About Drilling and Riveting Processes | ||||

|

| |||

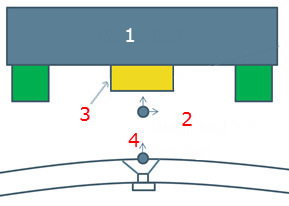

An automated Drill and Rivet machine is composed of head and an anvil. At each rivet origin, a specific sequence needs to be simulated.

The main inputs of the operation are:

- A manufacturing pattern owning a sequence of manufacturing fasteners.

- Several instruction sets describing the sequence of motions to be simulated before and after each rivet origin.

- Macro motions describing the Cartesian motions of the machine head between the rivet origins.

A typical Drilling Riveting operation allows the following:

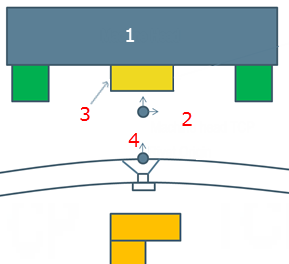

- Move the machine head following approach

macro motion

1 - Machine head

2 - Machine head TCP

3- Pressure foot

4- Rivet origin

- Apply approach instruction set (typically to move the anvil at working position)

- Move the machine head up to the first rivet origin (defined by manufacturing fastener)

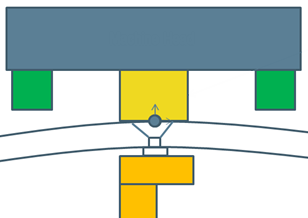

- Apply fastening instruction set (typically to move the anvil and the pressure foot)

- Move the machine head to the position of next manufacturing fastener (following linking and clearance macro motions). Apply the approach and fastening instruction sets.

- Retract the machine head following retract macro motion.

Right-clicking on a fastener point gives access to contextual commands. See Context Menus.