Opening a Manufacturing

Cell Without a PPR Context

You can open a manufacturing cell independently from a PPR Context.

Before you begin:

Make sure that you have enabled the Enable PPR Context propagation in

database option in the PPR Context

tab under

.

-

Import a 3D XML file containing a PPR Context.

-

Open the manufacturing cell only without PPR Context.

-

Open one of the following machining applications:

- Prismatic Machining: Axial and Prismatic activities.

- Milling Machining: Axial, Prismatic, and Surface activities.

- Multi-Axis Machining: Axial, Prismatic, Surface, and 5x activities.

- Mill-Turn Machining: Axial, Prismatic, Surface, 5x, and Turning

activities.

- Prismatic and Turning Machining: Axial, Prismatic, and Turning

activities.

The license checking is changed and is computed with the access

rights of the machining applications.

The machining application is opened with the machining view displayed.

Managing from the Activities Process

Tree PPR Context And Manufacturing

Cell

You can manage the resources of a manufacturing process from the PPR

Context.

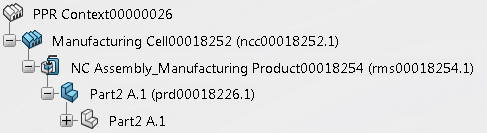

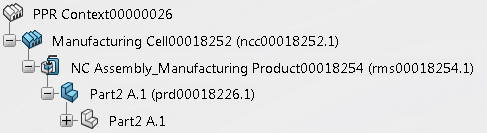

The PPR Context contains:

-

Click Content and Simulation and select the manufacturing cell

The NC Machine Programming Wizard is

displayed. A PPR Context is created in the tree. It contains a Manufacturing

Cell, that contains the part to machine.

-

Create a machine NC

Programming Wizard.

A Machining Programs_Behavior node and a

product containing the machine are added to the tree.

-

Create a tool.

A product containing the tool specifications is added to the tree.

-

Continue the same way for other resources.

-

Alternatively, right-click the PPR Context and select Insert

Resource > Existing Product or

Resource in the context menu. Follow the instructions in the

work area to insert the resource.

Search a Manufacturing

Cell in the Database and Explore in PPR

You can open a PPR Context and a Manufacturing

Cell from a Search.

-

In the Search box, enter a search string such as

prd: PPR* and click Search

. .

-

Select the PPR Context in the Search Results and

select Open in the context menu.

The PPR Context and all the related objects are retrieved from the

database and displayed in the PPR editor.

-

For a Manufacturing

Cell, enter prd:Manufacturing*.

Manage Inconsistent Links from a Machining Program Representation

This helps you how to manage inconsistent links within a Machining object.

-

Right-click Manufacturing

Cell.

-

Select Managing Inconsistent Links.

At first, this checks if some links have been automatically rerouted. If

reconnecting is available, reconnecting is performed and an information

message appears, Automatic reconnection has been successfully

performed.

The remaining broken links are displayed and sorted by machining objects

using the inconsistent links.

-

Perform a Edit or Delete:

They are enabled according to the selected line:

Edit action is available on several links:

- Link used by part operation

- Link used by machining operation

- Link used by machining feature (ex:

pattern).

It is not available for internal features (like Local parameters of

tools) and helps to perform a manual intervention by directly editing

the feature using the link.

Edit opens the usual feature edition panel (for

example, Machining Operation panel for link used by the operation).

Delete is not available for the following links:

- Link to geometry (use edit and take action from edit panel

instead)

- Link from representation to NC

machine instance.

Delete isolates the link.

It also deletes the associated feature in the following cases:

- From tool magazine to NC tools

- From machine configuration to Machine Accessories / Spindle

- From Turret axis system to turret.

-

Click X to end.

Start Machine Programming

This describes how to start Machine Programming.

-

From a product containing a part to machine:

-

Select Start > Machining > Machine Programming. A PPR Context with an empty Manufacturing

Cell is created. An empty Activities Process

Tree opens automatically.

-

Create a generic machine or assign a machine from the database. As

soon as a machine is assigned to the Manufacturing

Cell, a Part Operation and a Manufacturing Program are created

in the Activities Process

Tree.

In addition to the work area that contains a geometric view of the products, and to the Activities Process

Tree that contains the machining activities, Machine Programming creates a tree named PPRContext_Productxxx. Note:

The name may

vary according to the environment defined by your administrator.

The PPR Contextcontains:

- A resource called the Manufacturing

Cell that includes:

- One single machine,

- The tools,

- The tool assemblies,

- Accessories,

- A resource called NC Assembly

- A representation called Machining

Programs that contains the programs of

the machine. This representation is attached to one

particular machine. That is, all the Part

Operations that it contains are

associated to this particular machine, and taken into

account by the Generic Machine

dialog box. Thus changing the machine in the

Generic Machine dialog box

affects all the associated Part

Operations.

- Processes and system data optionally created by you, these

objects link resource data to the product data. They hold

implement links that are used in the PPR Navigator to analyze

impacts of engineering changes on the resource data. See Managing Design Changes and Links.

Note:

The Manufacturing

Cell is the main object for the Machine Programmer.

-

Select to save the PPR Context.

NC Assembly Definition

NC Assembly is a Resource of type Manufacturing Setup that instantiates

products containing geometric definition required for the NC programmer as the

stock, the part, and additional geometry.

Right-click the Manufacturing

Cell from the tree, select Insert then select Existing NC

Assembly, this aggregates it.

Note:

At start of machining:

- When a part is active: a new NC assembly is aggregated under

Manufacturing

Cell and the part is aggregated under it.

- When an NC assembly is active: it is aggregated under Manufacturing

Cell.

Product structure commands like insert 3Dpart, replace by version, are

available in a product structure, double-click the NC assembly.

Sending a Tool to Library

You can send tool elements to libraries.

-

Right-click a

resource and select .

The Send to Library dialog box appears.

-

To Create a New Library:

-

Make sure thatCreate a New

Library is selected.

-

Specify the Library Name and the

Class Name.

-

Click OK.

Note:

Before sending the resources to a library, ensure resources are

saved.

-

To Update an Existing Library:

-

Make sure that Update an

Existing Library is selected.

-

Select an existing Library Name from the

drop-down menu.

Note:

You can also search an existing Library

from database  . .

-

Select an existing Class Name from the

drop-down menu or select Edit to Create a New Class

Name to enter a new Class

Name.

-

If you select a Class Name from the

drop-down menu, the following options are available:

- Add selected revision: adds the

selected resource revision in existing library class. By

default, this option is checked.

- Replace revisions older than the selected

one: replaces all the older revisions of the

selected resource existing in library class by the selected

resource revision.

This name must be unique.

-

Click OK in the information message box

displayed at the end of the addition.

Note:

Before sending the resources to a library, ensure resources

are saved.

|