About Split by Volume Process | |||||

|

| ||||

Split by Volume

The split by volume process depends on the shipyard characteristics such as the crane size, the dry dock arrangement and the workforce. It is a necessary step towards process manufacturing and in parallel planning.

Before going for split by volume process, you should have:

- A set of structure systems containing the structural objects.

- Block plan that corresponds to the geometry of the volumes used to decompose the systems into the manufacturable assemblies.

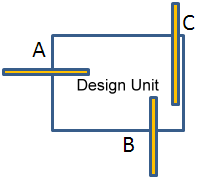

Design Unit

The split by volume process requires the creation of a design unit object. This object stores the volume information as well as the information about the planning break exceptions.

A design object must contain a volume to define the boundary. This volume can come from any skeleton model saved in the database, or can be created on the fly inside the design unit representation.

With a design unit, you can:

- Manage planning breaks exceptions.

- Calculate the weight and center of gravity per design unit.

Rules for Planning Break

The planning break rules correspond to the topological computation of the intersection between the design unit and the structure objects to determine the system status.

| When system status is... | An object is... |

|---|---|

| IN | Fully included in the design unit. |

| OUT | Fully excluded from the design unit. |

| ACROSS | In intersection with the design unit. |

| ON BOUNDARY | Lying on the boundary of the design unit. |

If a beam lies across the face of the design unit, the system status applies rule to distinguish between such cases. The rule uses the molded convention orientation.

| Structure Object | Rule | Illustration | Comment |

|---|---|---|---|

| Beam | ConfusionRuleBeam=MostofBeam (More than 50%) |  |

|

If a parametric panel lies across the boundary of the design unit, the system status is updated according to the location of the COG of the parametric panel. If the COG is inside the design unit, the system status is IN and the parametric panel is included.

Planning Break Exceptions

A change in the default topological status of a structure object is considered as an exception. The planning break exception is the operation of managing exceptions for planning breaks set for the functional elements contained in the structure systems. Once the planning breaks are created, you can edit offsets and replace some of the geometries by alternate geometries. If you do not manage exceptions, the split by volume process uses the default behavior.

- Panel

- A panel can be OUT, partly IN, fully IN, or ON BOUNDARY. You can decide to change and manage the exception. For example, the panel can be forced to be IN or forced to be OUT, or you can redefine the planning breaks using alternate geometry.

Important: - For the user-excluded panels, the system checks if they are synchronized to physical objects in other design unit. If there is an object limited to user-excluded panels, system supports re-routing of the limiting object to a physical object even though the limiting object is excluded by the user. This ensures that the physical objects have correct limiting objects and thickness compensation.

- When the limiting object is partially synchronized in the current design unit, re-routing of the limiting object to a physical object is performed only for synchronized objects in current design unit.

- Ensure that the synchronized user-excluded panels are loaded in the session to perform reroute.

- Profile: a Stiffener or a Beam

- The status is similar to the panel (OUT , partly IN, fully IN, or ON BOUNDARY) so the management of the exception is identical, IN or OUT. The planning breaks cannot be placed on beam. A beam can be only IN or OUT.