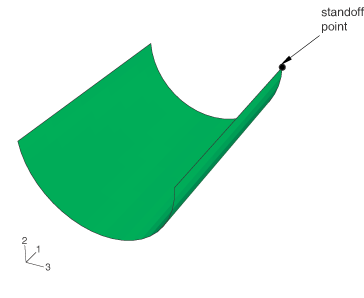

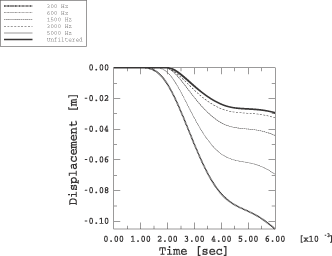

First, convergence of the structural response at the standoff point is

examined, applying the original KF loading

signal. Errors are reported in a -norm

over the entire 6 ms duration of the response. The converged solution is formed

by successively applying finer meshes until a desired relative accuracy is

obtained. From

Figure 2

and

Table 1

we conclude that a mesh with h=0.025 m is a reference

solution. The solution with h=0.05 m can also be

considered converged; therefore, it can become the reference solution for

subsequent studies (the acceleration response differs by only 1.1% with respect

to the solution with h=0.025 m).

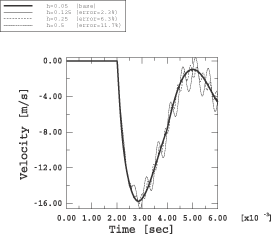

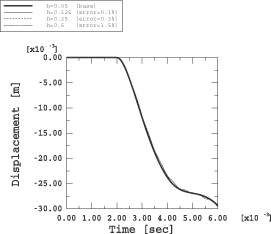

Figure 3

and

Figure 4

depict the relative accuracy of the displacement and velocity responses with

respect to the solution with h=0.05 m. For example,

Figure 3

shows that if an accurate velocity response is of interest, element size

restrictions can be relaxed to h=0.25 m (6.3% relative

error versus the reference configuration); if the displacement response is of

interest, the element size restrictions can be relaxed further to

m (Figure 4).

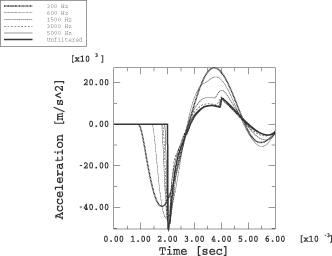

Figure 5

is constructed by defining a mesh characteristic frequency,

,

used as x-data for the error curve. For a given number of

elements, N, per excitation wavelength, the mesh

characteristic frequency is

where

is the characteristic wave speed (here the shell flexural wave speed) and

h is the element diameter. The structural wave speed is

dispersive; i.e., it varies with the excitation frequency. In

Figure 5,

however, a constant reference value of =1200

m/s is used. The previously defined mesh characteristic frequency also depends

on the user's choice of the number of elements per wavelength,

N. To preserve accuracy and to address the pollution

effect (Ihlenburg and Babuska, 1995), N should increase

with the excitation frequency. The choice of h,

N, and the wavespeed in the medium,

,

determines the value of the mesh characteristic frequency,

,

which can be interpreted as a cutoff frequency for designing the filtered

signal.

Figure 5

shows that by considering a mesh with h=0.05 m and

N=15, the mesh characteristic frequency becomes

=1600

Hz. If the number of elements per wavelength is relaxed to

N=5,

will increase to 4800 Hz. If the latter value is applied as the cutoff

frequency, the filtered signal will capture the true signal more accurately;

however, it is likely to produce more noise if the waves are not resolved

properly.

The study presented above may lead to meshes that are impractical for

realistic models, especially if the acceleration response is of primary

interest. For this model of 10 m length, an element of 0.05 m provides

sufficient accuracy at the standoff point. Since this may lead to prohibitive

computational costs for realistic models, the next studies address ways to

relax the element size restraints by modifying the shock signal applied to the

structure. These following studies examine the impact of filtering and modified

rise time upon the element size restrictions, in an attempt to minimize the

noise at coarse meshes.

Filtered signals are applied successively to the structure, in an attempt to

quantify the dependence of the optimal cutoff frequency on the element size.

The sine-Butterworth second-order filter is used. Although filter performance

is very important for optimal results, a comparison of various filtering

techniques is beyond the purpose of this study.

The filtered signals are postprocessed via linear scaling with the parameter

a such that the final and original signals are equivalent

in a n-norm:

The norm can be varied to design a final signal suitable for various

responses: since initially the KF is applied

as a load signal, the infinity norm is suitable for obtaining a more accurate

acceleration response, while the 1-norm (impulse conservation) is suitable for

obtaining a more accurate velocity response.

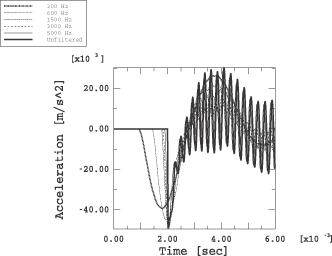

For this study filtered signals are designed with scaling parameters

suitable for acceleration response. Sample postprocessed filtered signals are

presented in

Figure 6.

By applying these as incident wave loads on the mesh with

h=0.05 m, the results shown in

Figure 7,

Figure 8,

and

Figure 9

are obtained for the acceleration, velocity, and displacement, respectively.

There is a clear distinction between

Figure 7—a

well-captured acceleration response—and

Figure 8

and

Figure 9—which

are poor estimates of the velocity and displacement responses—since the applied

filtered load has a significantly higher impulse than the unfiltered signal.

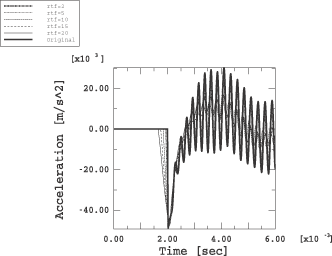

The results presented in

Figure 10

and

Figure 11

are obtained by applying the same load signals to coarser meshes. A summary is

presented in

Table 1

and

Figure 14.

The expected trend is visible: as the mesh coarsens, the acceleration response

when applying filtered signals is considerably less noisy than the response for

unfiltered signals. As the mesh is refined, the response converges to the

“wrong” solution given by the filter of choice. Thus, when computational

resources are scarce, there is an obvious benefit to applying prefiltered

signals, which attenuate the noise due to insufficient spatial discretization.

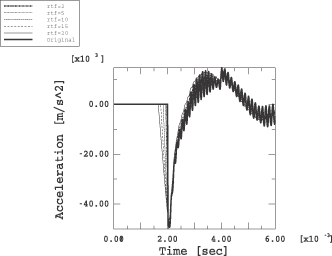

As an alternative to the sine-Butterworth filter, the signal can be

idealized in a heuristic manner by using a linear rise, followed by an

exponential decay. By keeping the decay constant, you can study the sensitivity

of the structural element size to the rise time of the shock signal.

The original rise time, ,

of the KF signal is multiplied by a rise time

factor (=

2, 5, 10, 15, 20) to obtain new signals, which are then applied to the

structure. To account for noise contributions only, the error of the

acceleration response is reported on the decay portion

[],

where

is the time stamp of the peak amplitude of the load signal.

The results using this technique are presented in

Figure 12

and

Figure 13

and summarized in

Table 2

and

Figure 15.

By comparison with

Figure 14,

the smoothing strategy appears considerably more effective for the acceleration

response than using a sine-Butterworth filter. For example, the case with

h=0.125 m and =20

(scaling the upper bound of the spectrum at ~2250 Hz) yields an error of 9%;

for the same element size with h=0.125 m, the

sine-Butterworth filter with a cutoff frequency of 3000 Hz yields a 32% error.