General Framework for Modeling Damage and Failure

Abaqus offers a general framework for material failure modeling that allows the combination of multiple failure mechanisms acting simultaneously on the same material. Material failure refers to the complete loss of load-carrying capacity that results from progressive degradation of the material stiffness. The stiffness degradation process is modeled using damage mechanics.

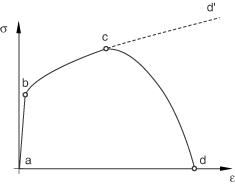

To help understand the failure modeling capabilities in Abaqus, consider the response of a typical metal specimen during a simple tensile test. The stress-strain response, such as that illustrated in Figure 1, will show distinct phases. The material response is initially linear elastic, , followed by plastic yielding with strain hardening, . Beyond point c there is a marked reduction of load-carrying capacity until rupture, . The deformation during this last phase is localized in a neck region of the specimen. Point c identifies the material state at the onset of damage, which is referred to as the damage initiation criterion. Beyond this point, the stress-strain response is governed by the evolution of the degradation of the stiffness in the region of strain localization. In the context of damage mechanics can be viewed as the degraded response of the curve that the material would have followed in the absence of damage.

Thus, in Abaqus the specification of a failure mechanism consists of four distinct parts:

-

the definition of the effective (or undamaged) material response (for example, in Figure 1),

-

a damage initiation criterion (for example, c in Figure 1),

-

a damage evolution law (for example, in Figure 1), and

-

a choice of element deletion whereby elements can be removed from the calculations once the material stiffness is fully degraded (for example, d in Figure 1).

These parts will be discussed separately for ductile metals (About Damage and Failure for Ductile Metals) and fiber-reinforced materials (About Damage and Failure for Fiber-Reinforced Composites).