Using Multi-Slide Lathe Machines | ||

| ||

Spindle Definition

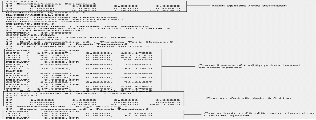

When you select the Spindle tab in the Generic Machine dialog box, the following dialog box appears.

- On the left, there is a list of spindles with Add/Remove options to add or remove these entities.

- On the right, properties of the selected spindle are displayed.

- Name

- Each spindle has a name. When there is more than one spindle

defined on the machine, then spindle name is displayed at the bottom of the

Part

Operation dialog box.

By default, single spindle is used and is output in APT in place of MFG_SPINDLE_NAME.

- Number

- Each spindle has a number, which is written in valuated in APT in place of MFG_SPINDLE_NUMBER. Spindle name and number are valuated in NC_MACHINING_AXIS and NC_ACTIVITY_HEADER syntaxes.

- Part Axis System

- Part Axis System defines the plane where Simulate or Display and time-based replay are represented.

- Spindle Axis

- Specifies the spindle axis.

- Radial Axis

- Specifies the radial axis.

- Max Spindle Speed

- Specifies the maximum spindle speed.

Counter Spindle Output

Counter spindle output is managed by the Use Spindle Axis system defined in the Machining Operation check box in the Option tab of the Generic Machine dialog box. This is for a Multi-slide lathe machine or a Mill-Turn machine. See Creating a Part Operation

The Use Spindle Axis system defined in the Machining Operation check box provides tool path points or coordinates of the tool positions of the tool path for Machining Operations defined on the counter spindle with respect to Counter Spindle Part axis system. Machining axis change definition is avoided.

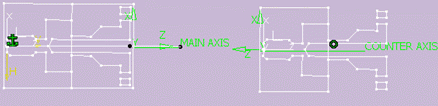

Example of a Multi-Slide Lathe Machine setup showing main and counter spindles:

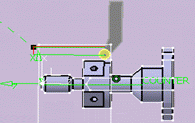

If a program is defined with a Machining Operation on the main spindle, and a second Machining Operation on the counter spindle, here is a typical replay of the Machining Operation defined on the counter spindle:

Tooltip positions seen in the tool path replay panel are based on counter spindle axis.

Sample of the APT output obtained for the program:

Some counter spindle capabilities are:

- Counter Spindle is defined at any angle to Main Spindle axis.

- The tool path on the counter spindle is in the turret plane, even if the Counter Spindle Part axis system is rotated by an angle (that is, if the counter spindle plane is not at zero degrees).

Turret Definition

Select the Turret tab in Generic Machine dialog box.

- On the left, there is a list of turrets with Add/Remove options to add or remove these entities.

- On the right, properties of the selected turret are displayed.

- Name

- Each turret has a name, which is displayed in the Activities Process tree next to the Manufacturing Program with which it is associated. See Assigning Manufacturing Programs to the Turrets

- Number

- Each turret has a number, which is output in APT output in place of MFG_CHANNEL_NUMBER in the program header or synchronization syntax.

- Type

-

Turret Type defines the turret type as:

- Rotary Turret

- Mill Turret, turret that has B-axis capability

When you assign a machine to a part operation, the turret type is set to Rotary. This is done to maintain compatibility with the previous version because if the turret type is changed automatically from Rotary to Mill then the APT source can contain B-axis and C-axis information. Moreover, Simulate or Display and simulation can also consider the B and C axes and use the Setup angle to simulate the B-axis.

When the turret type is set to Mill Turret, you can specify that the B-axis value be defined by the machine instruction within a manufacturing program by selecting Tool Axis from machine instruction in the strategy parameters tab. The B-axis valued defined in the machining operation will be considered a delta value on top of the B-axis value obtained from machine instruction. For more information, see B-Axis Management and Tool Axis Flip.

- Specifies the

Turning Tool Axis System by clicking

.

.

- Tool Change point

- Tool Change point is defined manually through its absolute coordinates (X,Y,Z). Since this point might be considered as the origin of the Turning Tool Axis System, you can use the option at the bottom of the Generic Machine dialog box to automatically set it.

See Axis Systems.