Navigate Through Drilled Cooling Circuit

You can work at several levels in Drilled Cooling Circuit.

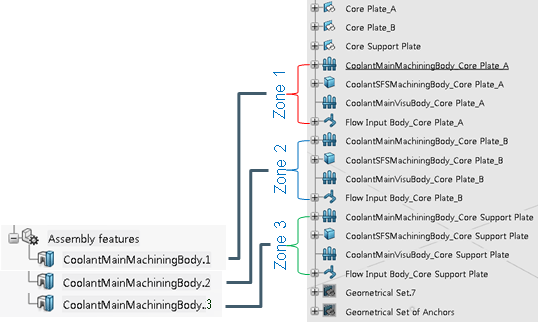

- Create Cooling Zones.

One is created as you enter Drilled Cooling Circuit. You can add as many as required.

See Create Cooling Zones.

-

Back in the dialog box, go to Drilled Cooling Circuit

Preferences

and specify the default

values used globally.

and specify the default

values used globally.

See Set the Diameter of the Drilled Cooling Circuits, Select the Type of the Drill Hole and Add a Tap Hole.

- In the main panel of the dialog box:

- Define the Scope.

- Whole zone to work on all the Cooling Channels of the current zone (defined by your first pick).

- Selected to work on Cooling Channels you have selected, possibly from different zones.

Parameters are displayed according to selection. - Define the Scope.

- Modify the parameters locally.

- In case of multiselection, click Apply current parameters to selection.

- To edit the value of a parameter defined by a protected formula, clear Respect User Formula and enter a value.

Edition of the formula is not available.

- In the context toolbar, create or edit elements.