Synchronizing a Spot Weld Task | |||||

|

| ||||

-

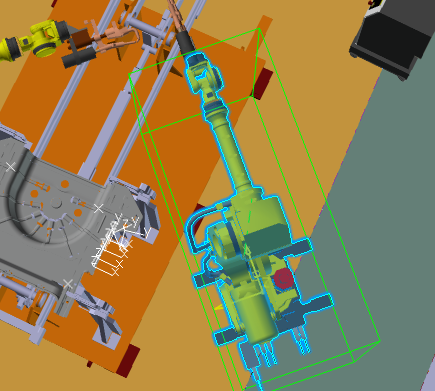

In the work area,

select a robot as the Active Simulation Object.

-

In the Tools section of the action bar,

click B.I. Essentials

.

The B.I. Essentials panel appears.

.

The B.I. Essentials panel appears. -

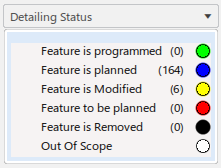

In the B.I. Essentials panel, select Detailing

Status from the list.

The Detailing Status legend is displayed.

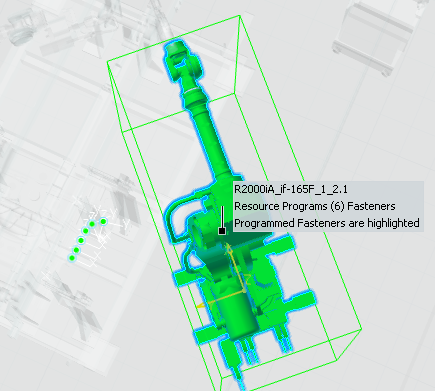

Tip: You can select a row in the dialog box to highlight the corresponding fasteners in the work area. The fasteners associated with the selected robot are highlighted and colored according to their detailing status.

In the example above, six fasteners are highlighted in yellow (Feature is Modified), indicating that they have been modified and are not synchronized with the current manufacturing data.

-

In the Point Fastening section of the action bar,

click Update Spot Task

.

.

Alternatively, you can right-click the Spot task in the Behavior side tab and select Update from the context menu

If the associated Spot Dress Up trajectory is not up-to-date with respect to first and last manufacturing welds in the trajectory, a message is displayed to indicate that the Approach/Departure tags are not up-to-date with respect to first/last Spot Weld:

- Click Yes to proceed with the update.

A message displays the results of the update.

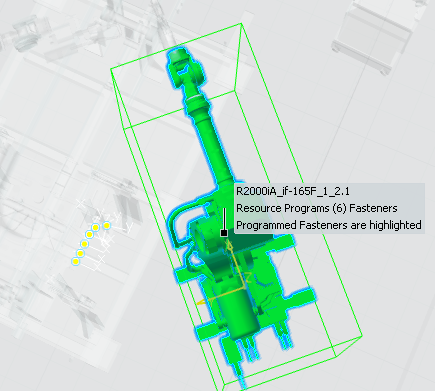

The fasteners have been updated and are now highlighted in green (Feature is Programmed), as shown below.