ProductsAbaqus/StandardAbaqus/Aqua

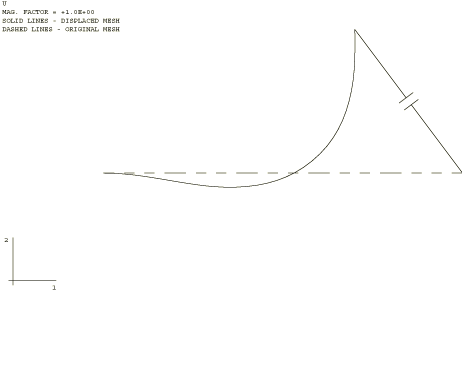

In the “near-bottom bending” approach chains, typically 5–10 m (20–30 ft)

long, are attached to the pipeline at intervals along its length. Their weight

then balances the buoyancy devices, which are attached to the pipeline, when

the pipeline is lowered to a position about 3 m (10 ft) from the seabed. The

pipeline is then winched into position at each end, with the lengths of chain

lying on the seabed acting as restraints on the motion and, thus, providing

some control over the process. One of the analyses in this example is the

prediction of configuration and stress in the pipeline throughout such a

“pull-in” process, the usual concern being to accomplish a satisfactory final

configuration without buckling or overstressing the pipeline at any time during

the installation. As a second near-bottom pipeline installation example, the

cable is assumed to remain constant in length and motion is prescribed on the

unattached end, thereby simulating a towing process.

During the pull-in or towing process the chains typically take the

configuration shown in

Figure 1:

a catenary between the attachment point and the seabed, with some length along

the seabed (this part of the chain may not lie in a straight line along the

seabed: its configuration depends on the previous motion). In

Abaqus

this is idealized as a single anchor block on the seabed, connected to the

attachment point by a catenary (Figure 2).

When two-dimensional drag chains are used, the model requires the specification

of two parameters: the horizontal distance, ,

between the attachment point and the anchor block when the system is slipping

(that is, the maximum possible horizontal distance between these points, since

the horizontal force is limited by friction) and this maximum frictional force.

Typically,

is chosen as the horizontal distance between the attachment point and a point

halfway along the horizontal chain lying on the seabed, while the maximum

frictional force is ,

where

is the friction coefficient, w is the weight of the chain

per unit length (in water), and

is the length of chain on the seabed in the actual configuration. The

three-dimensional drag chains can also be used. In this case the model requires

the specification of three parameters: the total length of the chain, the

friction coefficient, and the weight per unit length of chain. The total length

of the chain is the sum of the length of the chain on the seabed and the

suspended length. In addition, for three-dimensional analyses the seabed must

be defined using a rigid surface, which must be flat and parallel to the global

X–Y plane.

This idealization of the drag chains is usually satisfactory for motions

several times larger than typical lengths associated with these chains

().

For small motions (of order )

the model is too idealized, and the chain must itself be modeled. Since the

majority of installation procedures involve considerable motion, the model is

usually adequate.

Problem description

The example used here to illustrate the process consists of a pipe of length

304.8 m (1000 ft), with an outer diameter of 228.6 mm (0.75 ft) and a wall

thickness of 7.62 mm (0.025 ft). This is a rather slender beam, and for this

reason hybrid beam element type B23H is chosen. (The “hybrid” beams are mixed formulation elements

designed for use with very slender or very stiff systems.) One end of the

pipeline is winched into an anchor point that is initially offset 121.92 m (400

ft) to one side of the pipeline and set back 91.44 m (300 ft) from the end of

the pipeline. The other end of the pipeline is assumed to be built in—that is,

already fully attached to some rigid fixture, as indicated in

Figure 3.

There are six equally spaced drag chains on the pipeline, and so for

convenience five elements are used to idealize the pipeline. Drag chains are

attached to the nodes. The chain at the end being winched has a mean length at

slip, ,

of 7.62 m (25 ft) and requires a force of 556 N (125 lb) to slip. The other

chains are all of equal size, with a mean length at slip of 1.524 m (5 ft) and

a slip force of 111 N (25 lb).

For comparison purposes the analysis is also performed using

three-dimensional drag chains. For this case hybrid beam element type B33H is used, and the z-displacements at all of

the beam nodes are restrained to reproduce the two-dimensional case. The

equivalent three-dimensional parameters are obtained based on the description

outlined in

Drag Chains.

The chain at the end of the pipe will have a total length

of 39.9 m (131 ft), a friction coefficient

of 0.3, and a weight per unit length of 58.2 N/m (4.0 lb/ft). The remaining

chains have a total length

of 7.98 m (26.2 ft), a friction coefficient

of 0.1, and a weight per unit length of 1455 N/m (100 lb/ft). The height of the

beam above the seabed, h, is 3.05 m (10 ft). A cylindrical

analytical surface with a fixed reference node is used to simulate the seabed.

The reference node is used as the second node of the DRAG3D element to associate the drag chains with the seabed.

The cable is modeled as a spherical gap element, which provides for an

inextensible cable supporting tension but no compression. The length of the

cable can be changed throughout a step by using a contact interference. This

feature is used here to reduce the length to zero over the step and, thus,

effect the pull-in.

Boundary conditions

For the pull-in analysis the left-hand end of the pipe is assumed to be held

rigidly, including full rotational restraint. For the three-dimensional

analysis the beam nodes are also restrained in the -direction

to simulate the two-dimensional case. The rigid surface reference node is fully

restrained in all six degrees of freedom. The anchor point node is restrained

in all directions in this case, since the pull-in is toward a fixed point.

For the near-bottom tow analysis the pipeline is unrestrained for the

analysis using DRAG2D elements; however, when DRAG3D elements are used, the pipeline is restrained in the

-direction

as described above. The tow is up the y-axis: the anchor

point is fixed in the x-direction, and a motion of 304.8 m

(1000 ft) is prescribed in the y-direction. This implies

that the pipeline has no restraint (and is, therefore, singular) until the drag

chain extends sufficiently to stabilize the pipeline. To overcome numerical

difficulties in the early stages of the analysis, soft springs are attached to

two pipeline nodes. When the system is no longer singular, the solution

proceeds smoothly, with the automatic time incrementation algorithm controlling

the increment size.