Create a Synchronization at the Machining Operation Level

You can create/edit a machining operation level synchronization from the Dock/Global

View.

-

Select MO Level check box.

-

For each Machining Operation, select a position (Start, End,

End of Approach, and Start of Retract)

from the list below.

The position indicates whether the synchronization is set at the start of the

selected Machining Operation or at the end of the above Machining Operation. When you run the simulation the simulation run as per the position of

synchronization. Note:

End of Approach and Start of

Retract positions are supported only for Turning

operations.

-

Select a turret from the list at the bottom of the dialog box.

The selected turret becomes the primary turret.

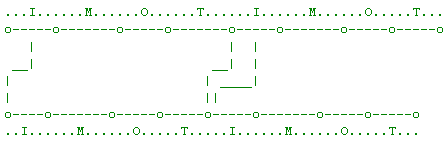

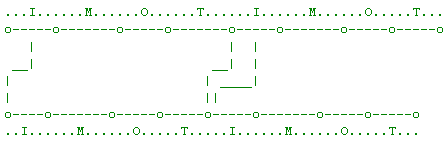

| Time |

T1 (Turret_Product) |

Synchronization |

T2 (Turret_Product) |

| 0s |

Turning Tool Change.4 |

|

Turning Tool change.8 |

| 0.648s |

|

|

External Roughing2 |

| 831.386s |

|

|

Turning Tool change.7 |

| 964.007s |

|

|

Drilling.3 |

| 964.565s |

External Roughing |

|

Turning Tool Change.5 |

| 964.583 |

|

X<---S1---> |

|

| 1795.285s |

Turning Tool Change.5 |

|

|

| 1795.843s |

Drilling.5 |

|

Rough Turning |

| 1795.861s |

|

X<---S2---> |

|

Right-clicking on Drilling.5 shows: Begin Time:

1795.843s, duration 132.1s, End time: 1927.943s, Spindle number: 1, Spindle Name:

Spindle_Product 384... Right-clicking on X<--S2--> shows: Synchronization

2, Time: 1.061E-314, Drilling.5 (Start), Primary: Turret_Product

38143.1 -

Click OK to validate the synchronization.

An error appears if the synchronization fails between two Machining Operations.

-

Place the pointer over the Synchronization column or over a

Machining Operation to display synchronization information as a tooltip.

-

Double-click arrow X<---...---> in the Synchronization

column in Dock/Global View, to edit the existing synchronization.

-

Click Preview to display the turrets in the position

corresponding to the currently defined synchronization.

-

Click Cancel to close the Synchronization

dialog box without changes.

Create a Synchronization at the Pass Level

You can create/edit a Pass level synchronization from the Dock/Global

View.

-

In the Select Synchronization dialog box, select

Pass Level check box to create the synchronization across two

different Turning operations.

-

Select two turning operations, say External Roughing and

Rough Turning.

-

Select a Lagging activity.

Lagging activity is the turning operation whose passes in the tool path lag the passes in the

tool path of the other turning operation.

-

Select an End point option from the list to create the

synchronization.

- None: No synchronization at the end of passes and tool path

behaves as:

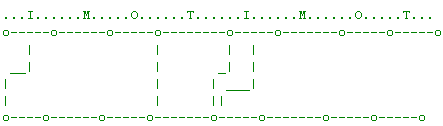

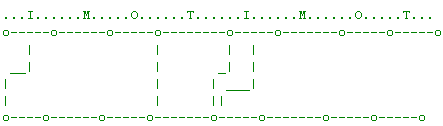

Start of Lead-In: None I = Lead-In, O = Lift-Off, M = Machining, T =

Transition

- End Of Lift-Off: This creates a synchronization at the end

of passes and tool path behaves as:

Start of Lead-In: End of Lift-Off I = Lead-In, O = Lift-Off, M =

Machining, T = Transition

-

Specify the Delay distance.

The delay distance allows the pass on the lagging operation to start a small

distance after the pass of the other operation has started.

-

Select Retract at once check box to start Lift-Off motion of

the last pass of both turning operations simultaneously.

-

Select a turret from the list at the bottom of the dialog box.

-

Click OK to validate the synchronization.

See APT output for Pass Level synchronization in APT Syntax for

Synchronization..

An error appears if the synchronization fails between two turning operations.

- External Roughing (from the T1 column from above) - Begin

Time: , Duration, End Time:, Spindle number:1, Spindle Name:

Spindle_Product38142.1, Spindle Rotation: AntiClockWise

- Synchronisation 1 (from the Synchronization column above)

- Pass Level Lagging activity: External Roughing, Delay distance: 1, End point;

End of Lift-Off, Time: 7.3149e-177, External Roughing (Start), Rough Turning

(Start), Primary: Turret_Product 38143

The pass level synchronization is represented in Global View by an arrow and with an

icon prior to the arrow. icon prior to the arrow.

-

Place the pointer over the Synchronization column or over a

Machining Operation to display the synchronization information as a tooltip.

-

Double-click arrow

in the Synchronization column in Dock/Global View, to edit the

existing synchronization. in the Synchronization column in Dock/Global View, to edit the

existing synchronization.

-

Click Preview to display the turrets in the position

corresponding to the currently defined synchronization.

-

Click Cancel to close the Synchronization

dialog box without changes.

Preview Synchronization in Global View

You can expand the Global View for synchronization.

-

Click

at the top-right of window to expand Global View of all

synchronization. at the top-right of window to expand Global View of all

synchronization.

By default, the Global View presenting all the Machining Operations and synchronizations is docked. Only information on current activity,

synchronization, times, and percentage working of turrets are visible.

The Global View displays all the operations on each turret, all synchronizations, and

times.

The busy time is represented by a green line  when the same Machining Operation is repeated and the idle time is represented by an hourglass

when the same Machining Operation is repeated and the idle time is represented by an hourglass  . .

The Duration time column is hidden.

-

Click

to revert to the Dock View again. to revert to the Dock View again.

Switch to a Predefined Turning View

This provides the capability to view the geometry to be machined in a Turning view.

Select Turning View from the View Section: Primary

Area to view the part operation to be machined.

Launch Simulation

You can use simulation player to interact with the simulation.

Click buttons in Simulation Player to interact with the

simulation, launch/stop the simulation, and edit the current time.

Update Times

To avoid time-consuming updated, times are updated only on request, when all

synchronisations have been created or edited and visualized.

When you have finished creating or edition synchronization, click

Update

.

Update is grayed when the times are up-to-date and red when a

time update is required. The times are updated, and the Simulation Player is now

available.

Navigate in the Operations/Synchronisation

You can go to next/previous Machining Operation/synchronization.

-

Select the type of navigation in the navigation box, available at the lower right of

the 3DEXPERIENCE platform.

-

Use the arrows to go from one entity to the other.

Check Report During Synchronization

You can view warning or error messages in the Messages

Reporting dialog box launched during simulation.

-

Click Simulation Options

(middle of the right side of the screen) to define simulation criteria. (middle of the right side of the screen) to define simulation criteria.

-

Click Messages Reporting

(immediately beneath Simulation Options) to

read any warning or error messages. (immediately beneath Simulation Options) to

read any warning or error messages.

The dialog box is updated at the beginning of the command and each time you refresh

the time based information by clicking the Update

button. button.

Messages are displayed when:

- The tool path of a Machining Operation is not computed. Compute the tool path

- Two Machining Operations work simultaneously on the same spindle. Their rotation states are

incompatible. Synchronize the operations.

- Two Machining Operations work simultaneously on the same spindle with different spindle rotation

directions. Either:

- Synchronize the Machining Operations,

- Or modify their properties,

- Or modify their tooling.

- Two turrets are working simultaneously on one spindle and no primary turret has

been defined. Synchronize them and/or define the primary turret.

- Several turrets are working simultaneously on one spindle, during a given time,

and no primary turret has been defined. Synchronize them and/or define

the primary turret.

- The secondary turret starts before the primary turret. Synchronize

them and/or define the primary turret.

See Using Multi-Slide Lathe Machines, Using the APT Syntax for Synchronization,

Profile Finish Turning, Using Synchronization at a Pass Level

|

icon prior to the arrow.

icon prior to the arrow. in the Synchronization column in Dock/Global View, to edit the

existing synchronization.

in the Synchronization column in Dock/Global View, to edit the

existing synchronization.