Create Milling, Drilling, and Probing Tools

You can create tools such as end mills, spot drills, and ball stylus tools. This task

illustrates the creation of an end mill tool. Dialog box names depend on the type of tool you

create.

-

From the

Setup section of the action bar,

click Resource Creation

. .

The Resource Creation dialog box appears with expandable

areas such as:

- Milling Tools

- Drilling Tools

- Probing Tools

- Optional:

In the Resource Creation dialog box, click

to search a

tool from the Tool Search panel. For more information, see Tool Search to search a

tool from the Tool Search panel. For more information, see Tool Search

-

Expand the

Milling Tools area and select Creates End Mill

Tool

. .

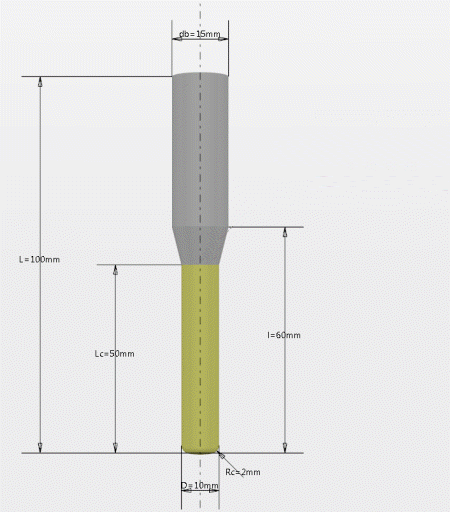

The tool appears in the work area

with values corresponding to the default tool dimensions.  - Optional:

In the NC Resource dialog box, enter a new name and comment for

the tool.

-

In the work area,

double-click a value to modify it.

-

In the Edit Parameter dialog box, enter a new value.

-

Click OK to update the tool with the new value.

-

Modify other values in the same way.

-

To specify other

parameters of the tool, click Edit parameters

in

the End Mill Tool area of the NC Resource

dialog box. in

the End Mill Tool area of the NC Resource

dialog box.

A dialog box appears with expandable areas such as:

- Geometry

- Technology

- Feeds & Speeds

- Compensation

- Attachment

- Part Body Color

-

To select a holder, click Add Holder then choose a holder selection

option.

-

Modify the required parameters and click OK.

-

To finish, click

OK in the NC Resource dialog box.

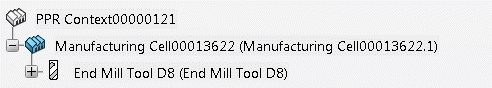

You created the end mill tool and it appears in the tree under the manufacturing cell.

Create Mill Insert Holders

You can create an empty mill insert holder for milling and drilling items. This task

illustrates the creation of an insert holder with an end mill tool.

-

From the

Setup section of the action bar,

click Resource Creation

. .

The Resource Creation dialog box appears with expandable

areas such as:

- Milling Tools

- Drilling Tools

- Probing Tools

- Optional:

In the Resource Creation dialog box, click <image> to

search a tool from the Tool Search panel. For more information, see

Tool Search

-

Expand the Milling Tools area and select Creates Mill

Insert Holder

, then Creates End Mill Tool , then Creates End Mill Tool

. .

The insert holder appears in the work area

with values corresponding to the default tool dimensions.

- Optional:

In the NC Resource dialog box, enter a new name and comment for

the insert holder.

-

Select the nocut user representation of the insert holder.

This contains the axis systems where the inserts can be mounted. For more information,

see Define User Representation.

-

Define the gauge insert REF to specify the compatible inserts

that can be mounted.

-

Click OK in the NC Resource dialog

box.

The end mill tool insert holder appears in the tree under the manufacturing cell. Note:

To mount inserts to the tool holder, create a tool

assembly.

Create a Multi-Diameter Drill Tool with Multiple Stages

You can create a multi-diameter drill tool with more than 3 stages.

-

From the

Setup section of the action bar,

click Resource Creation

. .

The Resource Creation dialog box appears with expandable

areas such as:

- Milling Tools

- Drilling Tools

- Probing Tools

-

Expand the Drilling Tools area and select Create

Multi Diameter Drill Tool

. .

The tool appears in the work area

with values corresponding to the default tool dimensions.

- Optional:

In the NC Resource dialog box, enter a new name and comment for

the tool.

A dialog box appears with expandable areas such as:

- Geometry

- Technology

- Feeds & Speeds

- Compensation

- Attachment

- Part Body Color

-

Expand the Geometry area, and specify the required number of

stages.

The following fields appear and are dynamically created for each additional

stage: Stage length, Stage diameter, and

Stage taper angle. Compensation correctors associated to each

stage from the fourth stage onwards appear. For the fourth stage: P10, P11, and P12

correctors appear. For the fifth stage: P13, P14, and P15 correctors

appear. Point length, Point

diameter, and Tool diameter are visible for all

stages and display the distance from the point to the mount point or tip point. These

values are calculated automatically according to the parameter inputs in the

Geometry area. -

When a user-representation is added, you can also compute the rotary profile of a

tool from the Manage Representation panel.

-

For an existing rotary representation, click Upgrade

Rotary.

Note:

The rotary part remains the same, only features inside the rotary part are

modified.

-

To create a rotary representation with the new profile computation, click

Generate Rotary.

-

To select a holder, click Add Holder then choose a holder selection

option.

-

Modify the required parameters and click OK.

-

To finish, click

OK in the NC Resource dialog box.

Edit a Tool

You can edit a tool from the manufacturing cell.

|