Item Editor

The item editor provides tools for defining and editing Manufacturing Assemblies.

The editor comprises of the following elements:

- A grid on which you can build an item flow represented

by tiles in a graph

- A tree

- A group of commands enabling you to insert items,

manage the grid layout, and so on.

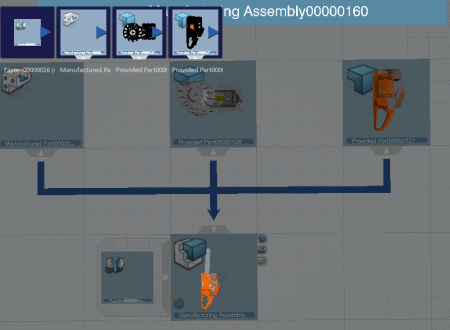

The

item representations in the graph are known as predecessors (that is, child items) and successors (that is, parent items). Items are

connected by data requirement links and precedence constraints, and this represents the item

flow.

A data requirement link goes from the output of a predecessor to the

input of its successor. A precedence constraint connects two sibling

items on the same level.

By default, data requirement links appear in blue and precedence

constraints appear in orange. You can customize Connection colors in

. By default, data requirement links appear in blue and precedence

constraints appear in orange. You can customize Connection colors in

.

Tile Description

Tabs on Tiles and Context Toolbar

Tabs on tiles and a context toolbar are provided in the item editor for analyzing the

Manufacturing Assembly structure, identifying which predecessors are used, and rerouting items.

Contextual Commands for Expand/Collapse and Hide/Show

Contextual commands to expand and collapse the graph, and to hide or show

Provided Parts, Manufactured Parts, and Fasten steps are available. For more information, see Managing the Tiles in the Graph.

Contextual Commands for Rerouting

Contextual commands to reroute items that have inputs (such as Manufacturing Installation, and Transform) are available. For more information, see Rerouting Items.

Item-Product

Scope Management

You can manage Item-Product scopes in the item editor.

The Item-Product scope delimits a subset of the product structure that can be implemented by an

item. For example, this enables product structure subsets to be isolated and

assigned to different system planners. The scope is defined by an implement link from a reference item to a reference

product. For more information, see Item-Product Scope.

In the item editor, you can:

- Define the scope between an item and a product using the Create

Item-Product Scope contextual command. In this case, the Item-Product scope

icon appears on the tile icon appears on the tile

- Delete the scope between an item and a product using the Remove

Item-Product Scope

contextual command. contextual command.

Note:

A scope between an item and a system can be defined in Process Planning

app. In this case, the System-Item scope  icon appears on the tile. icon appears on the tile.

Item Management

A number of capabilities are available for managing items in the item editor.

Capabilities include:

- Insert Predecessor context menu on tile.

- Insert Predecessor context menu in the tree.

- Drag and drop to modify data requirement links.

Selecting Products

Products can be selected using the 3D view in the item editor, Smart

Zoom, and tree.

Smart Zoom Capability

The Smart Zoom capability is useful for investigating the 3D

representation and for selecting and assigning products. It can be activated at

any time by pressing F6. The 3D representation becomes

detached from the tile and then it can be rotated and zoomed. Note:

Press

F6 again to exit the Smart

Zoom.

Digger Functionality in Smart Zoom

The digger functionality is available when Smart Zoom is

active. It is used to temporarily disable geometry that hides other parts of 3D.

Move the mouse cursor onto the outer geometry and press

F7. The hiding geometry becomes transparent and the

hidden geometry can be selected or also made transparent. Press

F8 to make the geometry visible again. For more

information, see Using

Digger.

Thumbnail Navigation in Smart Zoom

In Smart Zoom mode, you can click a left-hand or right-hand thumbnail

to change to a predecessor or successor in the graph.

Show Unassigned Parts Using Smart Zoom and the

B.I.

Essentials

Panel

In Smart Zoom mode, when Product Assignment

Status is clicked in the B.I.

Essentials panel, two contextual commands enable you

to display either the unassigned parts or all the parts.

Right-click

an empty area, then click Show Only Unassigned Parts to

display the 3D representation with only the unassigned parts.

Right-click an empty

area, then click Show All Parts to display all the parts

again.

You can navigate to a predecessor or a successor using the thumbnails. To do this, quit and

relaunch the Smart Zoom. Note:

The Show All

Parts, or Show Only Unassigned Parts

display mode is kept.

Product to Item Assignments

A product can be assigned to an item using a variety of methods such as Drag

and Drop, Smart Zoom, and assignment

assistant.

When a product is assigned to a Manufacturing Assembly, a Provided Part is created with an implement link to the assigned product.

For more information, see:

Assign Products Using Drag and Drop

It is possible to drag a product, a part, and a fastener from the tree to a tile

or another node in the tree. The rules are as follows:

- When you drag a tile or element from the tree to the border of the

viewer, the grid automatically pans in the direction of the mouse

cursor.

- The implemented parts and fasteners can be displayed in a list by

pressing F5. For more

information, see Use the F5 List to Show and Reassign Objects.

- When items implement products, parts, and fasteners that have 3D

information, they are shown on top of the item tiles.

- Parts that are displayed on top of item tiles can also be dragged

directly from these tiles to other item tiles.

- When you drag an object, the grid automatically centers on the selected

object.

The following table summarizes the behavior for dragging and dropping a product

onto a Manufacturing Assembly: Notes:

- If the product is already assigned to at least one item in the

session, a dialog box appears asking whether or not you want to

assign the product again.

- If the product is not declared as

Manufacturable/Procurable, the system asks for a

confirmation to assign it.

| Product implemented by a single object |

Product implemented by multiple objects |

Drag and drop pressing

Ctrl |

|

The implemented Manufactured Part is rerouted under the target Manufacturing Assembly.

|

A dialog box appears to indicate that there is already an

implement link and requires confirmation before creating

a new one.

If you click OK, a new Manufactured Part is created under the target Manufacturing Assembly.

The Part is assigned to the created Manufactured Part.

|

A new Manufactured Part is created under the target Manufacturing Assembly.

The Part is assigned to the created Manufactured Part.

|

The following table summarizes the behavior for dragging and dropping a part onto

a Manufactured Part: Note:

If the part is not declared as Manufacturable/Procurable,

the system asks for a confirmation to assign it.

| Part implemented by a single object |

Part implemented by multiple objects |

Drag and drop pressing

Ctrl |

|

The Part is assigned to the target Manufactured Part.

|

The Part is assigned to the target Manufactured Part.

|

The Part is assigned to the target Manufactured Part.

|

The following table summarizes the behavior for dragging and dropping a product

onto a Provided Part: Notes:

- If the product is already assigned to at least one item in the

session, a dialog box appears asking whether or not you want to

assign the product again.

- If the product is not declared as

Manufacturable/Procurable, the system asks for a

confirmation to assign it.

| Product implemented by a single object |

Product implemented by multiple objects |

Drag and drop used with

Ctrl |

|

The previous implemented link is deleted and a new link

is created.

|

A dialog box appears to indicate that there is already an

implement link and requires confirmation before creating

a new one.

If you click OK, the product is

assigned to the target Provided Part.

|

The product is assigned to the target Provided Part.

|

Note:

When Spot Fastener Assembly or Single is dragged and dropped onto a Manufacturing Assembly, a Fasten step is created to implement it. Sometimes a product is dragged and dropped

onto a Manufacturing Assembly and it is already assigned to a Manufacturing Assembly in the session. In this case, the implemented Manufacturing Assembly is rerouted under the target Manufacturing Assembly.

Assign/Unassign Parts Using Smart Zoom When parts and fasteners that are displayed as unassigned, you can assign them to the current item by double-clicking them in Smart Zoom mode or by using the Assign Part to Current Item contextual command. For example, in the Smart Zoom mode, if you select an unassigned part, then

assign it to the current item using the contextual command. The part is no

longer displayed. When you exit the Smart Zoom mode by pressing F6, the assigned part is visible on the tile. Note:

If the object is not declared as Manufacturable/Procurable, it is not proposed as an assignable product and is displayed in transparency.

Assign Product to Item Command

The

Assign Product to Item

command in the Authoring section

of the action bar enables assigning a product to a selected item. The product is then displayed

on the tile. command in the Authoring section

of the action bar enables assigning a product to a selected item. The product is then displayed

on the tile.

If a product is already assigned to at least one item in the session, a dialog

box appears asking whether or not you want to assign the product again. Note:

The

3D localization part of a bead fastener cannot be selected, so this part

cannot be assigned to an item.

If the product is not declared as Manufacturable/Procurable, the

system asks for a confirmation to assign it.

Unassign Product from Item Command The

Unassign Product from Item

command in the Authoring section

of the action bar enables unassigning a product from an item directly in the item editor or in

Smart Zoom mode. This command is available for all item

types except Manufacturing Assembly and Manufactured Part. command in the Authoring section

of the action bar enables unassigning a product from an item directly in the item editor or in

Smart Zoom mode. This command is available for all item

types except Manufacturing Assembly and Manufactured Part. Show Assigned Items Only Command The Show

Assigned Items Only

command in the Authoring section

of the action bar shows in the 3D view only those items that are related to the item, and hides

others. This command is available for a Manufacturing Assembly only. command in the Authoring section

of the action bar shows in the 3D view only those items that are related to the item, and hides

others. This command is available for a Manufacturing Assembly only. Implementation Management for Multi-Instantiated Products

For item types that implement products, it is possible to reuse an existing item reference when multi-instantiated products

are implemented. This is available for all product-to-item assignments:

Drag and Drop, Assign Product to

Item

command, Smart Zoom, Assignment

Assistant, Create/Update commands, and F5 list. command, Smart Zoom, Assignment

Assistant, Create/Update commands, and F5 list.

For implemented products, the Use same item

reference to implement multi-instantiated parts

option must be selected in

.

Cross Highlighting Between Item Editor and Tree

The cross highlighting capability enables objects to be

highlighted simultaneously in both the item editor and the tree.

For example, if an item tile is selected, the tile and the corresponding node in the tree are

highlighted.

Management of PPR Editor Views

The item editor, system editor, and 3D view can be

displayed as independent widgets of the same tab.

App Transition

Transition to an app that uses a system editor opens a system

editor widget. This is the only widget for this type of DELMIA app.

Transition to an app that uses an item editor opens an item

editor widget. This is the only widget for this type of DELMIA app.

Opening a PPR Structure in Different Widgets

When you open a PPR structure, the structure is opened in the

widget corresponding to the last compatible app.

For example, if Manufactured Item Definition was the last compatible app opened, the PPR structure opens in an item editor widget.

Then, if you start Process Planning, the structure opens in a system editor widget in the same tab.

Finally, if you start Planning Structure, the structure opens in a 3D view widget in the same tab.

App Transition for Apps with Same Type of Grid

If you switch from one DELMIA app to another that has the same widget type, you change app.

For example, you can switch from Manufactured Item Definition to Fastened Item Definition. In this case, the item editor widget stays open but the current app is now Fastened Item Definition. As shown by the app name in the window header and the commands in the action bar.

Special Transition

Special transition is a quick way to open a structure in a

specific app.

For example, search and then select a structure you want to

open. Then, you can select the app where you want to open the structure from the list of apps. The structure opens in the selected app.

New Content

If you select a new system or workplan from the New Content panel, by

default the system opens in a system editor widget. However, if the last opened

widget was a 3D view widget, the system opens in a 3D view widget.

If you select a new item from the New Content panel, by

default the item opens in an item editor widget. However, if the last opened

widget was a 3D view widget, the item opens in a 3D view widget.

|

![]() By default, data requirement links appear in blue and precedence

constraints appear in orange. You can customize Connection colors in

.

By default, data requirement links appear in blue and precedence

constraints appear in orange. You can customize Connection colors in

.

: appears if the

: appears if the  : appears in the upper right if a resource

is associated with the item.

: appears in the upper right if a resource

is associated with the item. and down

and down  arrow commands are displayed at the input and output of a tile. These

commands enable you to expand or collapse the graph to show predecessors or

successors.

arrow commands are displayed at the input and output of a tile. These

commands enable you to expand or collapse the graph to show predecessors or

successors.