About Systems and Operations | |||||||

|

| ||||||

Overview of Systems

Systems can be created from the context toolbar. The available systems are:

- General System

: Used to model the general system.

: Used to model the general system. - Transformation System

: Used to model the transformation of products.

: Used to model the transformation of products. - Transfer System

: Used to model the transportation of products between systems. Transfer operations for a product are defined by associating the corresponding manufactured item to a transfer system. The product spends the specified time on the system before it is routed to the downstream systems. As with Buffer systems, Transfer systems have product capacity.

: Used to model the transportation of products between systems. Transfer operations for a product are defined by associating the corresponding manufactured item to a transfer system. The product spends the specified time on the system before it is routed to the downstream systems. As with Buffer systems, Transfer systems have product capacity. - Buffer System

: Used to model for storing the products. Attributes like capacity, reordering rules, and routing order can be defined on this system.

: Used to model for storing the products. Attributes like capacity, reordering rules, and routing order can be defined on this system. - Capacity: Is the maximum number of products that can be stored in the system at any time.

- Reorder Level: Is number of products that triggers a request for products from the upstream systems. The Buffer system does not make a request for more products when the number of products in the system are greater than the reorder level.

- Routing Order: Defines the order in which products are routed out of the system. The two common types of routing orders are First In First Out (FIFO) and Last In First Out (LIFO).

- Source System

: Used to model the arrival of products into the production system. Properties like arrival mode and arrival type can be defined on this system.

: Used to model the arrival of products into the production system. Properties like arrival mode and arrival type can be defined on this system. - Sink System

: Used to model dispatching of products from the production system processed by the upstream systems.

: Used to model dispatching of products from the production system processed by the upstream systems.

You can also insert existing systems in your system structure by clicking Insert an Existing System ![]() in the context toolbar. For more information, see Inserting an Existing System

in the context toolbar. For more information, see Inserting an Existing System

Create System-Manufactured Item Scope

Create System-Manufactured Item scope

![]() assigns a scope between General system and a Manufacturing Assembly. If the scope is not assigned to the root manufactured item, a warning message appears.

assigns a scope between General system and a Manufacturing Assembly. If the scope is not assigned to the root manufactured item, a warning message appears.

Overview of Operations

You can create operations by right-clicking a system and selecting the required operation type from the Insert context menu or using General Operation from the Authoring section of the action bar. The following operations are available:

- Source Operation: defines the properties of products arriving in a production system through a Source system.

- Sink Operation: defines the properties of products leaving a production system through a Sink system.

- Buffer Operation: defines the properties of products to be buffered at various points in a production system through a Buffer system.

- Interrupt Operation: defines the properties of

failures occurring in a system.Note: This operation is also available from the General system context toolbar.

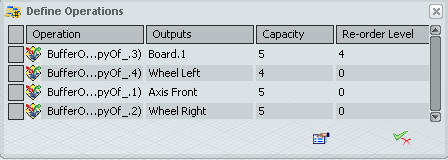

Define Operations

You can define operations by right-clicking in a system and selecting

Define Operations.

The Define Operations

dialog box appears with operations listed.

Edit System Properties

You can modify the system properties by right-clicking in a system in the System Editor and selecting Properties to edit the reference, instance, configuration, and effectivity attributes of a system. For more information, see Edit System Properties.

Delete a System

You can delete a system by right-clicking in a system and select Delete from the context menu. See Delete a System.

Product Flow Links

You can create the product flow links between two systems in the System Editor. See Defining Product Flow Between Systems.

Drag

You can drag manufactured items from the Manufactured Item Editor to assign them to systems in the System Editor to create operations on the target systems.

Switch between Different Frames

You can switch the lower frame of the System Editor to the PPR context. For more information, see Switch between Different Frames.

Simulation of a General System in Push Mode

In previous releases, all the operations of a general system were processed at the same time in Push mode. As from this release, operations are processed separately, if they belong to a different root process (model).

Once the general system cycle is complete, a model is selected according to the inputs available in the upstream system. For instance, if the PPR Context contains three models (A, B, C), model A is automatically processed once the general system cycle is complete, only if the required inputs are available. If model A does not have the required inputs, but model B does, then model B is automatically processed.

F5 Key

Press the F5 key to list information about the system's assigned parts, manufactured items, operations, and fasteners. For more information, see Show Assigned Data Using the F5 List.