What's New | ||

| ||

R2022x FD01 (FP.2205)

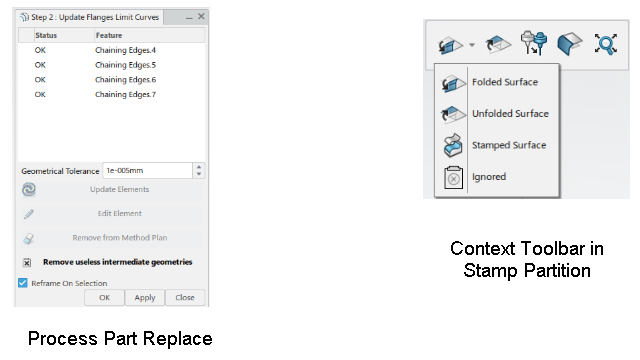

- Die Face Design has been enhanced to better support double-flanges.

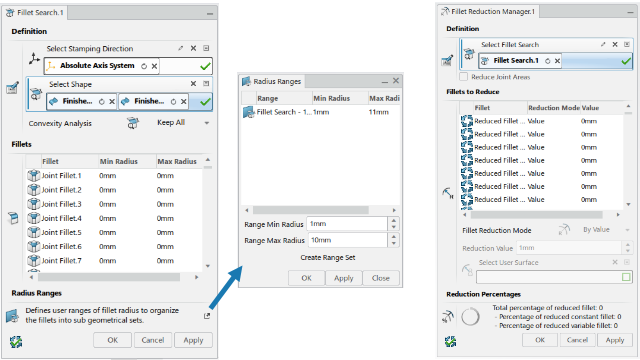

- The commands used to detect fillets and reduce their radius have been replaced by

Support of Double-flanges

Benefits: Double-flange configurations are automatically managed when computing the

unfolded view of a flange in Stamp Partition.

For more information, see

Replacing the Process Part

Creating a Stamp Partition

Using the Process Generator Wizard

Radius Reduction

Benefits: To avoid pinching the sheet of metal between the punch and the die, the

fillets in the die are created by reducing the radius of fillets found in the punch. The

new commands make this process easier and quicker.

For more information, see

Searching Fillets

Reducing the Radius of Fillets

R2022x GA

- You can now use Die Face Design features as result in another app without having access to a Die Face Design license.

- Several commands have been enhanced or created in the Method Plan section to make the update easier.

- The Fill Surfaces command has been renamed into Shut Off Surface.

- Several commands used in the process have been created or enhanced as explained below.

- This command has been enhanced with an auto-pilot mode, proposed by default, that uses min G2 and G1 lengths to compute the extensions.

- The selection in Connect Surface has been simplified.

- This new command fills gaps between surface extensions. In particular, it can fill complex holes.

- Three commands have been added

- This new command creates a manager feature that analyzes the boundary, and creates children features that are boundaries of different types.

- This new command creates a manager feature to compute extensions in a simple and effective way.

- Several commands have been enhanced or created in the Method Plan section to make the design easier.

- This section has been completed with three commands.

- Several Die Face Design features have been exposed, to allow the definition of advanced knowledge expert rules to validate a method plan.

Die Face Design Features

Benefits: You can use the features as geometrical results, within any role.

Update of the Process after a Design Part Change

Benefits: The update of the process after a design part change is done quickly, with a

minimum of user interactions.

For more information, see

Assign Geometries to Operations

Using the Detailed Geometry Wizard

Computing All Unfolds

Creating a Cam Direction

Defining a Process Step

Creating a Concept to Detail Link

Creating a Detail to Detail Link

Creating a Detail to Result Link

Managing BReps Links

Replacing the Detailed Process Part

Replacing the Process Part

Performing a Bulk Upgrade

Chaining Edges

Shut Off Surface

Benefits: Shut Off Surfaceis now compatible with Solidworks

XMold.

For more information, see

Filling Holes on Surfaces

Creation of Extension Surfaces

Benefits: The process has been enhanced to be quicker, with fewer interactions and more

stable.

For more information, see

About the Extension Process

Surface Extension

Benefits: The auto-pilot mode makes the creation of extensions quicker and more stable,

and is part of the improvement of the extrapolation process.

For more information, see

Creating a Surface Extension

Connect Surface

Benefits: This command provides three modes to fill holes, automatically or manually,

and is suitable to fill greater areas. It also reduces the number of manual actions,

thus making the process quicker.

For more information, see

Creating a Connect Surface

Fillet Connect

Benefits: This command provides three modes to fill holes, automatically or manually,

and is suitable to fill greater areas. It also reduces the number of manual actions,

thus making the process quicker.

For more information, see

Creating a Fillet Connect

About Fillet Connect

Prehem Surface

Benefits: They make the creation of prehem surfaces easier.

For more information, see

Creating a Boundary Partition

Creating a Variable Offset Curve

Creating a Fillet Based Projected Curve with an Angle

Boundary Analysis

Benefits: This new command is part of the improvement of the extrapolation

process.

For more information, see

Creating a Boundary Analysis Manager

Surface Extension Manager

Benefits: This new command is part of the improvement of the extrapolation

process.

For more information, see

Creating a Surface Extension Manager

Process Design

Benefits: This makes the process design quicker, with fewer interactions .

For more information, see

Administration: Managing Standards

About Die Face Design Standards

Using the Process Generator Wizard

Creating a Process Method Plan

Positioning the Part

Computing the Boundaries of the Flange

Generating the Structure

About Die Face Design Standards

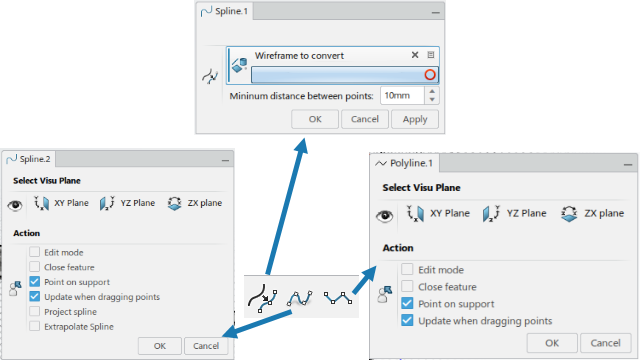

Selection Tools

Benefits: The direct manipulation of 3D Splines and Polylines in the 3D area is

improved.

For more information, see

Converting a Wireframe to a 3D Spline

Creating a 3D Spline

Creating a 3D Polyline

Data Model Exposure

Benefits: Die Face Design features are exposed and accessible for knowledge as specific types. You can write

your own Knowledge Expert rules to validate a complete method plan, making the process

of collaborating with suppliers easier. OEMs may delegate the concept process definition

to suppliers, and when they receive it back, they can fully validate it through in-house

knowledge rules.

For more information, see

About Die Face Design and Knowledge