Create and Edit a Part Operation

You can access and create a Part Operation in the Activities Process Tree.

-

From

any product or 3D part:

-

Select a machining app then the Programming section.

A PPR Context with an empty Manufacturing

Cell is created with a Activities Process

Tree.

-

Create a generic machine or assign a

machine from the database.

As soon as a

machine is assigned to the Manufacturing

Cell, a Part Operation and a Manufacturing Program are created in the Activities Process

Tree.

-

Alternatively, open an existing

Machining Process or PPR Context.

By default, the Activities Process

Tree is available.

-

Select a machining

app

then the

Programming

section.

An empty

Manufacturing

Cell is created with an

Activities Process

Tree.

-

Create a generic machine or assign a

machine from the database.

As soon as a

machine is assigned to the

Manufacturing

Cell,

a

Part Operation

and a

Manufacturing Program

are created in the

Activities Process

Tree.

-

Alternatively, open an existing

Machining Process

or

PPR Context.

By default, the

Activities Process

Tree

is available.

-

If you need to add a Part Operation, click Part Operation

. .

-

Double-click the Part Operation in the Activities Process Tree.

The dialog box to edit a Part Operation varies depending on the type of the machine.

- When the assigned machine is a milling machine, the Part Operation is:

- When the assigned machine is a mill turn machine, the Part Operation is:

- When the assigned machine is a wire EDM machine, the Part Operation is:

- Optional:

Click Comment

to edit

the Part Operation Name and assign Comments to the Part Operation. to edit

the Part Operation Name and assign Comments to the Part Operation.

- Optional:

Edit the Setup

Options, and Transition Path tabs.

-

Optional: Edit the Air Cut Optimization

parameter.

- If activated: Removes cutting motion when the tool does not remove

any material, reducing machining time.

- If deactivated: Keeps cutting motion when the tool does not remove

any material, reducing computation time.

-

Click Analyze

to open the Geometry Analyzer dialog box containing the

selected geometry points.

to open the Geometry Analyzer dialog box containing the

selected geometry points.

-

Click Reset all selections

to reset all geometry selections in the 3DEXPERIENCE platform.

to reset all geometry selections in the 3DEXPERIENCE platform.

-

Click Define Feature to Recognize

to select the faces of the feature to recognize for geometric form reuse. to select the faces of the feature to recognize for geometric form reuse.

Note:

If the part contains several geometric forms, you must define a setup

and a new NC assembly for each form on the part.

-

Click Show/Hide the offset

to show/hide the offsets in 3DEXPERIENCE platform.

to show/hide the offsets in 3DEXPERIENCE platform.

Assign a Reference Machining Axis System

You can assign a reference machining axis system to the Part Operation.

-

Click Reference Machining

Axis System

. .

The Machining Axis System dialog box is

displayed.

-

See Inserting Machining Axis Changes.

Notes:

- Output coordinates are expressed in the reference machining axis system.

- If a local machining axis system is inserted in the Manufacturing Program, coordinates are expressed in the local axis system.

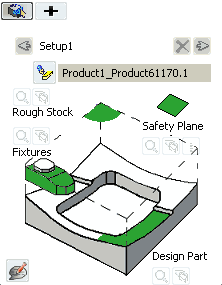

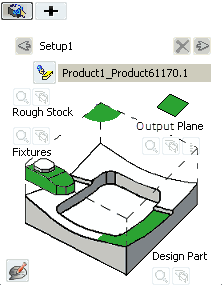

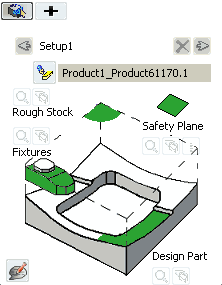

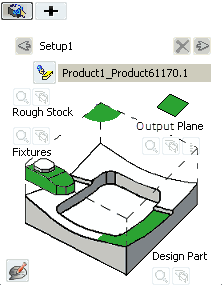

Define the Setup of the Part Operation

You can define the geometry of the Setup Assembly, the Design, the Stock,

Check elements and Safety planes from the Setup

tab.

Note:

Sketches are not supported to define design parts, stocks, or fixtures.

-

Go to the

Setup

tab

. .

-

Assign

an existing setup assembly to the Part Operation.

-

Click Setup

Assembly

to associate an existing setup assembly to

the Part Operation. to associate an existing setup assembly to

the Part Operation.

Note:

The setup assembly can be linked to only one setup position.

To select the same setup assembly, create a new instance under

the manufacturing cell using the Insert Setup Assembly

command or copying/pasting an existing instance.

The icon turns to  .

-

If required, click

to remove the currently associated setup assembly. to remove the currently associated setup assembly.

The icon turns back to  .

Note:

When replacing the Product or the Part, a warning message is displayed

if points have been created in the machining program . For example: When

defining the order of the pocket in a roughing operation, delimiting the

curve guide in tube machining, or defining the point to probe in a

multi-point probing operation. You can:

- Delete these points: The operations associated to these

points are incomplete and select new points again

- Keep these points: The new product/part of the part operation is

identical.

-

Click Design Part

then select the required geometry.

Recommendation:

You should define a solid as a part, and not

only surfaces.

The geometry of the design part is associated to the Part Operation. This is useful for material removal simulations.

-

Click

stock then select the required geometry.

A rough stock is associated to the Part Operation. This is useful for some Surface Machining Operations and also for material removal simulations.

-

Click

Fixtures then select the required geometry.

Fixtures are associated to the Part Operation. This is useful when you want to do material removal simulations.

-

Click Safety

Plane then select the required plane.

This plane is associated to the Part Operation, as its global safety plane. Note:

For wire EDM

operations, this parameter is replaced by the Output

Plane. This plane defines the height of the tool path on

the Z-axis.

- Optional:

Specify a feeds and speeds configuration to filter the search results of

cutting resources when launched from Search from

Session, Search from Catalog, or

Search from Database in the operation panel.

Note:

The lists displays what is defined under

.

The values are undefined by default, that is, no filter is applied to the

search results based on the feeds and speeds configuration.

If at least one value is defined, resources that have a feeds and speeds

configuration that matches the value specified on setup are included in

the search results. Conversely, resources without a feeds and speeds

configuration are excluded from the search results.

-

Click

+ to add a Setup.

A Setup

tab is added.

-

Click the left or right arrow to modify the order of the existing setups.

-

Click the red cross to delete an existing setup.

-

Right-click

then Reference Machining Axis

System then Reference Machining Axis

System

on Part Operation

Setup

tab:

on Part Operation

Setup

tab:

-

Click Table Center

Setup and modify the reference positions.

Setup delta X 4.00 mm, SetUp delta Y 0.00mm, SetUp delta 0.00mm.

-

Click OK.

Edit the Options of the Part Operation

You can edit several options of the Part Operation from the Option tab.

-

Go to

the Option tab

. .

Only the relevant options are selectable:

Tool Path points

based on the turret axis system, and Collision

Checking, On geometries, Collisions check in on design part.

-

In General:

-

Define the value of the

Stocks Accuracy.

The Stock Accuracy is the tolerance used to

compute tessellations for material removal simulations. By

default, The Stock Accuracy is set to 0.2

mm.

-

For wire EDM operations, define the value of the Machine

Upper Head Height.

The Machine Upper Head Height defines the

output of the upper guide height, which is used by the

post-processor to compute U and V machine values.

-

Click Undo

to revert to the default value. to revert to the default value.

-

Select the required check boxes:

- Use

Spindle Axis System defined in the Machining

Operation: When selected, computes the

tooltip points based on the spindle that is set on the

Machining Operation. If this check box is not selected, the main spindle axis

is used. This is determined by the default reference

machining axis system set on the Part Operation.

Note:

Select a multi-slide lathe machine or a mill-turn

machine.

- Toolpath

points based on the turret axis system: When

selected, computes the tool path points and APT output based

on the turret axis system for turning operations.

By

default, this check box is cleared and the tool path

points and APT output are computed with respect to

Part Operation axis system, in the spindle plane.

-

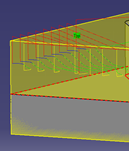

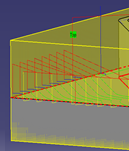

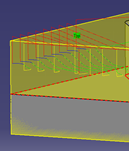

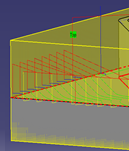

In Intermediate Stock:

-

Select Activate the Intermediate Stock check

box to enable the automatic computation of the intermediate stock.

When the tool path is computed, dynamic

residual stock is computed at the same time, therefore a tool path

without collisions with stock, with minimum NC macro modifications. In this

example:

- In the first level, the linking motions are

created above the stock.

- In the last level, the linking motions are created in the

first level and the stock clearance defined in the

Intermediate Stock of the

Part Operation.

-

Define the value of the

Stock Clearance.

By default, the Stock Clearance is set to

5.00 mm.

-

In Collision Checking:

-

Select the Activate

collisions checking check box to get quick feedback

about collisions during the tool path computation.

Note:

Barrel tools and boring bars are not supported.

-

Select the On design part check box to

detect collisions between the tool/tool holder and the design part

specified in the Part Operation

Geometry tab.

-

Select the On fixtures check box to detect

collisions between the tool/tool holder and the fixtures specified

in the Part Operation

Geometry tab.

-

Select the Collisions Checking with Machine

Head. If the machine head is complex and the tool

path size is large, collision checking may be long, especially with

tight machining tolerance.

- The machine head collision checking requires the machine

kinematic so only the machine head mounted on MTB milling

machine is supported. This includes machine heads on milling

machines.

- Generic and Mill turn machines are not supported.

- Interchangeable head is not supported.

- The system does not know what happened before the first

point of the current operation and the machine configuration

for the first point corresponds to the one resulting of a

motion from the Home position to this first point.

Therefore, the machine configuration for the first point may

differ from the actual one resulting from previous

operations and machine instructions.

- If some tool path positions are not reachable, a warning is

displayed Collision checking is not complete due

to some unreachable positions.

- Optional:

Set offsets on the tool or tool assembly, which are used as safety distances.

-

Set the Minimum

depth collision detection value.

Applying negative offsets on part surfaces, drive curves, or

surfaces leads to the detection of too many collisions, with the

display of unwanted warnings. Setting the Minimum depth

collision detection enables you to set a threshold

under which collisions are not detected nor displayed. While

Minimum depth collision detection has no

maximum value, it cannot be greater than the tool corner radius

defined in the Machining Operation. By default, these values are set to 0mm.

-

In Kinematics Checking:

-

Select the Activate Kinematics Checking to

consider Machine kinematics constraints at tool path computation

time.

-

Define the value of the Max Variation on Rotary

DOF.

By default, the Max Variation on Rotary

DOF is set to 45.00 deg.

-

Define the value of the Stocks

Accuracy.

The Stock Accuracy is the tolerance used to compute

tessellations for material removal simulations. By default, the

Stock Accuracy is set to 0.2 mm.

-

Click to revert to the default value.

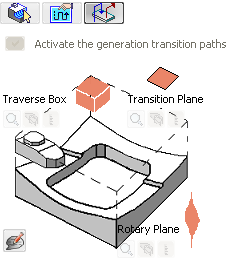

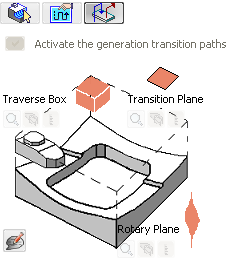

Activate the Generation of Transition Paths

Except for a mill-turn or a lathe machine, you can activate the generation of

transition paths from the Transition Path tab.

-

Select Transition Path

. .

-

Select the Activate the generation Transition Paths

check box.

The icons used to specify the required geometry become available.

Note:

When the check box Generate Transition Path is:

- Selected: The Manufacturing Program

context menu items Generate Machine Rotations and

Delete Generated Machine Rotations

are not available. All the generated machine rotations are removed

from the Activities Process Tree.

- Cleared: The Manufacturing Program

context menu items Generate Machine Rotations and

Delete Generated Machine Rotations

are available.

- See Inserting Machine Rotations.

-

Click Traverse Box

Plane, then select five planes that define a global traverse

box for the Part Operation.

-

Click

Transition Plane, then select the planes that are

used as a global transition planes for the Part Operation.

-

Click Rotary

Plane, then select the planes that is used as a global

rotary plane for the Part Operation.

Select the Milling Head Mount Point from a List

When you select a head, the available mount points are listed, then you can

select one of those mounting points for the Part Operation.

-

In the Activities Process Tree, right-click a Head Change operation.

-

Select the required head from the list of available mount points, such as

Mount_Point_1.

Note:

The machine simulation uses the selected head mount point and also

checks reachability.

See also Inserting Head Changes.

|

.

.

to edit

the Part Operation Name and assign Comments to the Part Operation.

to edit

the Part Operation Name and assign Comments to the Part Operation.

to open the Geometry Analyzer dialog box containing the

selected geometry points.

to open the Geometry Analyzer dialog box containing the

selected geometry points.

to reset all geometry selections in the 3DEXPERIENCE platform.

to reset all geometry selections in the 3DEXPERIENCE platform.

to select the faces of the feature to recognize for geometric form reuse.

Note: If the part contains several geometric forms, you must define a setup and a new NC assembly for each form on the part.

to select the faces of the feature to recognize for geometric form reuse.

Note: If the part contains several geometric forms, you must define a setup and a new NC assembly for each form on the part. to show/hide the offsets in 3DEXPERIENCE platform.

to show/hide the offsets in 3DEXPERIENCE platform.