Creating a Sequential Axial Operation with the Legacy Interface | ||||

|

| |||

-

From the

Axial Machining section, select Sequential

Axial

then

a position in the Manufacturing Program.

then

a position in the Manufacturing Program.

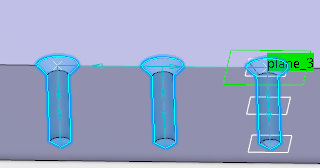

A typical part to machine with Sequential Axial looks like this:

- A Sequential Axial entity is added to the Manufacturing Program.

- The Sequential Axial dialog box opens directly at

the Geometry tab

. This

tab includes a sensitive icon to help you specify the geometry.

. This

tab includes a sensitive icon to help you specify the geometry. - Areas colored red, or texts such as No point and No geometrical feature has been selected, indicated that geometry is required.

-

Still in the Geometry tab, which comprises a

Global and a Local tab:

-

In the Global tab, select the red hole depth

representation then select the three holes.

See Selecting Geometry for more information.

The sensitive icon is updated with information such as:

- The number of machining points.

- The depth and diameter of the first selected hole.

- The counterbore depth.

- The angle.

-

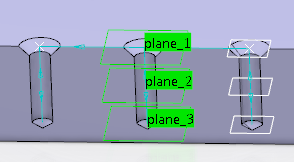

In the Local tab, select the plane representations

in the sensitive icon, and the required planes in the part.

- Optional: Select the axis representation in the sensitive icon to invert the tool axis direction.

- Optional: Select the check boxes below the sensitive icon to modify the corresponding data.

-

In the Global tab, select the red hole depth

representation then select the three holes.

-

Select the Strategy tab

to specify the

following parameters.

to specify the

following parameters.

- Power

- Approach clearance (A)

- Compensation parameters, such as First Compensation and Compensation Application Mode. These depend on those available on the tool.

- Automatic ROTABL

- Output CYCLE syntax

-

Select the Motions tab in the

Strategy tab

and define the

required motions.

and define the

required motions.

- Click the icon corresponding to the required motion.

- From the lists, select or enter the values.

- Click OK to add the motion.

For example:

Motion Icon Syntax Parameter 1st Spindle Speed

SPINDL/ 60,000,RPM,CLLW Spindle Mode = Local Spindle (60tr/mn)

Way of Rotation=CCLW

2nd Go to Plane

- Plane number=1

Feedrate Mode = Local Feedrate (50mm_mn)

3rd PP Word

COOLNT/CENTER,70 4th Delay

DELAY/ 3.000000 Spindle Dwell Time=By Time

Spindle Dwell Time (3s)

5th Go to Plane

- Plane number=3

Feedrate Mode = Machining

6th Go to Clearance

- Feedrate Mode = Local Feedrate (50 mm_mn

The motions are added and listed in the dialog box. -

Select the Tool tab

and choose a tool.

Note: The following mill tools available:

and choose a tool.

Note: The following mill tools available:- Drill

- Multidiameter drill

- Spot drill

- Center drill

- Countersink

- Two sides chamfering

- Boring and chamfering

- Boring bar

- Reamer

- T-slotter

- end mill

- Face mill

- Thread mill

- Conical mill

- Counterbore

-

Select the Feeds and Speeds tab

to specify the

feedrates and spindle speeds for the operation.

to specify the

feedrates and spindle speeds for the operation.

-

Select the Macros tab

to specify the

required transition paths.

to specify the

required transition paths.

-

Click Display or

Simulate to verify the validity of the operation.

- The progress indicator appears.

- You can cancel the tool path computation at any moment before 100% completion.

-

Click OK to create the operation.

Note: If your PP table is configured with the following statement for Sequential Axial operations:

CYCLE/SEQAXIAL, %MFG_TOTAL_DEPTH, %MFG_CLEAR_TIP

A typical NC data output is as follows:

CYCLE/SEQAXIAL, 40.00000, 3.0000

For more information on the parameters available for PP word syntaxes for this type of operation, see NC_SEQAXIAL.