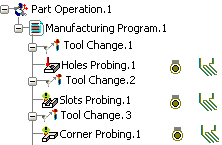

Creating Probing Corners | |||||

|

| ||||

-

Activate the Manufacturing Program and select Corner Probing

in the Prismatic Machining action bar.

A Corner Probing entity is added to the Manufacturing Program. The Corner Probing dialog box opens directly at the Geometry tab page

in the Prismatic Machining action bar.

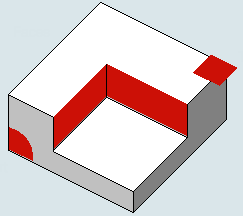

A Corner Probing entity is added to the Manufacturing Program. The Corner Probing dialog box opens directly at the Geometry tab page . This tab includes a sensitive icon to

help you specify the

geometry.

Areas of the icon are colored red indicating that this

geometry is required. The Probing side selections Inside or Outside.

. This tab includes a sensitive icon to

help you specify the

geometry.

Areas of the icon are colored red indicating that this

geometry is required. The Probing side selections Inside or Outside.

-

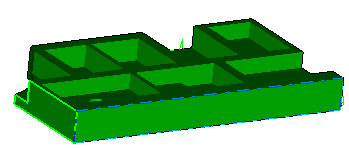

Still in the Geometry tab:

- Select the red area in the sensitive icon and select the part in the 3DEXPERIENCE platform.

- Double-click anywhere in the 3DEXPERIENCE platform to confirm your selection and redisplay the dialog box.

- Similarly, Select Face in the sensitive icon and select the faces that limit the corner in the 3DEXPERIENCE platform.

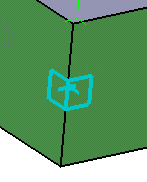

A corner symbol appears to visualize how the corner is processed. If this information is not correct.

Select the wings of the corner until they show the correct way.

- Select Top and select the top plane.

- Select the Strategy tab

and specify the strategy and user parameters:

and specify the strategy and user parameters: - Go to the Tool tab

to select a tool.

to select a tool. - Select the Feeds and Speeds

tab

to specify the feedrates

and spindle speeds for the operation.

to specify the feedrates

and spindle speeds for the operation. - Select the Macro tab

to specify the desired transition paths.

to specify the desired transition paths.

-

Select Display or

Simulate to check the validity of the operation.

- The probing tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100% completion.

-

Select OK in the Display or

Simulate dialog box, and again in the main dialog box.

The probing tool path is created: