Create a Point to Point Operation

You can create an operation using Point to Point

command.

-

Activate the

Manufacturing Program and click Point

to Point

from the Prismatic Machining section of the action bar.

from the Prismatic Machining section of the action bar.

The Point to Point workflow appears in the work area.

The Motions tab allows you to define a list of

elementary motions Goto Point,

Goto Point,  Goto Position and

Goto Position and  Go Delta motions to make up the machining operation.

Go Delta motions to make up the machining operation.

-

Follow the workflow instructions to create a point to point

operation.

A Point to Point entity is added to the

Manufacturing Program.

The Point to Point dialog box appears directly in

the Tool tab  . .

-

Click

in the title bar of the dialog box to edit the name of the manufacturing

pattern, such as PointToPoint.x.

in the title bar of the dialog box to edit the name of the manufacturing

pattern, such as PointToPoint.x.

-

Select a tool.

See Assigning a Tool Element to a Machining Operation

-

Select the Strategy tab

, select

a feature and do one of the following: , select

a feature and do one of the following:

-

Click

Goto Point, then select a corner point on the

underside of the part. Double-click to end point selection.

Goto Point, then select a corner point on the

underside of the part. Double-click to end point selection.

The first tool motion is defined and appears in the list in the

dialog box.

-

Click Goto Position

. .

A Sequential Motion dialog box

appears to help you specify the part, drive, and check elements as well as

positioning conditions ( To /

On / Past).

-

Click OK.

The second tool motion is defined and appears in the list in

the Point to Point dialog box.

-

Add other Goto Point, Goto

Position, and Go Delta

motions as required.

-

Click

PP words and specify the desired syntax to

add PP words to the list .

PP words and specify the desired syntax to

add PP words to the list .

-

Move motions up or down the list using the arrows.

-

Click

Delete to remove motions.

Delete to remove motions.

-

Right-click any tool motion to access the context menu.

-

Specify the Machining tolerance.

-

Select the Macros tab

to specify

the desired transition paths. to specify

the desired transition paths.

See Defining Macros on Milling Operations

-

Click Compute to compute the tool path with the

specified parameters.

-

Click OK to validate and exit the dialog box.

-

Click Cancel to exit the dialog box without

saving.

The point to point operation is created as

PointToPoint.x. It is visible in the Activities Process Tree.

Create a Point to Point Operation with the Legacy Interface

You can create an operation using Point to Point

command.

-

Activate the

Manufacturing Program and click Point

to Point

from the Prismatic Machining section of the action bar.

from the Prismatic Machining section of the action bar.

A Point to Point entity is added to the

Manufacturing Program.

The Point to Point dialog box appears directly at

the Tools tab  . .

The Motions tab allows you to define a list of

elementary  Goto Point,

Goto Point,  Goto Position and

Goto Position and  Go Delta motions to make up the machining operation.

Go Delta motions to make up the machining operation.

-

Select the Strategy tab

, which

comprises tabs Motions (to define the elementary

motions making up the machining operation), Strategy,

and User Parameters. , which

comprises tabs Motions (to define the elementary

motions making up the machining operation), Strategy,

and User Parameters.

-

Go to the Motions tab.

-

Click

Goto Point, then select a corner point on the

underside of the part. Double-click to end point selection.

Goto Point, then select a corner point on the

underside of the part. Double-click to end point selection.

The first tool motion is defined and appears in the list in the

dialog box.

-

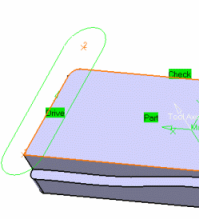

Click Goto Position

. .

A Sequential Motion dialog box

appears to help you specify the part, drive, and check elements as well as

positioning conditions ( To /

On / Past).

-

Click OK when you have specified the desired

elements and conditions.

The second tool motion is defined and appears in the list in

the Point to Point dialog box.

-

Add other Goto Point, Goto

Position, and Go Delta

motions as shown in the figure below.

| Motions |

| Rank |

Name |

Type |

Position on

Drive |

Position on Check

|

|

1

2

3

4

5

6

7

|

Positionmotion.1

Positionmotion.2

Positionmotion.3

Positionmotion.4

Positionmotion.5

Positionmotion.6

Deltamotion.1

|

Point

Position

Position

Position

Position

Point

Delta

|

-

On

To

On

Past

-

-

|

-

Past

On

Past

On

-

-

|

-

Click

PP words and specify the desired syntax to

add PP words to the list .

PP words and specify the desired syntax to

add PP words to the list .

-

Move motions up or down the list using the arrows.

-

Click

Delete to remove motions. Delete to remove motions.

-

Click

Properties to edit the properties of a

motion.

Properties to edit the properties of a

motion.

-

Go to the Strategy tab to specify machining

parameters.

-

Right-click any tool motion to access the context menu.

-

Click the plane symbol in the sensitive icon to specify an

indication plane and select a plane or planar face or enter X, Y, Z

coordinates in the Indication Plane dialog

box that appears, if required.

-

Double-click the text in the sensitive icon to specify an offset along the tool axis.

-

Select the axis representation in the sensitive icon to define the

tool axis direction in the Tool Axis dialog

box that appears.

Note:

This is the global axis, which is the default axis that is

applicable to all points of the operation. However, you can

specify different local axes for different points in the

operation.

-

Go to the User Parameters tab to specify user

parameters.

See Adding a User Parameter

-

Go to the Tool tab

to select a tool, in the

Pocketing dialog box. to select a tool, in the

Pocketing dialog box.

See Assigning a Tool Element to a Machining Operation

-

Select the Feeds and Speeds tab

to specify

the feedrates and spindle speeds for the operation. to specify

the feedrates and spindle speeds for the operation.

-

Select the Macros tab

to specify

the desired transition paths. to specify

the desired transition paths.

See Defining Macros on Milling Operations

-

Click Display or

Simulate to check the validity of the operation.

See Simulating the Tool Path.

- The tool path

is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100%

completion.

-

Click OK to create the operation.

Notes:

- You can right-click the motions displayed in the 3DEXPERIENCE platform to access context menu to insert or remove point positions and to assign local

feedrates.

- If you select a circle, its center is taken as the point to

machine.

- Points of an associated sketch can also be selected.

- Points is defined by clicking on a user-defined indication

plane.

- Points is defined by entering X, Y, Z coordinates in the motion

editor. Point coordinates are defined in the machining axis system.

Define the Local Tool Axis

The tool axis is defined while selecting the point itself. The tool axis

orientation depends on the orientation of the selected element (line, edge). The same

procedure applies to Go Delta motions.

-

In the Strategy tab, click the tool axis in the

sensitive icon and define it in the dialog box that appears.

See Defining the Tool Axis

This tool axis is the global axis that is applied by default to all

the points of the operation, unless you define a local axis for a

point.

-

Go to the Motion tab, click Goto

Point

and select a point. and select a point.

The local tool axis is displayed on the point you have

selected.  -

Either:

-

Select further points without editing their local axis.

The global axis is applied to all the points you have

selected.

-

Right-click this tool axis and select Edit local

axis in the context menu to define it.

This local axis is used on that point. Note:

Once you have

defined a local axis, this local axis (not the global axis) is

applied to the next points you select, unless you define another

local axis for that given point.

-

To edit any local tool axis, if required.

- Right-click and select from its context menu in the 3DEXPERIENCE platform,

- Right-click and select from its context menu in the dialog box,

- Clicking

and modifying the tool axis in the dialog

box. and modifying the tool axis in the dialog

box.

|

from the Prismatic Machining section of the action bar.

from the Prismatic Machining section of the action bar.

Goto Point,

Goto Point,  Goto Position and

Goto Position and  Go Delta motions to make up the machining operation.

Go Delta motions to make up the machining operation. .

. in the title bar of the dialog box to edit the name of the manufacturing

pattern, such as PointToPoint.x.

in the title bar of the dialog box to edit the name of the manufacturing

pattern, such as PointToPoint.x.

, select

a feature and do one of the following:

, select

a feature and do one of the following:

Goto Point, then select a corner point on the

underside of the part. Double-click to end point selection.

Goto Point, then select a corner point on the

underside of the part. Double-click to end point selection.

.

A Sequential Motion dialog box appears to help you specify the part, drive, and check elements as well as positioning conditions (To / On / Past).

.

A Sequential Motion dialog box appears to help you specify the part, drive, and check elements as well as positioning conditions (To / On / Past).

PP words and specify the desired syntax to

add PP words to the list .

PP words and specify the desired syntax to

add PP words to the list .

Delete to remove motions.

Delete to remove motions.

to specify

the desired transition paths.

to specify

the desired transition paths.