Creating a Worker Task | |||||

|

| ||||

-

In this scenario example, select an Operation (Tray positioning), and click

Add worker task

.

.

The Credit Dialog dialog appears.

Accept or Refuse. You can also select Do not show again.The Create worker task dialog box appears and a Worker Task.1 appears under 1 - Tray positioning.

- In the Create worker task, select Right, Get, and the AssemblyTray. Enter the Mass, 4kg.

-

Click Create.

A dialog box appears. Credit consumption - An evaluation will be consumed from your Evaluation package.

-

Click Yes.

Clicking Create in the Create Worker Task dialog box, is the only command that consumes one credit

10 to 9, from your Evaluation package.

The task automatically saves in the database. Using the Edit worker

task

10 to 9, from your Evaluation package.

The task automatically saves in the database. Using the Edit worker

task

dialog box, you can then modify your scenario. Clicking

Preview updates the manikins position in the modified

layout as many times as required, does not use any credits, and does not

automatically save. Once acceptable, click Update to save all

the new positions in the database and this also does not use any credits.

dialog box, you can then modify your scenario. Clicking

Preview updates the manikins position in the modified

layout as many times as required, does not use any credits, and does not

automatically save. Once acceptable, click Update to save all

the new positions in the database and this also does not use any credits.Your Evaluation Package credits decrease.

The Smart Posturing Engine computes the 4 manikins.

This shows a posture of the male manikin realizing the defined task. The anthropometry toolbar appears to show the status for each manikin. If there is a risk, then that manikin displays the risk.

Some of these SPE computations include:

- Position: The manikin position refers to the final position of the whole manikin in the environment after a posture is generated. The whole manikin position follows the root segment (attached to one of the feet), and is square to the workstation.

- Preposition: Refers to the initial position of the manikin before the SPE technology generates the whole body posture. This position is found automatically by analyzing the space around the target and the accessibility of the target object. The preposition can change within a predefined limit during the posture generation to accommodate the space required by the SPE to move the manikin while avoiding collision.

- Square: The manikin hips ought to be on the tangent of the smallest ray resulting from the sweeping around the Assembly, but allow a hip opening toward the object to grasp or toward the next task object to grasp.

- In Front: Manikin ought to be positioned so the Object is located in the front of the manikin with the hand located in the corresponding half body side, within the advised area.

Note: The manikin might end up at the wrong side of the workstation if the BuildUp position if the following do not provide adequate clues to decide the side of the workstation:

Note: The manikin might end up at the wrong side of the workstation if the BuildUp position if the following do not provide adequate clues to decide the side of the workstation:- BuildUp proximity to one side of the table.

- Work content such as tool orientation or previous tasks.

- Free space around the workstation.

-

Click Show the risk details

in the 3D Geometry

window.

in the 3D Geometry

window.

Shows suggestions and where the risk originates. -

Click First-Person Viewer

.

See Vision Window.

.

See Vision Window. -

Clicking View Task Specifications

shows

the requirements for that task.

shows

the requirements for that task.

-

Click each Manikin icon to change the manikin in the scenario.

See Each Manikin Risk.

-

Click Close.

This creates the Worker Task.1 under the Operation (Station).

If required in the Worker Task dialog, select,

Edit the worker Task - edits the worker task.

Edit the worker Task - edits the worker task. Delete the worker task - deletes.

Delete the worker task - deletes.-

Add

worker task before selection - to create a new task before the selected

task.

Add

worker task before selection - to create a new task before the selected

task.  Add

worker task after selection - to create a new task before the selected

task.

Add

worker task after selection - to create a new task before the selected

task.-

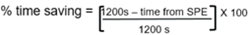

Improvement in percentile - indicates the time improvement

in a percentage to reach the resulting posture for the Worker Operation Detail. This

is based on an average time estimated at 1200 seconds from the testing group to the

position from the posture manikins.

Improvement in percentile - indicates the time improvement

in a percentage to reach the resulting posture for the Worker Operation Detail. This

is based on an average time estimated at 1200 seconds from the testing group to the

position from the posture manikins.

The long tooltip shows the comparison between the real time from the SPE and the average time required for a manual posture setting created by you.

Risk Improvement Badge - indicates if the Risk level optimized.

This shows a comparison between the current risk level and the previous risk level.

When the Risk Level worsens, the Risk Improvement badge displays as pale gray

star.

Risk Improvement Badge - indicates if the Risk level optimized.

This shows a comparison between the current risk level and the previous risk level.

When the Risk Level worsens, the Risk Improvement badge displays as pale gray

star.When the global Risk Level for a Worker Operation Detail remains unchanged after a new evaluation from the SPE, the Risk Improvement badge still displays the latest improved to level.

Risk Improvement Badge Meaning

The overall Risk Level has worsened compared to the previous result.

The overall Risk Level is not optimized and needs improvement

The overall Risk Level is better but can still be optimized.

The overall Risk Level is optimized. Because it is a comparison tool, no Risk Improvement badge displays at the creation of a Worker Operation Detail. The Long tooltip shows the potential cost for the given Worker Operation Detail in term of musculoskeletal disorders.

The Product Build Up also updates.

- Clicking the Station also gives a Overview toolbar summary of the risks.

-

Click on any risk level icon.

The Worker Tasks Summary appears.

.

Or the icon between the four selections is not acceptable.

.

Or the icon between the four selections is not acceptable.