What's New | ||

| ||

R2022x FD01 (FP.2205)

- You can now access an interactive list of properties, abstractions, and behaviors that allows you to review, modify, and delete these items.

- You can now store relations applied on connection parameters in a connection template.

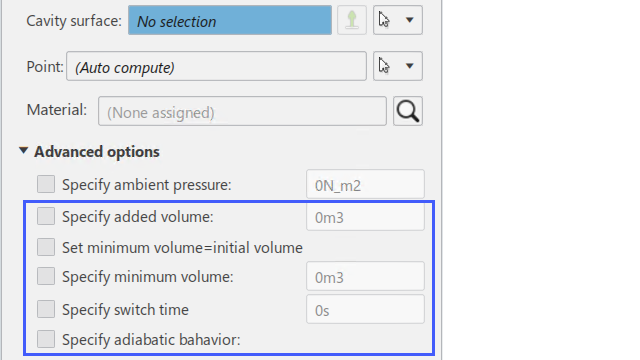

- You can now define the behavior of fluid cavities more effectively using an expanded series of options that provide more flexibility and power.

- The functionality of virtual bolts has been expanded, allowing you to use them in more kinds of models.

- Improvements to connectors options give you access to advanced behaviors, which are supported in connector templates and Abaqus input file import.

- You can now have point fasteners created automatically on part flanges.

- You can now define engineering rules that set connection parameters automatically according to the thickness of the connected layers.

- You can benefit from additional usability improvements when creating point and line fasteners.

- You now have more control over how the coupling restrains relative motions between the connected nodes.

- You can now add color coding to point fasteners so that you can review the fastener connectivity and status directly in the display.

- You can now identify certain types of FEMs by their appearance in the tree.

- You can now rapidly identify all areas throughout the mesh where patterns of rotating quad elements occur.

- You can now directly access the mesh editing tools.

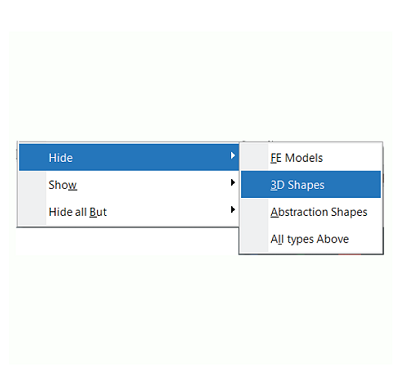

- The enhanced visualization management tool, the Visibility Manager, displays new options for finite element models and uses a more efficient selection method than in previous releases.

Property Manager

Benefits: The Property Manager improves the usability of this app by

helping you edit properties, abstractions, and behaviors more efficiently than

before.

Ability to Store Relations in a Connection Template

Benefits: The ability to store relations in a connection template improves your ability

to create multiple connections efficiently.

Full Coverage for Fluid Cavity Features

Benefits: The expanded options enable you to define fluid cavity behavior that is more

realistic and provides better simulation results.

For more information, see

Defining the Fluid Flow In and Out of Fluid Cavities

Improvements to Virtual Bolt Placement and Definition

Benefits: You can create virtual bolts on more types of geometry and use expanded

constructs to define their behavior.

For more information, see

Defining Virtual Bolts

Detecting Virtual Bolt Locations and Applying Virtual Bolts

Enhanced Connection Behaviors

Benefits: Connectors now have additional advanced behaviors allowing you to design more

realistic models.

For more information, see

Defining Connection Elasticity

Defining Connection Plasticity

Defining Connection Damping

Automatic Point Fastener Creation on Flanges

Benefits: You can save time when creating fasteners on flanges because you do not need

to create additional geometric entities to define the fastener locations.

For more information, see

Defining Point Fasteners

Using Engineering Rules to Define Fastener Dimensions

Benefits: Engineering rules can make fastener creation more efficient by automatically

setting fastener parameters based on the model.

For more information, see

About Rule-Based Fasteners

Defining Rule-Based Fasteners

Usability Improvements for Point and Line Fasteners

Benefits: Fastener creation and fastener detection options are more consistent, and more

responsive dialog boxes minimize obstructions to the model view.

For more information, see

Defining Line Fasteners

Defining Point Fasteners

Specifying the Nodes to Restrain when Using Kinematic Coupling-to-Point Connectors

Benefits: The ability to control how kinematic point couplings restrain the relative

motions between nodes gives you more flexibility and allows you to use the couplings in

a manner consistent with some legacy models.

For more information, see

Coupling Options

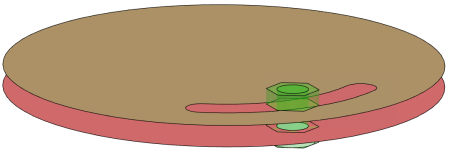

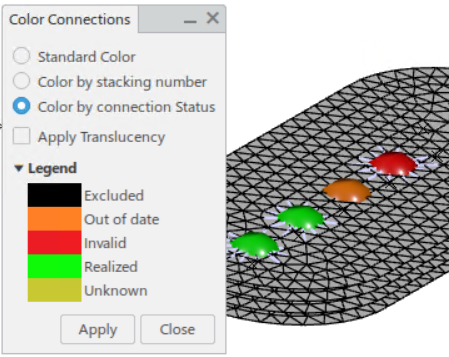

Viewing Fastener Configurations and Status Using Color Coding

Benefits: Color coding helps you quickly check the fastener definitions and locate any

fasteners that need corrections and updates.

For more information, see

Visualizing Connection Properties and Statuses by Color

New Icon Overlays for Finite Element Model Types in the Tree

Benefits: Icons masks make it possible to quickly distinguish FEM types in the tree.

For more information, see

Tree Masks

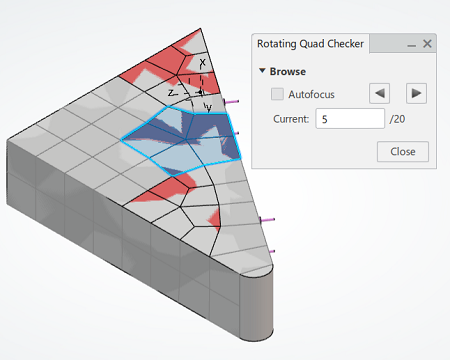

Checking the Mesh Pattern in Transitional Areas

Benefits: You can locate rotating quad patterns to evaluate the quality of your mesh.

While quad meshes are better for structural simulations, they contain rough transitions.

Smoother transitions with more triangles create a better mesh pattern for Explicit

Dynamics analyses.

For more information, see

Identifying Rotating Quads in the Mesh Pattern

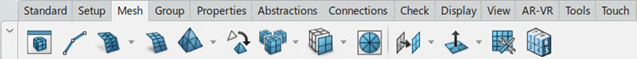

Mesh Navigation and Usability

Benefits: Structural Model Creation users can now access quality analysis without switching apps. These context toolbar shortcuts allow you to switch between meshparts for editing without having to leave

the workbench to edit a different one. This applies not only in the current active FEM,

but also to meshparts that are in the FEM assembly.

For more information, see

Viewing Individual Elements by Quality Criteria

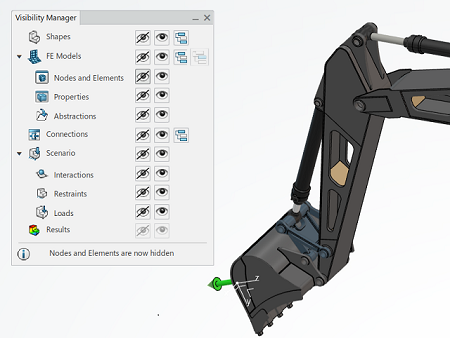

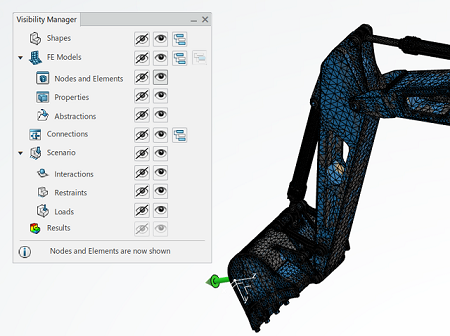

Enhanced Visualization Management

Benefits: The modified Visibility Manager and the enhancements to

the associated context menus reduce the number of clicks you need to activate commonly used options.

For more information, see

Managing the Visualization of Simulation Entities

R2022x GA

- You can now run structural simulations on polyhedral geometry.

- The Lock Domain command has been enhanced and renamed Element Lock.

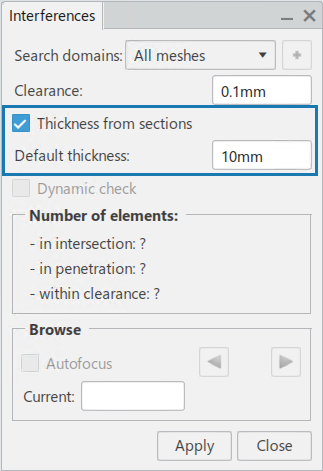

- When you check for interference, you can now account for the thickness of the sections in your model.

- All actions for creating, editing, and reviewing the mesh and finite element model for a simulation are now located in the Structural Model Creation and Fluid Model Creation apps.

- The user interface for the Functional Structure FEM

option now

prevents you from making an invalid selection.

option now

prevents you from making an invalid selection. - Improvements have been made to the procedure for associating composite layup definitions with geometric or mesh parts.

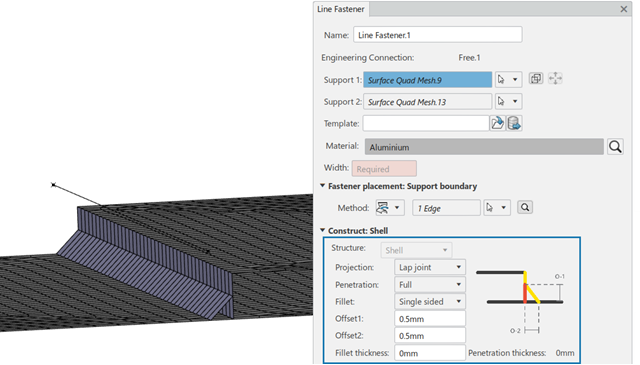

- You can now use line fasteners to model welded lap joints when you use the support boundary placement method.

Simulations with Polyhedral Geometry

Benefits: You can map the simulation properties and loads from the simulation for a CAD

design to an updated, polyhedral version of the same design to verify that the new

design meets the original specifications.

Locking Elements and Domains

Benefits: Locking individual elements or the elements of a selected domain allows you to

modify parts of the mesh while keeping the locked portions unchanged.

For more information, see

Splitting Quadrangles into Triangles

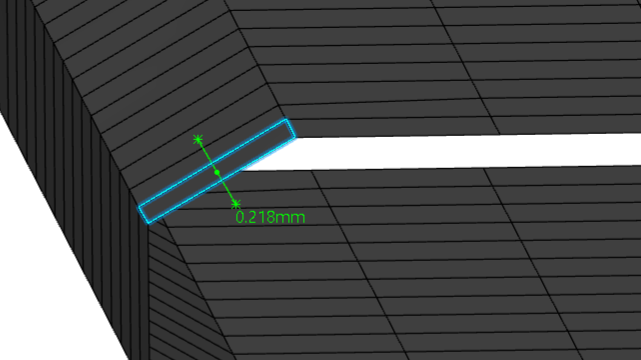

Mesh Interference

Benefits: Adding section thickness to the interference checks accounts for the real

shape of the model, rather than checking the design which is typically at the center of

the thickness.

For more information, see

Checking Interferences

Model and Mesh Unification

Benefits: You can now complete all mesh and finite element model creation and editing

actions within the model creation apps. This provides a seamless interaction with no

need to switch between apps to create the model and mesh features for your

simulations.

For more information, see

Mesh Section

Proxy and Source Selection Guidance for Functional Structure Finite Element Models

Benefits: The improved feedback mechanism improves the user experience for creating a

functional structure FEM.

For more information, see

Creating Functional Structure Finite Element Models

Composite Sections

Benefits: You have more control over the core sampling depth for composite sections and

fewer constraints on the orientation and draping directions.

For more information, see

Defining Composite Shell Sections

Defining Composite Continuum Shell Sections

Meshing Lap Joints

Benefits: You can now use line fasteners to model welded lap joints

efficiently.

For more information, see

Defining Line Fasteners Using the Support Boundary Method

and blocks your selection.

and blocks your selection.