The material properties reported by Famiglietti and Prevost are used in this

example.

A Young's modulus of 2.25 and a Poisson's ratio of 0.125 define the elastic

response of the concrete. A density of

0.1 is used.

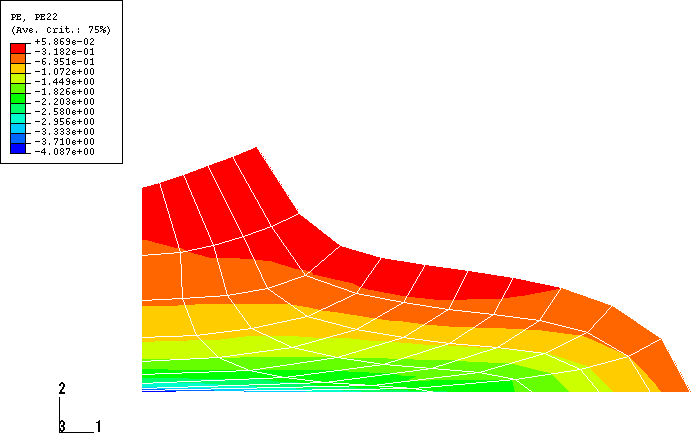

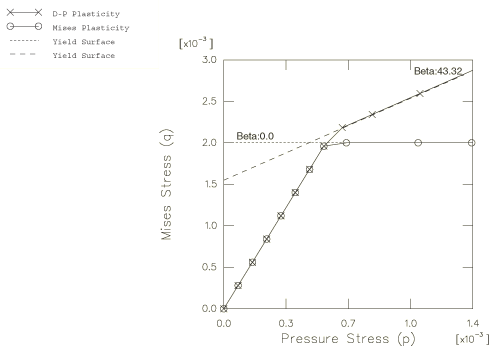

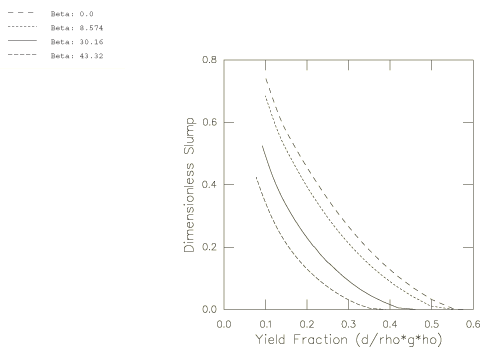

It is assumed that the inelastic behavior is governed by the cohesion or

shear strength and by the friction angle of the material. A cohesion of

0.0011547 is used, and the responses at four different friction angles

(

0°, 5°, 20°, and 35°) are compared. Perfect plasticity is assumed. Since these

parameters are provided for a Mohr-Coulomb plasticity model, they must be

converted to linear Drucker-Prager parameters.

Extended Drucker-Prager Models

describes a method for converting Mohr-Coulomb parameters to equivalent linear

Drucker-Prager parameters. Plane strain deformation and an associated plastic

flow rule, where the dilation angle

is equal to the material friction angle ,

are assumed for the purpose of this conversion. The corresponding linear

Drucker-Prager parameters,

and d, are given in

Table 1.

The values are obtained using the expressions given in

Extended Drucker-Prager Models.

Reducing the hyperbolic yield function into a linear form requires that

Reducing the exponent yield function into a linear form requires that

1.0 and that

()−1.

The material parameters for the exponential and hyperbolic yield criteria that

create equivalent linear models are given in

Table 1.

Neither the hyperbolic nor the exponential yield criteria can be reduced to a

linear model where

0° (Mises yield surface).

The hyperbolic and exponential yield criteria both use a hyperbolic flow

potential in the meridional stress plane. This flow potential, which is

continuous and smooth, ensures that the flow direction is well-defined. The

function asymptotically approaches the straight-line Drucker-Prager flow

potential at high confining pressure stress but intersects the hydrostatic

pressure axis at an angle of 90°. This function is, therefore, preferred as a

flow potential for the Drucker-Prager model over the straight-line potential,

which has a vertex on the hydrostatic pressure axis.

To match the hyperbolic flow potential as closely as possible to the

straight-line Drucker-Prager flow potential, the parameter

must be set to a small value. The default value for the exponent model,

0.1, is assumed in this example. This value ensures that the results obtained

with this model will not deviate substantially from an equivalent straight-line

flow potential, except for a small region in the meridional plane around the

triaxial extension point. The size of this region diminishes as

decreases. This parameter rarely needs to be modified for problems where a

linear flow potential is desired for modeling the inelastic deformation.

Reducing

to a smaller value may cause convergence problems.

The inelastic material properties are specified using the extended

Drucker-Prager plasticity model with hardening.