Materials Compliance Management

can import data exported from the chemSHERPA Article Tool or Chemical Tool. The

chemSHERPA Article Tool allows suppliers to enter information about products.

These products are mapped to parts in

Materials Compliance Management.

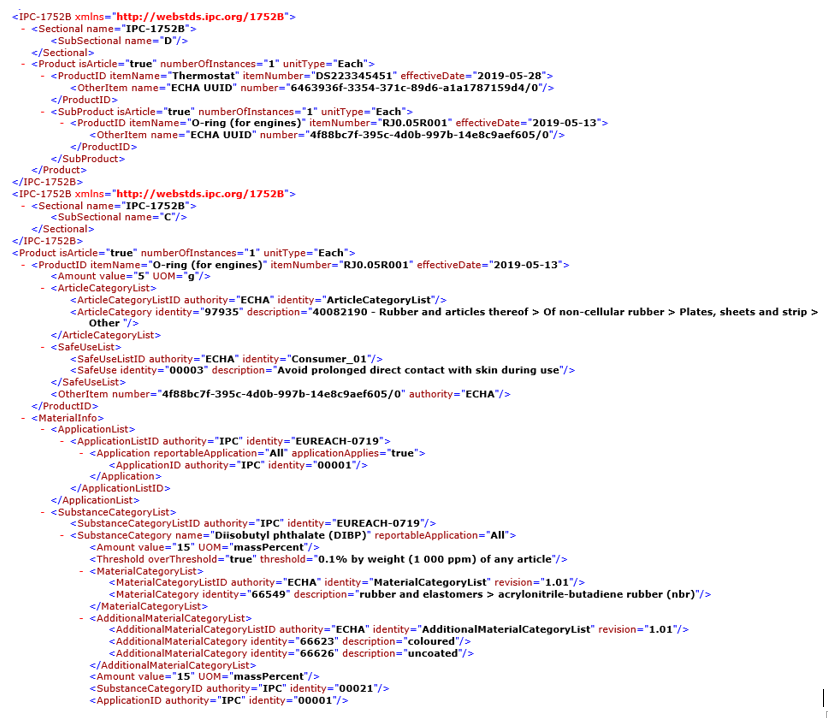

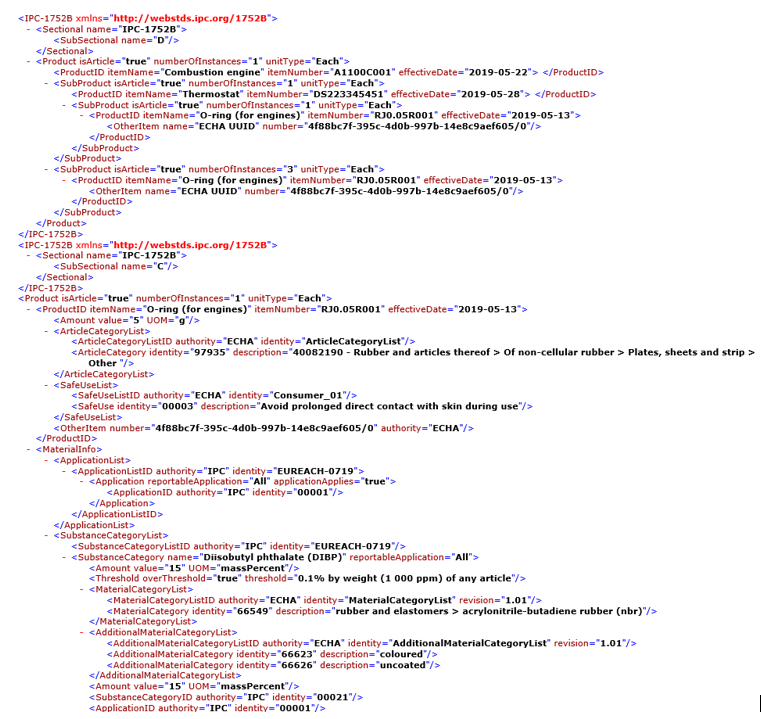

chemSHERPA uses XML files to import and export composition details (components, materials, and

substances) and compliance declarations (thresholds exceeded, exemptions). When more

than one part is involved, the XML files are bundled into a zip file. The chemSHERPA

Article Tool uses the .shai extension and the chemSHERPA Chemical Tool use the .shci

file extension. The zip file can contain up to 100 XML files. If there are more than

100 parts, multiple zip files are used.

When exporting from the chemSHERPA Article tool, the supplier can choose to export composition

information, compliance information, or both types of information. By default, Materials Compliance Management will import files of any of these exports.

However, your Business Administrator can disable either the composition only or compliance only types of imports. When

importing both, your Business Administrator can disable it, or allow importing of only compliance or only composition data.

When importing compliance declarations,

Materials Compliance Management

connects the part to one or more declared thresholds based on the compliance

information. For more information, see

Declared Thresholds.

The chemSHERPA Chemical Tool exports composition information only, not compliance declarations.

The Product exported from the tool is imported to Materials Compliance Management as a material associated with that supplier. If

you want to automatically create MEPs for these materials, you can select the

Auto-Make-Parts check box when configuring the import. In

this case, the app creates a part with the same name as the material title. For more

information, see Configuring Import Options. The app only creates the

MEP if one does not already exist. The app also connects the MEP to a material

declaration (if one exits for the MEP) or creates a new material declaration and

reported part. The reported material is assigned a weight of 1 gram, and the part is

defined as each part with no reference weight. To approve such a material, you

approve the material declaration associated with the MEP of the material. These

materials have no associated exemption information. You might need to edit the

materials before using them in parts.

After importing compliance declarations, the related material

declarations are promoted to Received, and you can run reports to review the

compliance and composition data.

The import attaches these items as Reference Documents for the

material declarations:

- The XML import file (extracted from the zip file)

- The log file for the specific XML file (extracted from the full log

file)

- The full log file

- The full zip file

Materials Compliance Management can be configured to hide private data. If so,

the Authorizer, Issuer, and Requester lists are grayed out when you try to

prepopulate a BOM from either the chemSHERPA Article or Chemical

Tool.

Materials Compliance Management supports the chemSHERPA 2.02 version to import

the data. This version is supported to include the SCIP data.

The SCIP data is included at both the part and threshold levels. The SCIP data is

mapped at part level with the part new attributes for SCIP. The SCIP data is mapped

at threshold levels with the declared threshold attributes.

A new attribute named SCIP Primary Article Identifier is added to Materials Compliance Management to store SCIP Primary Article Identifier. This

attribute is added to enterprise part, plant-specific part, reported part, MEP, and

subtier part to store the information at part level. It is also added to Declared

Threshold to store information at threshold level.

The SCIP data is added in the Comment attribute at each level. The following are

changes for each area:

Product

This is the top-level part and it is mapped to the MEP for Materials Compliance Management. The SCIP data at part level is stored in the

Comment attribute of <Product> XML element. The value of this attribute is

updated as mentioned below. The items 1–8 are from the previous version. The items

9–15 are for the SCIP data for the chemSHERPA v2.02 version. All the items are

separated using the character @.

- Compliance Input Status

- Compliance Finalized Date

- Composition Input Status

- Composition Finalized Date

- Xml Import Status

- Revision Date

- Manufacturer Name

- Comment of Product

- SCIPComplete(Compliance)

- SCIPComplete(Composition)

- Primary Article Identifier

This is mapped to a new attribute SCIP Primary

Article Identifier on part.

- Article Name

This is mapped to the part attribute SCIP Article

Name.

- Article Category

This is mapped to part attribute SCIP Article Category

Identity. MCC will validate and error if the identity is

invalid.

- Production in European Union

This is mapped to part attribute Production

in European Union.

- Safe Use Instruction

This is mapped to the part attribute Safe Use Instructions.

If

the string from the data is “No need to provide safe use information

beyond the identification of the Candidate List substance”, then Materials Compliance Management is specify the ‘Safe Use

Instruction are not required’ check box option.

Composition

- Product Part:

The part is mapped with the Materials Compliance Management subtier part at this

level.

The SCIP data at this level is stored in the Comment

attribute of <ProductPart> XML element. All the items are separated

using the character @.

- Primary Article Identifier

This is mapped to a new attribute SCIP

Primary Article Identifier on part.

- Article Name

This is mapped to part attribute SCIP Article

Name.

- Article Category

This is mapped to part attribute SCIP Article

Category Identity. MCC will validate and error if the identity

is invalid.

- Production in European Union

This is mapped to part attribute

Production in European Union.

- Safe Use Instruction

This is mapped to part attribute Safe Use

Instructions.

If the string from the data is “No need to

provide safe use information beyond the identification of the

Candidate List substance”, then Materials Compliance Management is set the ‘Safe Use

Instruction are not needed’ check box option.

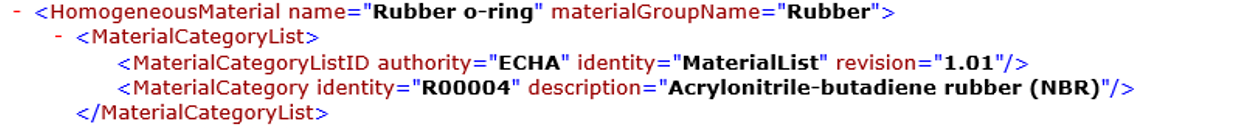

- The SCIP data at part level is stored in the Comment attribute of <Material> XML

element. The value of this attribute is updated as mentioned below. The

items 1–4 are from the previous version. The item 5 is for the SCIP data for

the chemSHERPA v2.02 version. All the items are separated using the

character @.

- chemSHERPA Material Category

- Not Use

- Standard

- Comment

- SCIP Material Category

This is mapped to the material

classification code. Compliance Type is ECHA (which is used from

the properties file parameter setup for ECHA material

classification).

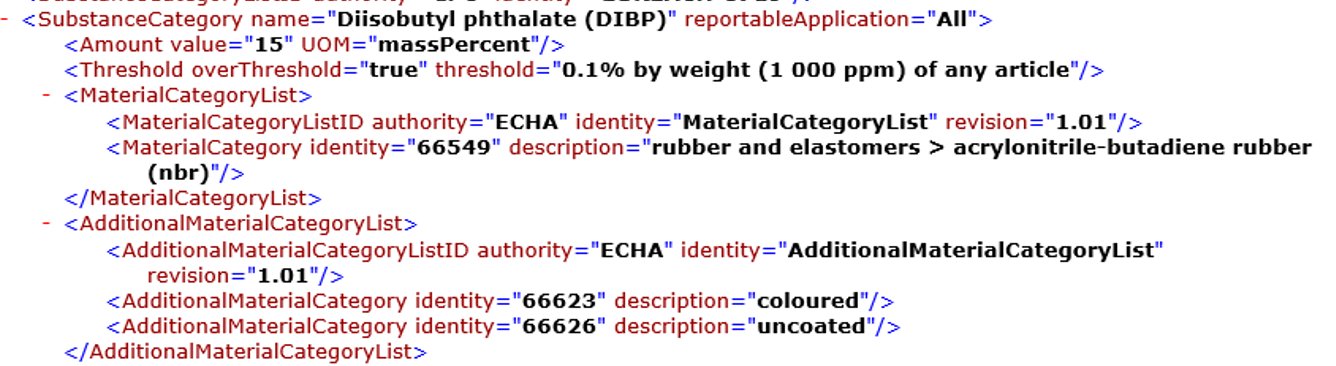

Compliance

Compliance data is imported as the declared thresholds. The attribute Comment for <DsDsg>

XML element is updated to add the SCIP data. The items 1–5 are from the previous

version of chemSHERPA. The items 6-11 are for SCIP data from the chemSHERPA v2.02

version. All the items are separated using the character @.

- Comment

- not use (was Quantity of content on 1.07)

- not use(was Unit on 1.07)

- Usage

- Portion used

- Primary Article Identifier

This is mapped to a new attribute SCIP Primary

Article Identifier on the declared threshold.

- Article Name

This is mapped to the declared threshold attribute SCIP

Article Name.

- Article Category

This is mapped to the declared threshold attribute SCIP

Article Category Identity.

- Production in European Union

This is mapped to declared threshold

attribute Production in European Union.

- Safe Use Instruction

This is mapped to the declared threshold attribute

Safe Use Instructions.

- Material Category

There are no or more than one material

categories.

Each category is mapped to material classification

code for Materials Compliance Management.

Compliance Type is ECHA

(used from the properties file parameter setup for the ECHA material

classification).