Before You Begin

Before starting the app,

make sure that the Persist Resource Position check box is

selected. This option is available in

.

Note:

The app performance may vary depending on the type of part used. Do not use parts

containing lattices.

About the Help Icon

The Help icon is available in most dialog boxes. It

displays visual representations of the various parameters available.

From any dialog box, click Help

to display a 3D

representation of the parameters available in the work area. to display a 3D

representation of the parameters available in the work area.

Machine Customization

You can import a DLL file to associate it with the machine in session and display

a list of services. You can also create a virtual machine based on DLL files provided

by machine vendors.

Native Services or Virtual Machine Services

You can import a DLL file to associate it with the machine in session. You can

then display a list of services that you can add to or override the native

services of the application. You can choose between using native or virtual

machine services. The services available are as follows:

- Add or edit rules.

- Best orientation computation: Specify an orientation in which to print a

given part.

- Nesting computation: Position

the parts to print in the build envelope of the machine for a given set

of parts and number of instances required.

Note:

You can show the build envelope as a cube surrounding a machine

with Hide/Show Build Envelope

in the Setup section of the action bar. in the Setup section of the action bar.

Specify the value of the build envelope in the

Rectangular Build Envelope section of

the Reference Parameters dialog box.

- Scan path generation: Compute

and order the scan path for a set of parts (and their supports) inside

the build volume of the machine.

- Post processor services:

Translate the geometry, slices, or scan path into a file that you can

send to the machine to start the print.

Before importing the DLL file, you must create a reference DLL file implementing

the following API:

int ComputeScanPathInAZone(const char* iParamsAsXML, const Object* iSlice,

Object *& oScanPath)

A file containing the API is available in

<V6_install_dir>\startup\Additive\ExternalServices.h.

The table below lists the parameters to define in the reference DLL file:

| Parameter |

Description |

iParamsAsXML

|

Input parameter that corresponds to the

XML content. The content describes the parameters to use for

computation. |

iSlice

|

Input parameter that corresponds to the

C-structure. The structure contains the geometry of the zone

where to generate the scan path and other parameters.

|

oScanPath

|

Output parameter that corresponds to the

structure containing the generated path. |

Virtual Machine

You can create a virtual machine based on DLL files provided by machine vendors.

The services available are as follows:

- Best orientation computation: Specify an orientation in which to print a

given part.

- Nesting computation: Position the parts to print in the build envelope

of the machine for a given set of parts and number of instances

required.

- Scan path generation: Compute and order the scan path for a set of parts

(and their supports) inside the build volume of the machine.

- Post processor services: Translate the geometry, slices, or scan path

into a file that you can send to the machine to start the print.

You can also associate a configuration file to virtual machines. Click a

configuration file from the Configuration File list under

the Services

tab in the Reference Parameters dialog box. You can edit the

files available in the Configuration File list under .

Note:

Configuration files may be required to connect the virtual machine to a

third-party software.

Managing Machine Vendor Rules

When creating rules with the virtual machine, you can update the list of rules

declared on the machine using the associated machine vendor DLL files. Click

Update List of Rules under the

Rules

tab in the Reference Parameters dialog box.

Note:

Rules that come from machine vendor DLL files are considered external

rules. You cannot add or remove external rules defined on the virtual

machine. You can only browse and partially edit them. Some native services

may no longer be available when external rules are applied.

Scanning Optics Definition

You can define scanning optics to manage lasers during the printing simulation

process. You can give each parameter an associated Name

and ID, which appears in the Scanning

Optics dialog box.

Trajectories generated by the scan path computation are optimized based on each

laser's parameters and position. These new trajectories are stated in the output

files.

- Scanning Optics Parameters

- The following parameters are available:

| Parameter |

Description |

| Max Scan

Speed

|

Specifies the maximum scanning

speed. By default, the value is 10m/s. |

| Max Scan

Power

|

Specifies the maximum scanning

power. By default, the value is 600W. |

| Max Jump

Speed

|

Specifies the maximum jump speed.

By default, the value is 10m/s. |

- Beam Parameters

-

The following Beam parameters are available:

| Parameter |

Description |

| Focal

Diameter

|

Specifies the beam focal

diameter. By default, the value is 0.2mm. |

| Maximal Defocusing

Length

|

Specifies the maximum

defocusing length. By default, the value is 0.1mm.

|

- Scope Parameters

- Depending on the Shape Type selected (rectangle

or circle), the following parameters are available:

-

| Rectangle |

Circle |

|

| Parameter |

Description |

| Length

|

By default, the value is the

difference between the minimum and maximum Y

value. |

| Width

|

By default, the value is the

difference between the minimum and maximum X

value. |

|

| Parameter |

Description |

| Radius

|

By default, the value is:

150mm. |

|

- You can edit these parameters directly in the work area.

- Mirror Mounting Point Parameters

- You can also define the Mirror Mounting Point

using the X, Y, and Z coordinates. This is in the top center of the

build envelop by default.

Chamber

You can define chamber parameters to specify parameters for the additive

machine.

| Parameter |

Description |

| Gas Inlet Direction

|

Direction of the gas. By default, the value is

along the x-axis (value = 0). |

| Gas Inlet Distribution

Type

|

Distribution of the gas in the build chamber:

lateral or from center to border. |

| Gas Inlet Area |

Area of the entrance of the gas in the build

chamber. |

Exclusion Zones

Exclusion zones are zones on the build tray or on a part that are designated as zones

free of machining. Zones defined as exclusions zones remain in the database while

saving data and can be associated to a rule.

You can define exclusion zones on a part using the Edit Exclusion

Zones

command

from the Build Layout dialog box. This command opens the

exclusion zone panel and displays the exclusion zone context toolbar. command

from the Build Layout dialog box. This command opens the

exclusion zone panel and displays the exclusion zone context toolbar.

The exclusion zone panel contains a list of current exclusion zones.

The exclusion zone context toolbar allows you to free-form draw or generate a predefined shape as an exclusion zone.

When a new exclusion zone shape is created using the context toolbar, it appears on the build tray and is projected along the z axis up to the maximum

height of the machine to create a solid body. You can use the Robot to edit the shape and its placement on the build tray.

For more information, see Commands Accessible from Exclusion Zone Creation and Positioning the Parts on the Build Tray.

Regions

Regions are volumes that you can define on a part. It is useful to define regions if

you plan to generate a different slicing and scan path on specific volumes of a

part.

To create a region, you must select a closed volume that corresponds to a physical

product. It is only possible to define regions if the part contains two or more

physical products.

For more information, see Adding Regions.

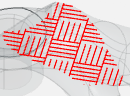

Scan Path

You can generate a scan path for laser or electron beam fusion methods. It is

possible to generate several scan paths for the same part.

You can choose between the following types of scan path:

| Contouring |

Hatching |

Stripe |

Chessboard |

|

|

|

|

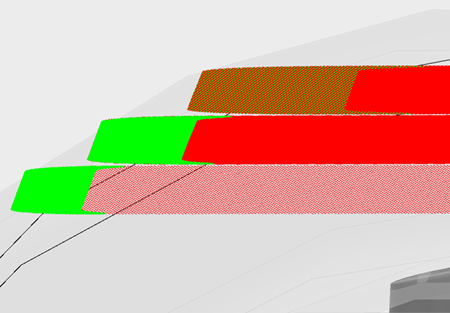

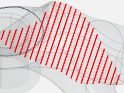

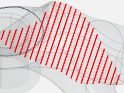

The difference between the Hatching and Stripe scan paths depends on the direction of

the path progression, identified by the blue arrow below:

| Hatching |

Stripe |

|

|

Rule Parameters

Depending on the scan path selected, the following parameters are available in

the Global Parameters, Compose

Strategy, and Scan Path Order

tabs:

- Global Parameters

-

The Global Parameters

tab lets you detect slicing, upskin, and downskin.

- Scan Path Rule: Name of the scan path rule.

- Slicing step: Specifies how the part is cut along

the z axis. By default, the value is 0.1mm.

-

| Downskin |

Upskin |

|

| Parameter |

Description |

| Minimal Skin

Width

|

The specific value that a

surface is considered downskin. By default, the

value is 1mm. |

| Number of

Layers

|

The specific number of

downskin layers. By default, the value is

1. |

| Restrict Core by

Downskin

|

If set to

True, the scan path for the

core does not overlap the scan path for downskin.

|

|

| Parameter |

Description |

| Minimal Skin

Width

|

The specific value that a

surface is considered upskin. By default, the

value is 1mm. |

| Number of

Layers

|

The specific number of

upskin layers. By default, the value is 1. |

| Restrict Core by

Upskin

|

If set to

True, the scan path for the

core does not overlap the scan path for upskin.

|

|

- Compose Strategy

- The Compose Strategy

tab contains the scan path definitions in each zone of application: Core,

Downskin, and Upskin.

- Zones Type: Core,

Downskin, and

Upskin.

| Contouring |

In Fill |

|

| Parameter |

Description |

| Depth

|

Orders the definitions from

the most external one to the most internal one

inside a zone. |

| Definition

|

Name of the

definition. |

| Periodicity

|

Specifies the frequency of the scan path to apply

to the slices. By default, the value is 1

(integer).

|

| Start

|

Index of the first slice from which the

definition is applied. |

| Range

|

Specifies a number of slices

on which the scan path definition applies.

|

| Action |

Action available on the definition. You can

edit  or delete or delete  the definition. the definition. |

|

| Parameter |

Description |

| Depth

|

Orders the definitions from

the most external one to the most internal one

inside a zone. |

| Definition

|

Name of the

definition. |

| Periodicity

|

Specifies the frequency of the scan path to

apply to the slices. By default, the value is 1

(integer).

|

| Start

|

Index of the first slice from which the

definition is applied. |

| Range

|

Specifies a number of slices

on which the scan path definition applies.

|

| Action |

Action available on the definition. You can

edit  or delete or delete  the definition. the definition. |

|

- Definition Parameters

- Scanning Rule: Lists the existing scanning rules

that you can link to the scan path definition inside the scan path

rules. You can create a new scanning rule here if a rule does not

already exist.

- Contouring:

| Contouring XY Strategy |

Contouring Z Strategy |

|

| Parameter |

Description |

| Number contouring

pass

|

Specifies the number of

contouring passes to create. |

| Radial

step

|

Specifies the space between two consecutive

paths of the same scan path. By default, the value

is 0.1mm.

|

| Offset from last

contouring

|

Specifies the space between

the last contouring pass of the previous scan path

and the current scan path. By default, the value

is 0mm. |

| Random starting

point

|

Starts the scan path at a random point of

the contouring trajectory. |

| From inner to

outer passes

|

If more than one contouring

pass is defined, start the scan path from the

inner pass to the outer one. |

|

| Parameter |

Description |

| Periodicity

|

Specifies the frequency of the scan path to

apply to the slices. By default, the value is 1

(integer).

|

| Apply on a Range

of Slice

|

Applies the scan path

definition to a certain number of slices. By

default, the definition applies to all the slices

starting from the value specified for the

Starting slice

parameter. |

| Starting

Slice

|

Specifies a number of slices

on which the scan path definition applies.

|

| Range of

Slice

|

Specifies a number of slices

on which the scan path definition applies. |

|

- In Fill

| Hatching |

Stripe |

Chessboard |

|

| Parameter |

Description |

| Infill

mode

|

Specifies the scan path

mode, such as back and forth, or one way. |

| Angle rotation

between slices

|

Specifies a rotation angle

between a given slice and the previous or next

one. This is useful to alternate the direction of

hatching for example . |

| Hatching

Direction

|

Direction of the hatch

pattern when applied for the first time. By

default, the value is 0. |

| Radial

step

|

Specifies the space between

two consecutive paths of the same scan path. By

default, the value is 0.1mm. |

| Offset from last

contouring

|

Specifies the space between

the last contouring pass of the previous scan path

and the current scan path. By default, the value

is 0mm. |

|

| Parameter |

Description |

| Infill

mode

|

Specifies the scan path

mode, such as back and forth, or one way. |

| Angle rotation

between slices

|

Specifies a rotation angle

between a given slice and the previous or next

one. This is useful to alternate the direction of

hatching for example . |

| Stripe angle to

Hatching direction

|

Angle of the stripe toward

the hatching direction. By default, the value is

90 degrees. |

| Hatching

Direction

|

Direction of the hatch

pattern when applied for the first time. By

default, the value is 0. |

| Stripe

width

|

Distance between two

consecutive red dotted lines. |

| Radial

step

|

Specifies the space between

two consecutive paths of the same scan path. By

default, the value is 0.1mm. |

| Offset from last

contouring

|

Specifies the space between the last contouring

pass of the previous scan path and the current

scan path. By default, the value is 0mm.

|

|

| Parameter |

Description |

| Infill

mode

|

Specifies the scan path

mode, such as back and forth, or one way. |

| Angle rotation

between slices

|

Specifies a rotation angle

between a given slice and the previous or next

one. This is useful to alternate the direction of

hatching for example . |

| Stripe angle to

Hatching direction

|

Angle of the stripe toward

the hatching direction. By default, the value is

90 degrees. |

| Hatching

Direction

|

Direction of the hatch

pattern when applied for the first time. By

default, the value is 0. |

| Square

size

|

Length of the square.

|

| Radial

step

|

Specifies the space between

two consecutive paths of the same scan path. By

default, the value is 0.1mm. |

| Offset from last

contouring

|

Specifies the space between

the last contouring pass of the previous scan path

and the current scan path. By default, the value

is 0mm. |

|

- Scan Path Order

- The Scan Path Order

tab lets you modify the order of the scan paths.

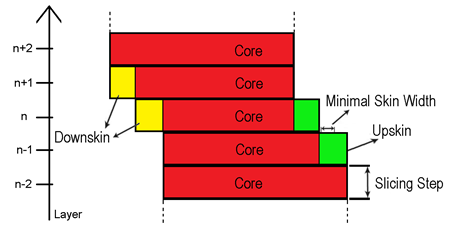

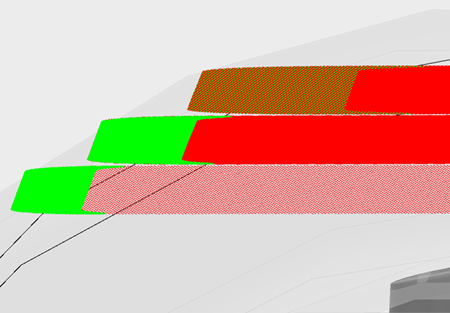

Skin Surfaces

A skin surface is an area on a layer of a part, with no material above or

below.

There are several types of skin surfaces:

- Upskin: upward facing surface of a

part with no material above.

- Downskin: downward facing surface

of a part with no material below.

- Core: corresponds to the surface

between an upskin and downskin surface.

Skin surfaces are automatically detected on a part when you create a scan path rule

in the Scan Path Definition Sequence

tab.

You can generate a scan path on any type of skin surface using the general scan path

parameters, and order them in a sequence. For more information, see Scan Path.

For each surface, the following colored scan paths are generated:

- Red for core surfaces

- Yellow for downskin surfaces

- Green for upskin surfaces

Note:

The parts and supports are not highlighted.

Scan paths with different definitions might overlap each other. In this case, only one color

is displayed. Zoom-in on the colored scan path to check that the color displayed

corresponds to one scan path only.

The following skin surfaces parameters are available:

| Parameter |

Description |

| Minimal Skin Width

|

The specific value that a surface is considered

upskin or downskin. By default, the value is 0.1mm. |

| Number of Layers

|

The specific number of upskin or downskin layers.

|

| Restrict Core by Downskin

|

If set to True, the scan

path for the core does not overlap the scan path for downskin or

upskin. |

Scan Path Analysis

You can do an analysis to compare the trajectory of the scan path with the design of

the part.

- Geometrical Parameters

-

| Slices

|

Part Display With

Transparency

|

Error Detection

Range

|

|

| Parameter |

Description |

| Bottom

|

Specifies the bottom slice

width. |

| Top

|

Specifies the top slice

width. |

|

| Parameter |

Description |

| Design

Part

|

Specifies the visibility and

transparency of the design part. |

| Manufactured

part

|

Specifies the visibility and

transparency of the manufactured part. |

|

| Parameter |

Description |

| Low-Melting

Detection

|

Specifies the value for a

low-melting error point. |

| Roughness

Detection

|

Specifies the value for a

roughness (extra material) error point. |

|

- Section

Specifies sectioning on the part to see inside of the part for each

slice.

- Physical Parameters

- Activate Physical Analysis

-

| Powder |

Chamber |

|

| Parameter |

Description |

| Density

|

Specifies the density of the

powder. |

| Melting

Point

|

Specifies the melting point

of the powder. |

| Porosity

|

Specifies the porosity of

the powder. |

| Absorption

Coefficient

|

Specifies the amount of

energy that the powder can absorb. |

| Diffusivity

|

Specifies the amount of

energy that the powder diffuses. |

| Conductivity

|

Specifies the conductivity

of the powder. |

| Specific Heat

Capacity

|

Specifies the heat capacity

of the powder. |

|

| Parameter |

Description |

| Preheat

Temperature

|

Specifies the preheat

temperature. |

| Pending Time

Before Scanning

|

Specifies the time allotted

for the piece to cool off between passes.

Note:

This parameter includes new powder level

deposition time.

|

|

Supports

Supports stabilize the part during the build process, and reduce residual stress by

improving thermal diffusion during the build. You can select multiple supports at

once using Ctrl and clicking the required supports.

For more information, see Rules for Generating Supports.

Supported Parts

Only STL parts with closed volumes are compliant with the app.

However, if you load an STL part with closed volumes, it is not possible to:

- Compute the orientation of a part

that minimizes the volume of supports.

- Automatically positions the parts on the build

tray using Generate Nesting

. .

Output

You can generate a file containing geometrical and slicing information.

Export Parameters

The following methods are available:

| Method |

Description |

| Geometry without support

structure

|

Exports the geometry with the support

structure. |

|

Geometry with support structure

|

Exports the geometry without the support

structure. |

| Only support

structure

|

Exports only the support structure.

|

Check Build

You can check the build setup by clicking Check Build in

the Generate Output dialog box. The resulting

information is displayed in the Messages Reporting dialog

box.

Generate Documentation

You can generate a shop floor documentation when exporting by selecting

Generate Documentation.

If the Save output(s) in Manufacturing Cell option is

activated, the documentation will be stored in the same NC container than the

output. If not, it will be stored at the same location than the output.

You can generate the documentation along with the output file for the selected position

parts. You can use either a default template or a customized template defined in .

See Customizing Preferences

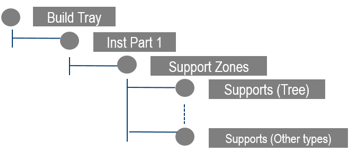

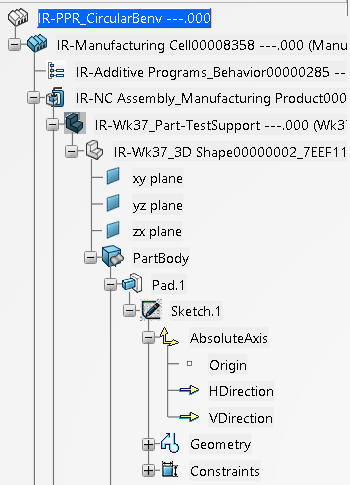

Tree Structure

The additive manufacturing process content is located under a manufacturing cell

in a PPR Context.

Below are examples of the typical structure and content that appear in the tree when working in the app.

The manufacturing cell contains:

- A build tray node with elements

from your working environment.

- An instances node for the parts

positioned on the build tray and a context menu for instance part.

- A support zones node for each instance containing the support features

grouped based on their type of support.

- A support features node for each support zone grouped based on type.

In the tree, you can do the following:

- Multiselect objects and cross-highlight objects from the tree to the work area.

- Select objects in tree during the command scope.

- Sort the supports with a context menu on the build tray based on:

- If there are any supports for the zones, then all the zones with no

supports are grouped together.

- The types of the supports, which could be either edges, point, or

tree.

|