Generate the NC Code Interactively

You can generate the NC Code interactively.

-

Select

Generate NC Code

Interactively

.

The Generate NC Output Interactively dialog box is displayed. See Generate the NC Code Interactively

.

The Generate NC Output Interactively dialog box is displayed. See Generate the NC Code Interactively - Define the Input.

- Define the resulting NC Data.

- Define the Tool motions. Go to Tools Motions tab and Formatting

if you need to modify locally the machine parameters.

See Working with Generic Machine Editor.

- When required, go to NC Code tab to specify a post-processor.

-

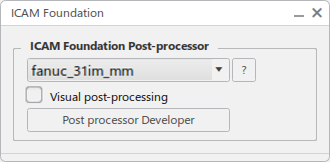

If not already done, go to the Numerical Control tab of

the machine to select the Post Processor Provider or

Me

> Preferences > App Preferences > Simulation > Machining

> NC Machining Apps Common Services > Output to select the type of Post Processor (Cenit,

Intelligent Manufacturing Software (IMS), ICAM Technologies Corporation, or ICAM

Foundation or My Post).

> Preferences > App Preferences > Simulation > Machining

> NC Machining Apps Common Services > Output to select the type of Post Processor (Cenit,

Intelligent Manufacturing Software (IMS), ICAM Technologies Corporation, or ICAM

Foundation or My Post).

-

If not already done, go to the Numerical Control tab of

the machine to select the Post Processor Provider or

Me

-

Select Execute to generate

the NC Code file.

The NC Code Generation progress bar is displayed with the Machining Operations being processed for output and the percentage of progress. The errors and warnings are also displayed in the NC Output Errors and Warnings dialog box.

- Go to

Me

> Preferences > App Preferences > Simulation > Machining

> NC Machining Apps Common Services > Output and select No. of Errors and warnings checkbox.This helps to configure the output generation stopped after the number of errors and warnings crossed a certain value.

> Preferences > App Preferences > Simulation > Machining

> NC Machining Apps Common Services > Output and select No. of Errors and warnings checkbox.This helps to configure the output generation stopped after the number of errors and warnings crossed a certain value. - Select Cancel in the NC Code Generation progress bar to stop the output generation.

- Select OK in the message that is displayed.This message indicates whether the output generation was successful or not. If there are errors or warnings while generating the NC output, the message indicates the number of errors/warnings.

- Select Display errors and Display warnings check box in NC Output Errors and Warnings dialog box to view errors and warnings generated during output generation.

- Select error or warning in NC Output Errors and Warnings dialog box to highlight the Machining Operationin Activities Process

Tree.This helps to edit the Machining Operation and perform correction, as required.

- Select Close to exit the NC Output Errors and Warnings dialog box.

- A NC Files Container named _Manufacturing_Program_x is created under the Manufacturing Cell.

- It contains the NC Code file and a log file. Note: The log file contains machining time information similar to that obtained during the interactive Display or Simulate, as well as warning/error message entries.

If the Activate Collision Checking check box is selected in the Part Operation dialog box (see Creating a Part Operation ), the log file indicates whether any collisions have been detected.

- The Results tab appears in Generate NC Code Interactively dialog box.

- Go to

Me