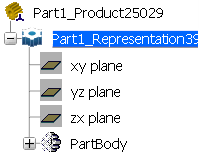

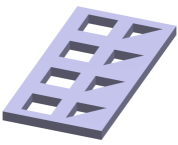

- In a product like this one,

-

Select a machining

app

then the

Programming

section.

An empty

Manufacturing

Cell is created with an

Activities Process

Tree.

-

Create a generic machine or assign a

machine from the database.

As soon as a

machine is assigned to the

Manufacturing

Cell,

a

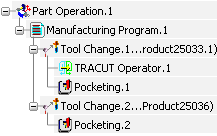

Part Operation

and a

Manufacturing Program

are created in the

Activities Process

Tree.

-

Alternatively, open an existing

Machining Process

or

PPR Context.

By default, the

Activities Process

Tree

is available.

- Create Pocketing

operation:

- Select

Prismatic Machining

section.

- Click

Pocketing and create a first Pocketing operation

on the first square cut-out. Pocketing and create a first Pocketing operation

on the first square cut-out. - Create a second Pocketing

operation using a different tool on the first triangular

cut-out.

When creating these pockets, make

sure that the Island Detection context menu menu command is not active before you select the pocket bottom.

- Right-click the Manufacturing Program

and select Compute Tool Path.

- Select

the Compute if necessary option in the pop-up

that appears.

- Select Tool Change.1 in the Manufacturing Program.

- Click

TRACUT Operator Instruction. TRACUT Operator Instruction.

A TRACUT Operator Instruction is inserted in the

Manufacturing Program before Tool Change.1 and the TRACUT Operator

dialog box appears.

- Create a

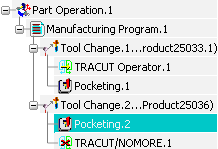

TRACUT/NOMORE Instruction:- In the dialog box, click

Create a TRACUT/NOMORE instruction.

Create a TRACUT/NOMORE instruction. - Select an activity in the Manufacturing Program to specify the insertion

level.

We have selected Pocketing.2 to insert the TRACUT/NOMORE

instruction after that operation.

The TRACUT Operator Instruction is applied to the

two Tool Changes and the two Pocketing operations.  - Still in the TRACUT Operator

dialog box, define the transformation. For example:

- Set the Transformation type

to Translation.

- Set the Translation type to Absolute

Coordinates.

- Set the Distance

along X to 100mm.

- If needed, go to the Syntax

tab

to consult the PP instruction that is applied for the TRACUT

Operator Instruction.

to consult the PP instruction that is applied for the TRACUT

Operator Instruction. - Click OK to create the TRACUT Operator Instruction in the Manufacturing Program.

- To visualize the tool path resulting

from the defined TRACUT Operator Instruction:

-

Select the first Tool Change in the Manufacturing Program and click Display or

Simulate.

-

Click

to

take the TRACUT Operator Instructions into

account to display the tool path. to

take the TRACUT Operator Instructions into

account to display the tool path.

- Replay the tool changes and Pocketing

operations.

- Close the dialog box at the end of the

replay.

|