Creating a Multi-Axis Helix Machining Operation in Interpolation Mode | |||||

|

| ||||

- The following procedure describes how to machine the middle

(green) blade of the part shown below with no tool collisions with the two

neighboring blades.

- From the Surface Machining section of the action bar, click Multi-Axis Helix Machining

.

.

A Helix Machining entity is added to the manufacturing program. The Multi-Axis Helix Machining dialog box opens directly at the Geometry tab

.

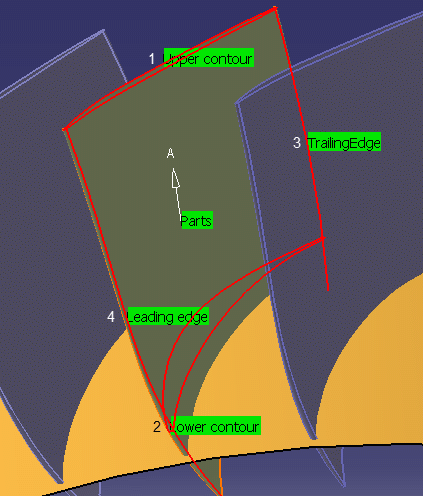

.The part surface, upper and lower contours, and leading and trailing edges of the sensitive icon are colored red indicating that this geometry is required and must be selected.

The upper and lower contours and the leading and trailing edges must lie on the faces selected as part surface. Selection of check elements (such as neighboring blades or fixtures) is optional.

- Still in the Geometry tab, click the red part surface in the icon then select the faces

to be machined in the work area.

- The Face Wizard appears to help you select these faces.

- In this scenario, you must select 4 faces: The front face, the back face, the leading face, and the trailing face.

Note: Faces must be continuous. Gaps between faces may result in a bad tool path. - Still in the Geometry tab, select the upper and lower contours.

The Edge Wizard appears to help you select these contours.

Note: They must be closed contours. - Still in the Geometry tab, select the leading and trailing edges to define the limits

of the machining.

The Edge Wizard appears to help you select these contours.

Note: They must intersect the upper and lower contours.- 1 = upper contour

- 2 = lower contour

- 3 = trailing edge

- 4 = leading edge

- The geometry entities of the icon are now colored green indicating that this geometry is now defined.

- At this stage, make sure the Collision Checking option in the Geometry tab is deactivated.

- Go to the Tools tab

to select a tool, for example a conical mill tool

with the following characteristics.

to select a tool, for example a conical mill tool

with the following characteristics. - Go to the Strategy tab

:

:- Set the Tool Axis Mode to Interpolation.

- Select a Start point by first clicking a point symbol in the sensitive icon then selecting any point on the part surface.

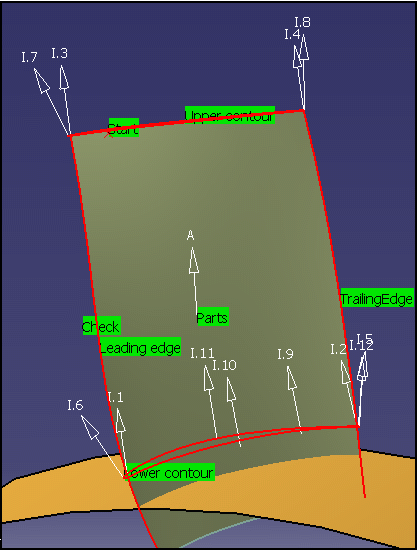

- Click one of the interpolation

axis symbols in the sensitive icon.

Default Interpolation axes (I.1 to I.4) are displayed at the four corners of the part.

The Interpolation Axes dialog box is displayed.

All the interpolation vectors are listed with their position, direction and status.

- In the Interpolation Axes dialog box:

-

Pick a vector in the dialog box.It is highlighted in the work area.

-

Click

to add an interpolation vector.

to add an interpolation vector.The Interpolation Axes dialog box disappears.

-

Pick in the work area to indicate the position of this new

interpolation vector.Its Axis Definition dialog box appears (see below).

- Click OK in the dialog boxes when you are done.

- Click

to

remove the interpolation vector selected in the dialog box.

to

remove the interpolation vector selected in the dialog box. - Click

to edit

the interpolation vector selected in the dialog box. The Axis Definition dialog box is displayed.

to edit

the interpolation vector selected in the dialog box. The Axis Definition dialog box is displayed. - Click OK in the dialog boxes when the interpolation axes are defined.

-

Pick a vector in the dialog box.

- Specify the parameters for the machining operation.

- Machining

- Direction of cut to Conventional

- Machining tolerance

- Max discretization step

- Max discretization angle

- Radial

- Stepover to Number of turns

- Number of turns

- Skip path to None

- Machining

-

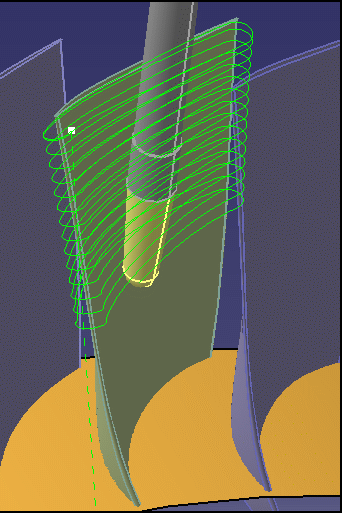

Click Display or

Simulate to check that the tool can be positioned at each point on the trajectory.

Note: See Displaying Tool Path

- If the tool cannot be positioned at each point on the trajectory, adjust the default interpolation axes and possibly insert additional interpolation axes until this criteria is satisfied.

- Add an additional axis: Click one of the interpolation axis symbols in the Strategy tab, then either select an existing point on the part or pick anywhere on the part.

-

Delete an additional axis: Right-click it and select the

Remove

context menu item.

To delete all additional axes: Right-click one of the interpolation axis symbols in the Strategy tab and select the Remove all additional axes context menu item.

Notes:- Default axes cannot be removed.

- Interpolation axes are applied at contact points on the trajectory. The application point of an interpolation axis must be on a selected face. If the point is not on a selected face, it will be projected onto the part. This may give undesirable results.

- Once the tool can be positioned at each point on the trajectory, select the collision checking option in the Geometry tab.

- If there are collisions detected, adjust the interpolation axes until the tool path is collision free.

- Once there are no collisions, select the faces of neighboring blades as check surfaces.

- Click Display or Simulate to check for collisions with the selected faces.

- If necessary, adjust the interpolation axes and possibly

insert additional interpolation axes until the tool path is collision free.

The following figure shows an example of the default and additional interpolation axes that will give a collision-free trajectory.

The corresponding data is as follows:

Axis

Application point coordinates

Interpolation axis vectors

1

Intersection point

u=0.224917 v=0.0174524 w=0.974222

2

Intersection point

u=0.292194 v=-0.0348995 w=0.955722

3

Intersection point

u=0.15643 v=0 w=0.987688

4

Intersection point

u=0.308264 v=0.0697565 w=0.94874

5

x=-20.8009 y=18.814 z=192.1

u=-0.0688977 v=0.156434 w=0.985282

6

x=23.0488 y=-11.0264 z=192.676

u=0.103351 v=-0.529919 w=0.841727

7

x=12.9556 y=-22.0174 z=252

u=0 v=-0.45399 w=0.891007

8

x=-10.2918 y=16.9498 z=252

u=-0.069714 v=0.0348995 w=0.996956

9

x=-14.1239 y=9.91563 z=192.142

u=0.25878 v=-0.0174524 w=0.965779

10

x=-4.66894 y=1.32628 z=191.888

u=0.207785 v=-0.0348995 w=0.977552

11

x=-5.69227 y=-3.93598 z=192.877

u=0.0347667 v=-0.0871557 w=0.995588

12

x=-20.6779 y=19.1817 z=191.995

u=0.137059 v=0.173648 w=0.975224

-

Click Display or

Simulate to check for collisions.

- Click OK to create the machining operation.