Creating and Using Prismatic Machining Areas with the Legacy User Interface

-

Activate

the Manufacturing Program and click Prismatic

Machining Area

in the

Prismatic Machining section of the action bar.

The Prismatic Machining Area dialog box includes a sensitive icon to help you specify the geometry. Areas of the icon are colored red indicating that this geometry is required.

in the

Prismatic Machining section of the action bar.

The Prismatic Machining Area dialog box includes a sensitive icon to help you specify the geometry. Areas of the icon are colored red indicating that this geometry is required. -

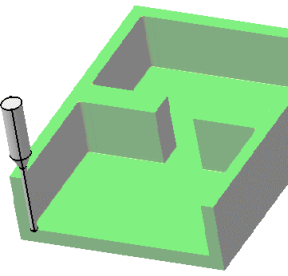

Click the red Bottom in the sensitive

icon then select the pocket bottom in the work area.

The pocket boundary (Guide.1) is automatically deduced from the pocket bottom.

-

Click OK to create the feature called Prismatic

machining area.1.

This feature references the selected pocket geometry.

-

Make a machining activity current in the Activities tree, then

click Pocketing

in the

Prismatic Machining section of the action bar.

in the

Prismatic Machining section of the action bar.

-

Select Prismatic machining area.1 in the

Feature list, in the Pocketing dialog

box.

The operation geometry shows the elements referenced by the feature (pocket bottom, guide, and so on).

Note: Any modification to this geometry in the operation also modifies the geometry of the feature. However, if the feature is used by another operation, it is impossible to modify its geometry in the machining operation editor. -

Go to the Tool tab

to select a tool, in the Pocketing dialog box.

to select a tool, in the Pocketing dialog box.

-

Go to the Macros tab

to specify a

Retract macro with a linear retract path of 50mm.

to specify a

Retract macro with a linear retract path of 50mm.

-

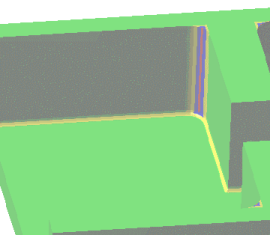

Simulate the tool path to verify the

Pocketing operation.

The pocketing operation leaves some unmachined material in the corners.

- Click OK to create the Pocketing operation.

-

Select Prismatic machining area.1 in the

Feature list, in the Pocketing dialog

box.

-

Click Profile Contouring

in the

Prismatic Machining section of the action bar.

in the

Prismatic Machining section of the action bar.

-

In the Profile Contouring dialog box, select

Prismatic machining area.1 in the Feature

list.

The operation geometry is initialized with the pocket bottom and guide elements referenced by the feature.

- Select a tool with a 5mm nominal diameter.

-

Select the Macros tab

to specify an

Approach macro with a linear approach path of 50mm.

to specify an

Approach macro with a linear approach path of 50mm.

-

Simulate the tool path to verify the Profile Contouring

operation.

- Click OK to create the Profile Contouring operation.

-

In the Profile Contouring dialog box, select

Prismatic machining area.1 in the Feature

list.

-

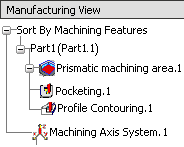

Click Manufacturing View

to display the

Manufacturing View.

to display the

Manufacturing View.

In the context menu, select the Sort by Machining Features item to see how the Prismatic machining area is referenced by the Pocketing and Profile Contouring operations.

Notes:- The tool entry direction for a Prismatic machining area is the normal to the selected bottom. When the same Prismatic machining area is used in another operation, the tool axis takes precedence and the computation is done based on the tool axis.

- In addition to Pocketing and Profile Contouring operations, Prismatic Machining Areas can also be used for Creating a Prismatic Rework Area for Corners and Channels.

- It is impossible to reuse a Prismatic Machining Area created in a machining operation. To reuse a Prismatic Machining Area, create the area using Global Feature Recognition, Local Feature Recognition, or Prismatic Machining Area commands.