About APT Output | ||

| ||

A automated drill and rivet machine is composed of head and an anvil. At each rivet origin, a specific sequence needs to be simulated.

The main inputs of the operation are:

- A mfg pattern owning a sequence of mfg fasteners

- Several instruction sets describing the sequence of motions to be simulated before and after each rivet origin

- Macro motions describing the Cartesian motions of the machine head between the rivet origins.

A typical drilling riveting operation allows the following:

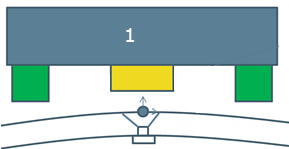

- Move the machine head following approach

macro motion

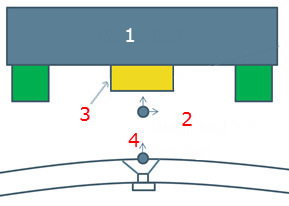

1 - Machine head

2 - Machine head TCP (0,0,520)

3- Pressure foot (Pressure foot to Machine head 5.000)

4- Rivet origin (0,0,500) Rivet origin to part 6.000)

- Apply Entry instruction set (typically to move the anvil at working position). This would involve an instruction set with the following motion action defined (Assuming that the anvil is mounted on the Z Axis of the machine) Z Axis, Absolute, +, 490.000000 mm , 2000 mmpm => Motion Action

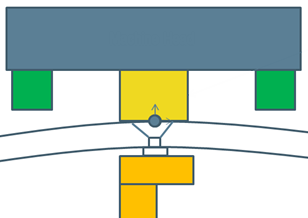

- Move the machine head up to the first rivet origin (defined by mfg fastener).

- Apply Exit instruction set (typically to move the anvil and the pressure foot). This involves an instruction set with the following actions defined (Assuming that the anvil is mounted on the Z Axis of the machine and Pressure foot is mounted on the A axis of the machine).

Z Axis, Relative, +, 4.000000 mm , 2000 mmpm A Axis, Relative, - , 5.000000 mm , 2000 mmpm Dwell, 5 s A Axis, Relative, +, 5.000000 mm , 2000 mmpm Z Axis, Relative, -, 4.000000 mm , 2000 mmpm

This example, there is Motion Action1, Dwell Action then Motion Action 2.

- Retract the machine head following retract macro motion.

Results:

| $$ OPERATION NAME : Drilling Riveting.1 | ||

| $$ Start generation of : Drilling Riveting.1 | ||

| PPRINT NC_DR_MO_START_COMMENT BEGIN | NC_DR_MO_START_COMMENT | |

| PPRINT MACHINE OPERATION = Drilling Riveting | ||

| PPRINT OPERATION NAME = Drilling Riveting.1 | ||

| PPRINT NC_DR_MO_START_COMMENT END | ||

| PPRINT NC_INSTRUCTIONSET_START | NC_INSTRUCTIONSET_START | Entry Instruction Set |

| PPRINT NC_INSTRUCTIONSET_MOVE_START | NC_INSTRUCTIONSET_MOVE_START | |

| PPRINT DEVICEMOVE_START = MachineXYZ | NC_INSTRUCTIONSET_DEVICEMOVE_START | |

| INST_FED/2000,MMPM | NC_INSTRUCTIONSET_AXIS_FEEDRATE | |

| MOVE/Z,ABS,490.000000 | NC_INSTRUCTIONSET_AXIS_MOVE | |

| PPRINT NC_INST_DEVICEMOVE_START = MachineXYZ | NC_INSTRUCTIONSET_DEVICEMOVE_END | |

| PPRINT NC_INSTRUCTIONSET_MOVE_END | NC_INSTRUCTIONSET_MOVE_END | |

| PPRINT NC_INSTRUCTIONSET_END | NC_INSTRUCTIONSET_END | |

| FEDRAT/60000.0000,MMPM | Goto rivet Origin | |

| GOTO / 0.0000, 0.0000, 500.0000 | ||

| PPRINT NC_INSTRUCTIONSET_START | NC_INSTRUCTIONSET_START | Exit Instruction Set |

| PPRINT NC_INSTRUCTIONSET_MOVE_START | NC_INSTRUCTIONSET_MOVE_START | |

| PPRINT NC_INST_DEVICEMOVE_START = MachineXYZ | NC_INSTRUCTIONSET_DEVICEMOVE_START | |

| INST_FED/2000,MMPM | NC_INSTRUCTIONSET_AXIS_FEEDRATE | |

| MOVE/Z,INCR,4.000000 | NC_INSTRUCTIONSET_AXIS_MOVE | |

| INST_FED/2000,MMPM | NC_INSTRUCTIONSET_AXIS_FEEDRATE | |

| MOVE/A,INCR,-5.000000 | NC_INSTRUCTIONSET_AXIS_MOVE | |

| PPRINT DEVICEMOVE_END = MachineXYZ | NC_INSTRUCTIONSET_DEVICEMOVE_END | |

| PPRINT NC_INSTRUCTIONSET_MOVE_END | NC_INSTRUCTIONSET_MOVE_END | |

| DELAY/5s | NC_INSTRUCTIONSET_DWELL | |

| PPRINT NC_INSTRUCTIONSET_MOVE_START | NC_INSTRUCTIONSET_MOVE_START | |

| PPRINT NC_INST_DEVICEMOVE_START = MachineXYZ | NC_INSTRUCTIONSET_DEVICEMOVE_START | |

| INST_FED/2000,MMPM | NC_INSTRUCTIONSET_AXIS_FEEDRATE | |

| MOVE/A,INCR,5.000000 | NC_INSTRUCTIONSET_AXIS_MOVE | |

| INST_FED/2000,MMPM | NC_INSTRUCTIONSET_AXIS_FEEDRATE | |

| MOVE/Z,INCR,-4.000000 | NC_INSTRUCTIONSET_AXIS_MOVE | |

| PPRINT NC_INST_DEVICEMOVE_START = MachineXYZ | NC_INSTRUCTIONSET_DEVICEMOVE_END | |

| PPRINT NC_INSTRUCTIONSET_MOVE_END | NC_INSTRUCTIONSET_MOVE_END | |

| PPRINT NC_INSTRUCTIONSET_END | NC_INSTRUCTIONSET_END | |

| FEDRAT/60000.0000,MMPM | Retract Motion | |

| GOTO / 0.0000, 0.0000, 750.0000 | ||

| PPRINT NC_DR_MO_END_COMMENT BEGIN | NC_DR_MO_START_COMMENT | |

| PPRINT MACHINE OPERATION = Drilling Riveting | ||

| PPRINT OPERATION NAME = Drilling Riveting.1 | ||

| PPRINT NC_DR_MO_END_COMMENT END | ||

| $$ End generation of : Drilling Riveting.1 | ||

Note:

Lateral direction information available for the Cartesian points in the drilling and riveting operation is generated in the APT output as follows:

GOTO / X, Y, Z, I, J, K, U, V, W where U,V and W are the components of the lateral direction at the particular Cartesian point.