Defining Macros on Turning Operations | |||

| |||

- Double-click Longitudinal Rough Turning operation in the Manufacturing Program.

-

Select the Macro Parameters tab

.

.

See Macros

The initial status of all the Macros in the Macro Management list is Inactive. - Right-click the Approach Macros line and click Activate in the context menu to activate

the Macros.

Note: You can also activate or deactivate macros by double-clicking an item in the list.

- Select the

Axial radial mode

in the Current Macro Toolbox.

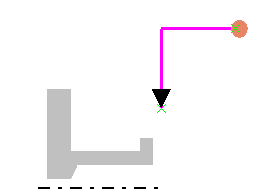

A sensitive icon representing the paths of the approach Macros appears.

- Select the point symbol in the sensitive icon then select

a point in the work area. The radial and axial paths of the Macros are calculated from the selected point to the start point of the operation.

- Select the

Axial radial mode

in the Current Macro Toolbox.

-

Click Simulate or Display to check the axial approach.

The status of the Macros becomes Up to date.

- Right-click the Retract Macros line and click Activate in the context menu to activate

the Macros.

Note: You can also activate or deactivate macros by double-clicking an item in the list.

- Select the

Radial axial mode

in the Current Macro Toolbox.

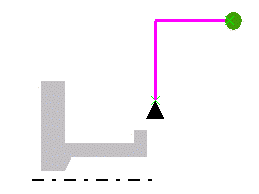

A sensitive icon representing the paths of the approach Macros appears.

- Select the point symbol in the sensitive icon then select

a point in the 3DEXPERIENCE platform. The axial and radial paths of the macro are calculated from the end point of the Machining Operation to the selected point.

-

Click Simulate or Display to check the axial retract.

The status of the macro becomes Up to date.

- Select the

Radial axial mode

in the Current Macro Toolbox.

-

Select the Different colors mode

in the

dialog box, to visualize feedrate changes.

The tool path is displayed with the following default colors:

in the

dialog box, to visualize feedrate changes.

The tool path is displayed with the following default colors:- Yellow: Approach or lead-in feedrate

- Green: Machining feedrate

- Blue: Retract feedrate

- Red: Rapid or lift-off feedrate

- White: User-defined feedrate

Note: Transition paths are represented by dashed white lines. - Define the Linking Approach and Linking Retract macros in the same way as discussed above.

- Define

interrupt conditions for the Linking Macros in the Options

tab of the Current Macro Toolbox, if required.See Macro Parameters

- Click OK to accept the modifications made

to the Machining Operation.The Machining Operation is updated with the specified macros.

If a collision is detected on an NC Macro, its parameters are locally modified to avoid collision with the part. If an NC Macro is modified, a message appears in the Messages Reporting dialog box. Collisions are detected by checking the interference between the tool insert section and the part profile in the turning view.