Load PPR Objects from Manufacturing Finder Without Any Resulting Products

You can load PPR objects from the Manufacturing Finder without

any resulting products.

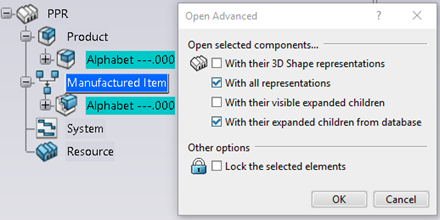

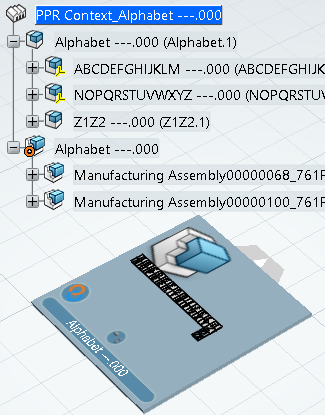

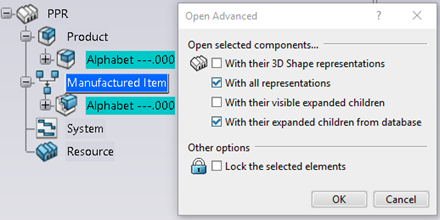

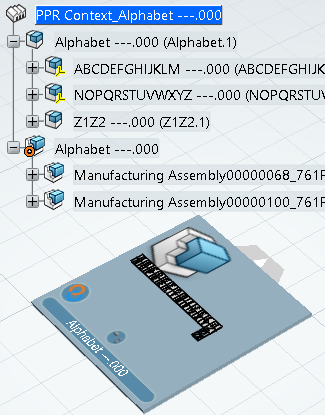

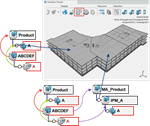

Open Full PPR Objects

- From navigation, open all objects with the following options.

- All objects (Product + Manufactured

Item) load without any resulting product. The following icon stands for

unloaded resulting product and appears on the tile.

- To load the resulting products on demand, RMB on a tile of the manufactured item and

click Resulting Product, Load Resulting

Product context menu. Or click Load Resulting

Product in Authoring

action bar after selecting a manufactured item.

- The Information dialog appears with the message,

Loading Resulting Products and all commands are unavailable

until the operation is completed but the interaction with the viewer is still possible.

The Stop allows you to interrupt the current operation (load of

resulting products). It takes time depending on the server status and the size of the

resulting products in the database (DB).

- After loading, the message, Successfully resulting products

appears on the right corner of the application and then the tiles refresh.

- Open a resulting product of the root Manufacturing Assembly in

the new tab, the resulting products open in the session.

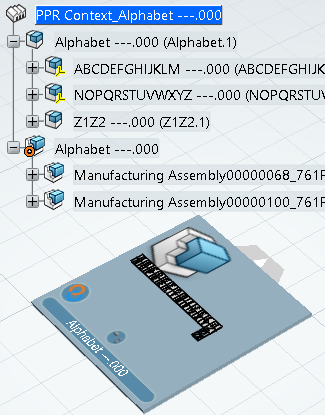

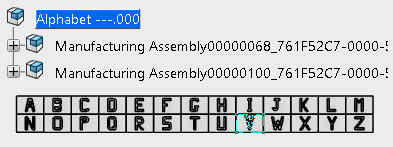

Open Partial MBOM

- From the navigation, open visible objects with the following options.

- Visible objects (Product + Manufactured

Item) load without any resulting product.

- To load the resulting products on demand, RMB on a tile of the manufactured item and

click Resulting Product, Load Resulting

Product context menu. Or click Load Resulting

Product in Authoring

action bar after selecting a manufactured item.

- The Information dialog appears with the message,

Loading Resulting Products and all commands are unavailable

until the operation is completed but the interaction with the viewer is still possible.

The Stop allows you to interrupt the current operation (load of

resulting products). It takes time depending on the server status and the size of the

resulting products in the database (DB).

- After loading, the message, Successfully resulting products

appears on the right corner of the application and then tiles refresh.

- Open a resulting product of the root Manufacturing Assembly in

the new tab, the resulting products partially open in the session.

Load Resulting Product Command

This loads either;

- Resulting products for all manufactured items in the session when no selection

- Resulting products for selected manufactured items in the session

When a manufactured part aggregates, two transforms it selects and the command starts,

the resulting products of the manufactured part and the children transforms the load in

the session.

Selecting a child manufacturing assembly and launching the command, the resulting

products for children of selected manufacturing assembly and their parents load in the

session. Not loading are other manufacturing assemblies that are in the same hierarchy.

Representations like drawing and 3DShape aggregated under the resulting products load as

well.

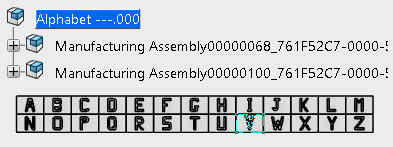

Generate Manufactured Items Without Any Resulting Product

Manufactured items generate for input products with no resulting product by default

through Generate MBOM, Synchronization Manager and

Drag and Drop functionalities. Fewer objects

generate in the session. Therefore, it reduces the elapse time of MBOM generation and

saving.

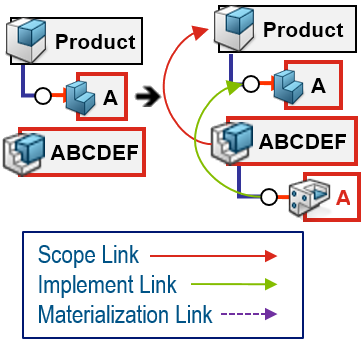

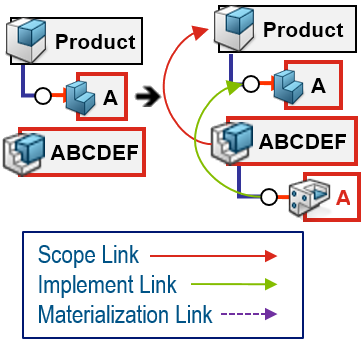

Update Resulting Product Structure for Manufactured Items

You can update the resulting product structure and accessible by context menu of the

selected manufactured item and the Authoring section in the action bar.

In the previous step, manufactured items generate with no resulting product. Thus, the

resulting products create and have the hierarchy (MA structure) because of this.

- Selecting nothing, all manufactured items in the session are candidates to have the

resulting product structure.

- Selecting some manufactured items, then selected items and their direct/indirect

children are candidates.

- When manufactured items do not have any resulting product, the resulting products

generate for these items.

- When manufactured items have resulting products but not loaded yet in the session,

they load in the session first and then the update performs.

- When the resulting products, which, had materialization links with deleted

manufactured items are to delete from the MA structure. When manufactured items do not

load in the session by filtering in the Manufacturing Finder,

they cannot consider as deleted when performing an update.

- When the resulting products of manufactured items generate but do not aggregate under

the parent resulting product, they take into account by the command.

Visualization of Auxiliary Viewer

When the Auxiliary Viewer initializes, Show Assigned

Parts as Transparent and Unassigned Parts is specify by default. In the case of

assigned parts, products, which implement by manufactured items visualize instead of resulting

products because they do not load yet in the session. However, once the resulting products

load in the session, they visualize in the Auxiliary Viewer instead of

the products. In the case of unassigned parts, products, which do not implement by any

manufactured item visualize as usual.

Part List in Auxiliary Viewer

Earlier in the Product tab of Part List,

parts in Mfg Item State were input product aggregated under the

resulting product. Since no resulting product loads in the session, the input product views as

a Mfg Item State if assign to the manufactured item. Context menus for

this kind of parts are working as it is.

Fasten items are displayed in the Item tab of the Part

List.

Common Message Box

The common message box appears when following commands, which are requiring a

resulting product start. Capable Resource List, Extract Production Drawing, Open Workshop

Document and Plug In Design Features.

The message box asks you to load the resulting products on demand to use the commands. This

appears only when the resulting product of some manufactured item does not load yet in the

session.

Interaction of the message box:

- The dialog is modal.

- Enter key equals to clicking Yes.

- Esc key equals to clicking No.

- Detail message is seen/hidden when clicking Expand/Collapse.

- Check box allows you to save the preference.

- After selecting the box and clicking Yes or

No, the dialog box disappears. The resulting products load or

not from the next time according to the option.

- This is cleared by default.

- Remove

DELShipMfgLoadResultingProductPreference.CATPreferences file

to restore the option.

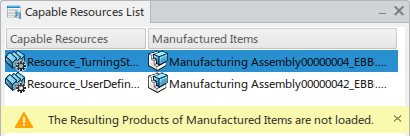

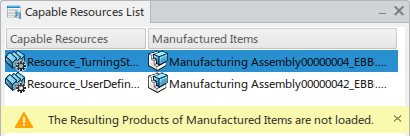

Capable Resource in Auxiliary Viewer

Selecting Show Capable Resource, the panel appears with the list

of capable resources in the session.

After selecting a row in the list and the resulting product of manufacturing assembly does

not load in the session, the common message box appears. Clicking

Yes, the resource and resulting product appear in the

Auxiliary Viewer.

Otherwise, only the resource is visualized in the Auxiliary Viewer

and a warning message is seen in Capable Resource List panel at the

bottom.

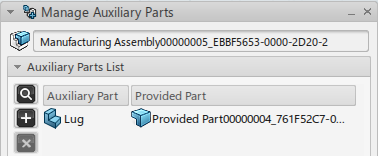

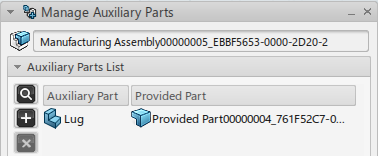

Manage Auxiliary Parts Command

This does not load or open any resulting product.

Launching and trying to have new auxiliary parts, then new provided parts create and the

resulting products create as well.

If the parent manufacturing assembly has a resulting product and it is in the session, the

resulting products of the new auxiliary parts are aggregated under the MA.

Deleting auxiliary parts does not take into account the updating of the resulting product,

clicking Update Resulting Product Structure afterward if required.

Plug in Design Features

You can start this and select a manufacturing assembly that no resulting product

loads yet.

Selecting Plug In-Design Features, and selecting the assembly, the

Unloaded Resulting Product dialog box appears. Selecting

Yes, the resulting product of selected manufacturing assembly loads

in the session and adds a row for the input.

Select No. The resulting product does not load in the session and it

does not consider it as input for this command. A warning message appears, The

Resulting Products of Manufactured Items are not loaded.

Extract Production Drawing

After launching the Extract Production Drawing and selecting a

manufacturing assembly and its resulting product does not load in the session, the

Unloaded Resulting Product appears.

Selecting Yes, the resulting product of selected manufacturing

assembly loads in the session and adds a row for the input.

Selecting No, the resulting product does not load in the session. It

is not considered as input for this command with a following warning message, The

Resulting Products of Manufactured Items are not loaded.

Open Workshop Documents

After launching the Open Workshop Documents and selecting a

manufacturing assembly, which has a drawing and an unloaded state, its resulting product does

not load in the session. The Unloaded Resulting Product

appears.

Selecting Yes, the resulting product of selected manufacturing

assembly loads in the session and the documents are retrieved and displayed in the

panel.

Otherwise, the warning message appears at the bottom of the panel. The BOM

XML can retrieve although no resulting product loads.

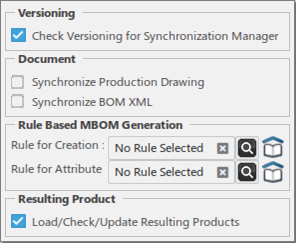

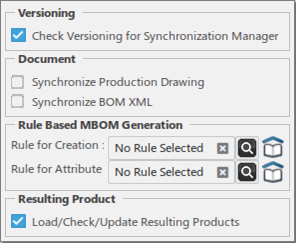

Synchronization Manager

After launching the Extract Production Drawing and selecting a

manufacturing assembly and its resulting product does not load in the session, the

Unloaded Resulting Product appears.

See About Synchronization Manager and Revising a Fasten Item with Synchronization Managerfor more information on Resulting

Product.

When the option for the resulting product is OFF, then the option

for revision is disabled. Revised status is considered as deleted status when the option is

OFF.

Computing with the option ON, the resulting products of manufactured

items load. Here is available status and actions after computation.

- Option ON

- New – Create/None:

- No manufactured item for product found. Sync performs manufactured item and

resulting product creation.

- New – Update/None:

- No resulting product for manufactured item found. Sync performs a resulting

product creation.

- Resulting product exists but isolates somewhere. Sync performs correct

aggregation.

- Modified – Acknowledge/None:

- Manufactured item has resulting product and changes of input product detected.

Sync performs update of time stamp on manufactured item.

- Deleted – Delete/None:

- Manufactured items with no implement link. Sync performs manufactured item and

resulting product deletion.

- Revised – Reroute/None:

- Finding a broken implement link, revisions of input product and product

aggregated under the resulting product are equal. Sync performs rerouting the

implement link.

- Revised – Revise/None:

- Finding a broken implement link, revisions of input product and product

aggregated under the resulting product are not equal. Sync performs new revision

creation and replacement of it.

- Revised – Review/None:

- Finding a broken implement link, but revision computation is impossible because

the resulting product is out of existence. Sync performs nothing for this action,

Set Revision step is mandatory for further process.

Details are:

- Up-To-Date – None:

- Manufactured item and resulting product are existing.

- Option OFF

- New – Create/None:

- No manufactured item for product found. Sync performs manufactured item

creation.

- Modified – Acknowledge/None:

- Manufactured item has resulting product and changes of input product detected.

Sync performs loading of the resulting product and update of a time stamp on the

manufactured item.

- Deleted – Delete/None:

- Manufactured items with no implement link. Sync performs manufactured item

deletion. Resulting product structure updates manually by the command.

- Up-To-Date – None:

- Manufactured item is existing for product.

When the option is ON and a product is yet assigned to any

manufactured item and click Compute, the result.

| EBOM |

MBOM |

Status |

Action |

Parent |

Product1.A Product1.A |

None |

New |

Create |

--- |

Clicking Synchronize, the result is as following. A new manufactured

item creates for the product and its resulting product also creates for the manufactured

item.

| EBOM |

MBOM |

Status |

Action |

Parent |

Product1.A Product1.A |

MfgPart1.A MfgPart1.A |

Up-To-Date |

None |

--- |

When the option is OFF and a product is not yet assigned to any

manufactured item and click Compute, the result.

| EBOM |

MBOM |

Status |

Action |

Parent |

Product2.A Product2.A |

None |

New |

Create |

--- |

Click Synchronize, the result. As the option is

OFF, only a manufactured item generates for the given product.

Other manufactured items, which have no resulting product are

Up-To-Date in this case.

| EBOM |

MBOM |

Status |

Action |

Parent |

Product2.A Product2.A |

MfgPart2.A MfgPart2.A |

Up-To-Date |

None |

--- |

When the option is ON, click Compute again,

the result. After synchronization, the Status is

Up-To-Date.

| EBOM |

MBOM |

Status |

Action |

Parent |

Product1.A Product1.A |

MfgPart2.A MfgPart2.A |

New |

Update |

--- |

For Modified Status, the matrix change does not detect it by the

Compute operation when loading a resulting product of the

manufactured item in the session. However, other changes like attribute value modification

or geometry change are detected as normal by Compute operation.

| Modified Status by |

Detectable when output is unloaded |

| Matrix Change |

No |

| Attribute value modification |

Yes |

| Geometry Change |

Yes |

Set Parent context menu is disabled when a selected row is

New/Update.

Specify Revision

This menu mainly focuses on Revised status and

Review action in Synchronization Manager.

However, it is available for all actions of Revised status.

RMB on a row for revised status. In this scenario, select six rows for revision and then

click the context menu. The new dialog appears for selected rows.

There are 3 columns:

- Manufactured Item: Current manufactured item.

- Candidate: List of revisions for the current manufactured item,

the value can modify by the field selection. By default, the best candidate appears for

the given manufactured item.

- Action: the action updates according to the current manufactured

item and the candidate manufactured item. Available actions are;

- Reconnect

- Replace by New Revision

- Replace by Existing Revision

Clicking OK, Review action updates to

Revise action and Synchronize takes into

account the actions. Otherwise, Review action stays as it is.

|

Product1.A

Product1.A MfgPart1.A

MfgPart1.A