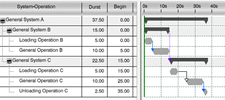

The

value added is an optional attribute that can be

specified on each operation of the system. This value is shown for each

operation, and the average value of all operations is shown for the system.

Value added of an operation is an estimate of

how much time that the operation is used for assembly. It is expressed as a

percentage. If no time of the operation is spent on assembly, the

value added can be specified as 0%.

Value added can be used on an operation that

has its time mode defined as Estimated time or Analyzed time. For

value added based on Estimated time, the value

is defined in the operation's

Properties dialog box. For

value added based on Analyzed time, the value is

defined using

Edit Time Analysis. See the

Time-Motion Study

User's Guide for more information.

Sometimes operations have time modes defined as Simulated time or Work

instruction. In this case, the

value added is the percentage defined in

Value Added Ratio on Estimated Time in the

Properties dialog box.

Note:

This information is only displayed in the Gantt chart when the Display value

added ration on system option is selected in

.

You can display a value added categories bar on top of the system cycle

bar. The value added categories are defined on the time

analysis of an operation. You can specify the color of each category in

(for example, green for value added, red for

nonvalue added, and so on). The total value for each

category is computed for all the operations in the system.

Note:

This information is

only displayed when the Display value added categories from Time

Analysis on system option is selected in the

.