The bumper analysis is a two-step process. In the first step the

interference between the bumper's inner diameter and the mandrel is resolved.

In the

Abaqus/Standard

analysis the automatic “shrink” fit method (see

Common Difficulties Associated with Contact Modeling in Abaqus/Standard)

is used: the calculated initial penetration is allowed at the beginning of the

step and scaled linearly to zero at the end of the step. In the

Abaqus/Explicit

analysis the interference resolution step is performed in one of three ways. In

the first approach the initial penetration is solved using the "shrink” fit

method (the same as in the

Abaqus/Standard

analysis). In the second approach the mandrel is positioned so that no contact

or overclosure exists between the bumper and the mandrel at the outset of the

analysis. The rigid surface representing the mandrel is then moved in the

radial direction to simulate the compression of the bumper due to the

interference fit. In the third approach the shrink fit solution from

Abaqus/Standard

is imported into

Abaqus/Explicit.

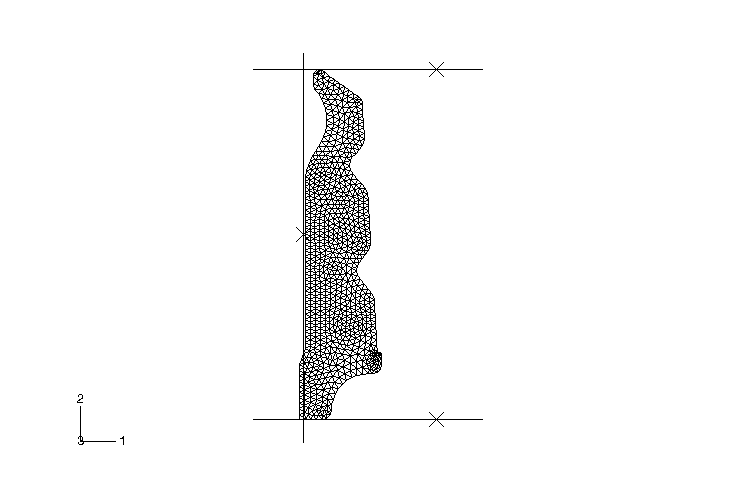

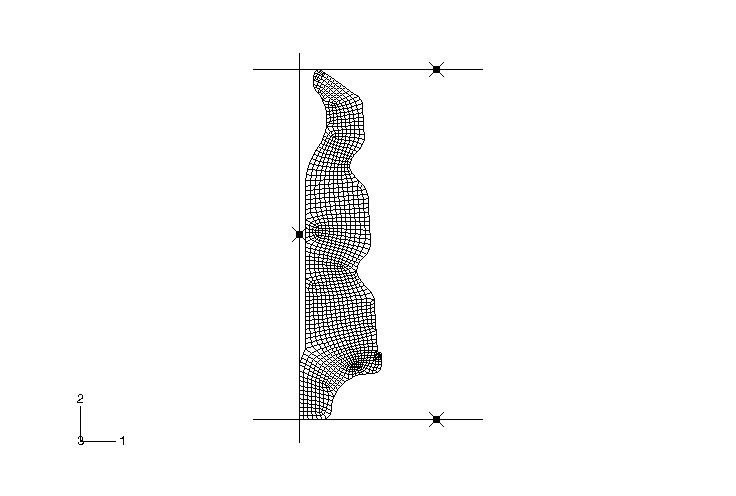

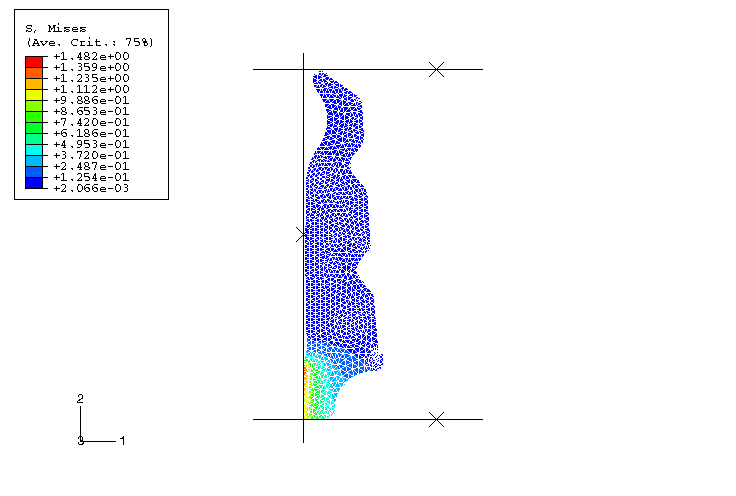

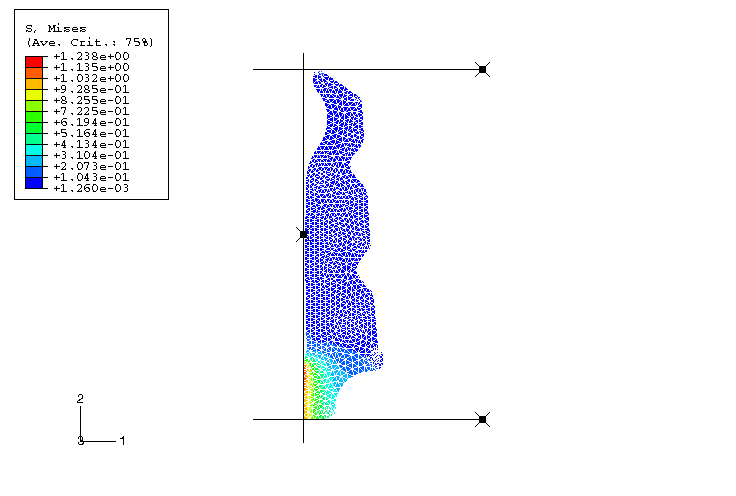

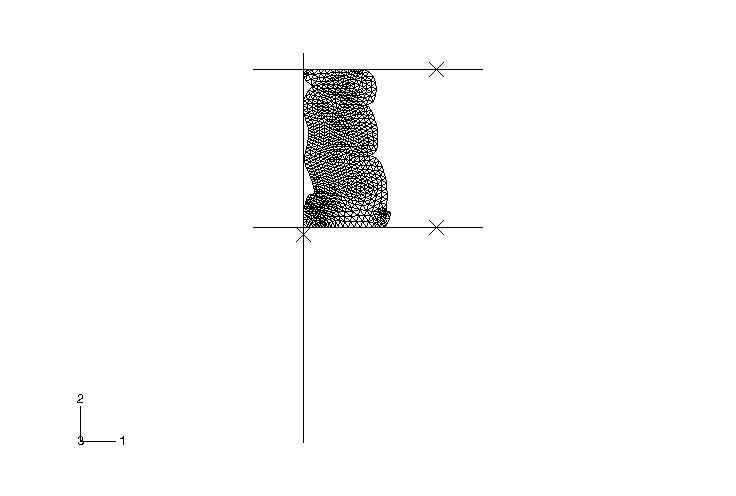

A comparison of the Mises stresses predicted by

Abaqus/Standard

and

Abaqus/Explicit

at the end of the interference step shows that the results are very similar

(see

Figure 3

and

Figure 4).

In the second step the bottom surface compresses the bumper 42.0 mm (1.7 in)

as a result of the application of displacement boundary conditions to the

reference node of the surface.

Figure 5,

Figure 6,

and

Figure 7

show the final deformed shape of the bumper; the high compressibility of the

material is apparent, as well as the folding of the surface onto itself.

Although a general knowledge of where the folding would occur was used in the

definition of the self-contacting surfaces, it is not necessary to know exactly

where the kinks in the surface will form.

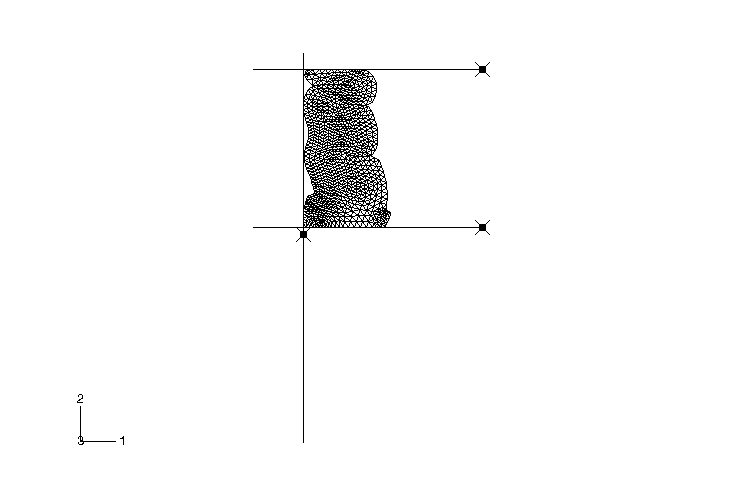

The final deformed shapes predicted by

Abaqus/Standard

and

Abaqus/Explicit

for the CAX3 element mesh are the same (see

Figure 5

and

Figure 6,

respectively). A similar shape is predicted by

Abaqus/Explicit

when CAX4R elements are used (see

Figure 7).

However, the solution obtained with CAX4R elements in

Abaqus/Explicit

reveals that local buckling occurs in the upper-left folding radius. This makes

a similar analysis using CAX4R elements in

Abaqus/Standard

very difficult. The local buckling is not captured in the CAX3 analysis due to the stiffer nature of these elements.

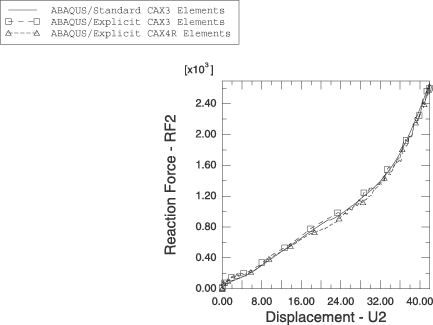

The load versus displacement curves of the bottom surface are shown in

Figure 8.

The results obtained with CAX3 elements in

Abaqus/Standard

and with CAX3 and CAX4R elements in

Abaqus/Explicit

are very similar. The energy absorption capacity of the bumper is seen through

these curves.