-

From the Analysis &

Output section of the action bar, click Design Part Comparison

.

.

-

In the Design Part Comparison dialog box that appears,

specify the Tolerance. The value is defined as 0.1mm by

default.

-

Specify the Offset. For more information, see Offset.

- Optional:

Select Ignore Uncut Areas to ignore uncut areas of the

current rough stock during comparison.

-

Select the Accuracy: Low,

Medium, or High.

-

Select

the Automatic Refresh check box to maintain the high

quality of the image after a view change.

-

Select the Transparency check box to only display gouges

or the remaining part to detect issues at the first sight of problems. Use the

slider to manage the level of transparency from 0 (no transparency) to 255 (full

transparency).

-

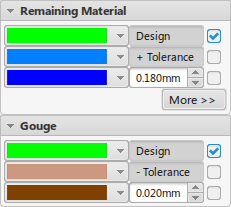

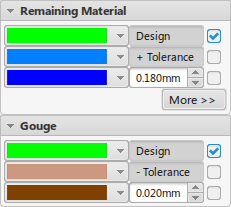

Specify the tolerance bands in the Remaining Material and

Gouge areas.

-

Click Apply.

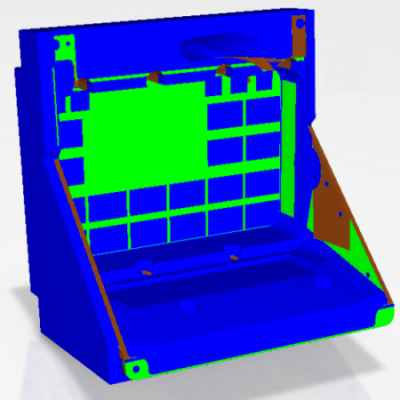

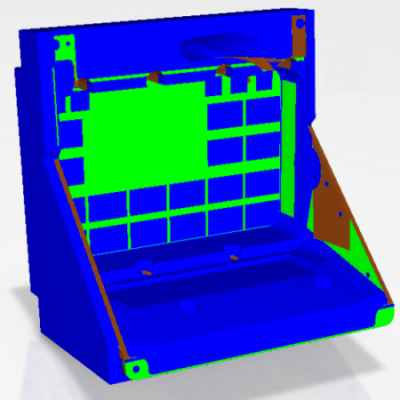

The machined stock is compared with the design part, based

on the specified options.

Notes:

- Any point on the machined stock is considered a fault if the distance (deviation) to the

design part surface is greater than the specified tolerance.

- The results of the comparison are reflected on the workpiece, based on the

severity of the fault and the configured color settings.