tool engaged

Lift-off can also be set to None.

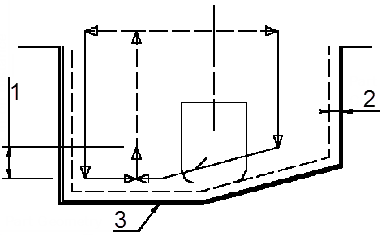

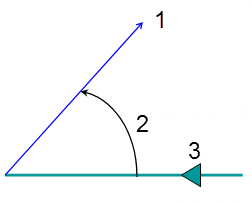

The figure below shows the effect of a positive lift-off angle for external machining.

- Lift-off vector

- Positive lift-off angle

- Cutting direction

- Leading and Trailing Safety Angles

- Leading and Trailing Safety Angles are for

One Way and Parallel

Contour modes. The insert geometry is taken into account

to avoid collision by reducing the maximum slope on which the tool can

machine. The Leading and Trailing Safety Angles

allow you to further reduce this slope.

Leading and Trailing Safety Angles can also be defined on the insert-holder to define the maximum slope on which machining is done. In this case and if the Insert-Holder Constraints setting is applied, the angles that reduce the slope most is taken into account.

- Gouging Safety Angle

- Specifies the Gouging Safety Angle.

This option is available for Zig Zag recessing mode only. Angles of the insert are taken into account to avoid collision by reducing the maximum slope on which the tool can machine. The Gouging Safety Angle allows you to further reduce this slope.

A gouging angle can also be defined on the insert-holder to define the maximum slope on which the tool can machine. In this case and if the Insert-Holder Constraints setting is applied, the angle that reduces the slope most is taken into account.

- Insert-Holder Constraints

- Specifies insert-holder constraints as:

- Ignore

- Apply

The following attributes (located on the Insert-holder's Technology tab) may influence machining: See Creating and Editing Milling, Drilling, and Probing Tools:

- Gouging angle

- Trailing angle

- Leading angle

- Maximum recessing depth

- Maximum cutting depth

- Maximum boring depth

These attributes take tooling accessibility into account and may reduce the machined area. However, you can use the Insert-Holder Constraints option to either ignore or apply these tooling attributes. You can replay the operation to verify the influence of these attributes on the generated tool path.

The Insert-Holder Constraints setting does not influence the Gouging Safety Angle or the Leading and Trailing Safety Angles.

- Machining Tolerance

- Specifies the maximum allowed distance between the theoretical and computed tool path.