As the strains are so large, the results should compare very closely with

the exact, rigid-plastic solution of Prager and Hodge (1951). That exact

solution gives the stresses as follows:

where k is the yield stress in pure shear

(

times the yield stress in pure tension); a0 is

the initial inside radius; b0 is the initial

outside radius; r0 is the radius, in the

initial configuration, of the material point at which the stresses are being

calculated; and

is the current value of the inside radius. The form of the solution shows that

we need only compare the radial stress, since the other stresses are obtained

directly from that component.

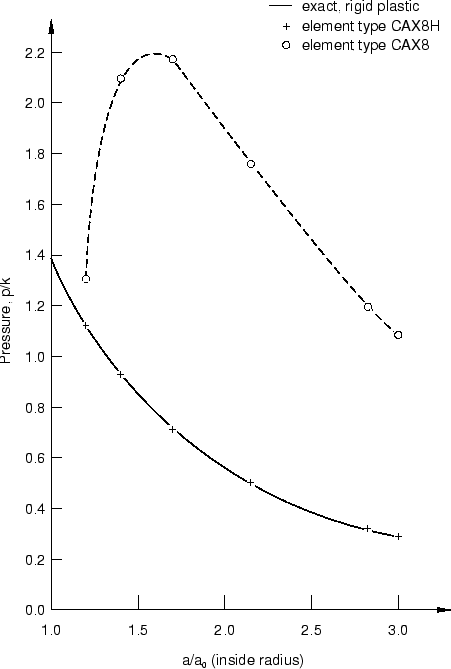

The results for the axisymmetric element models are summarized in

Figure 2

and

Figure 3,

while

Figure 4

and

Figure 5

show the results for the plane strain models.

Figure 2

compares the pressure versus inside radius given by the CAX8H and CAX8 finite element models to that given by the exact, rigid-plastic

solution. All of the axisymmetric models agree very closely with the exact

solution with the exception of that using the fully integrated 8-node (CAX8) element. Recall that the solution is obtained by prescribing the

motion of the inside surface of the cylinder, so the pressure is calculated for

the finite element models from the reaction forces conjugate to these

prescribed displacements.

Figure 3

compares the stress calculated by

Abaqus

at the point initially halfway through the cylinder wall

(

1.5) to the exact, rigid-plastic solution. Again, with the exception of the CAX8 element model, there is excellent agreement with the analytical

solution.

Figure 4

and

Figure 5

show similar results to

Figure 2

and

Figure 3

for the plane strain models. Again, with the exception of the fully integrated

8-node (CPE8) element model, all of the plane strain models show excellent

agreement with the exact, rigid-plastic solution.

The pure displacement 8-node elements (CAX8 and CPE8) give poor results because the strains are calculated directly

from the interpolation functions at each integration point, and the

incompressibility requirement causes a severe oscillation in the mean pressure

stress throughout each element. However, in the hybrid, 8-node elements the

mean pressure stress is interpolated independently, so an accurate value is

obtained for this variable. In addition, the 4-node elements in

Abaqus

are constant strain/stress elements for this case (because these elements are

coded with a constant hoop strain value and use “selective reduced

integration,” in which the volume strain is computed at the centroid only), and

so also provide accurate pressure stress values.

Results for models using the fully integrated versions of axisymmetric and

plane strain elements are shown here to caution the user. With rare exceptions

the fully integrated 8-node quadrilaterals are not as effective as the reduced

integration versions of the same elements; the reduced integration 8-node

quadrilaterals are, hence, almost always recommended over their fully

integrated counterparts. This particular problem gives a dramatic illustration

of a difficulty encountered with full integration in a problem in which the

bulk behavior of the material is very much stiffer than the shear behavior, a

type of behavior commonly encountered.